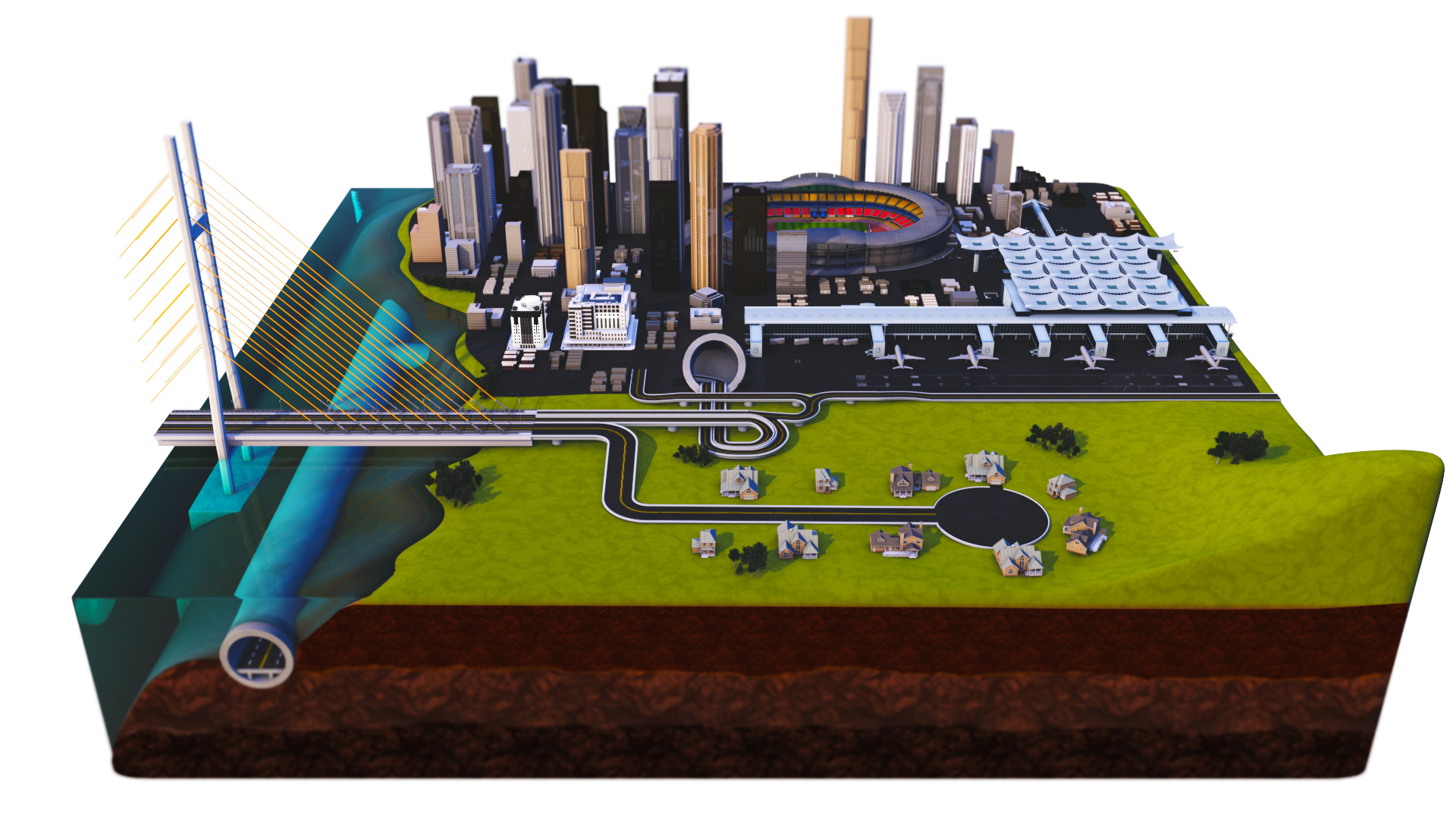

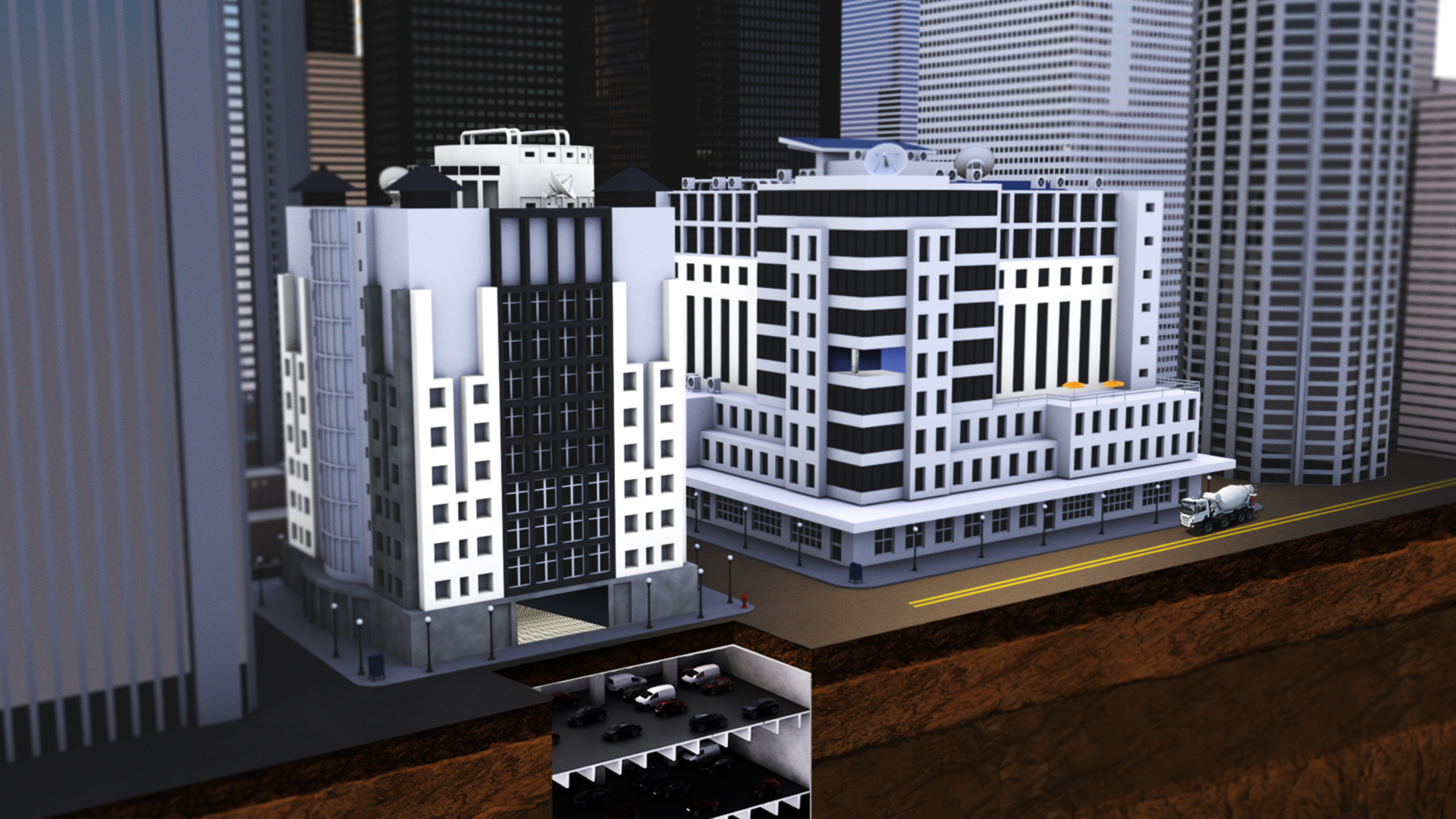

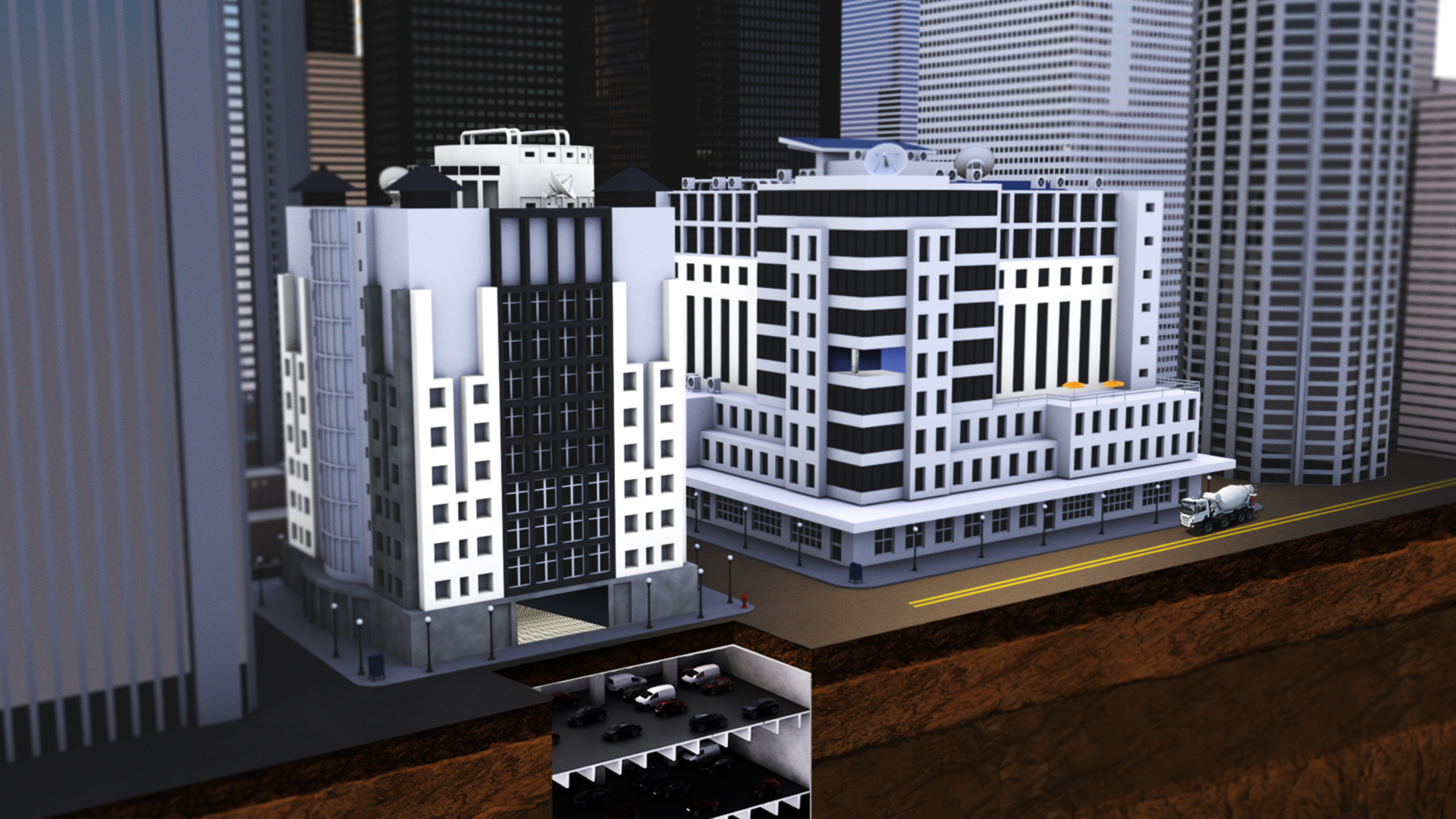

Commercial Buildings Hotspot

From waterproofing to concrete technology, we have what you need to construct durable, sustainable, beautiful commercial buildings.

Fireproofing

MONOKOTE® fireproofing has been used in some of the world's biggest projects, including the MGM City Center in Las Vegas and New York City's Freedom Tower. Much more than a code-compliant product, MONOKOTE® fireproofing prevents or slows down the failure of steel and concrete threatened by fire. These life-saving materials give first responders additional time to evacuate occupants and preserve the building from further, costly damage.

Typically, MONOKOTE® materials are spray-applied, making it easy for contractors to pump them into the upper reaches of the tallest skyscrapers.

Admixture Products

For decades, construction teams worldwide have relied on ADVA® products to make and place durable, resilient concrete for their commercial buildings. In addition to providing superior water reduction, ADVA® admixtures generate higher compressive strengths, better slump retention, improved rheology, enhanced air control and appealing finishability. In addition, they impart strength and durability across a wide range of materials, including flowable and self-consolidating concrete.

Flooring for Commercial Buildings

Producers add CONCERA® admixtures to supercharge their concrete, using ordinary materials and conventional mix proportions. The result is high flowing ready mix concrete that resists segregation at a more competitive price point. Its flowability means easier placement and faster completion times.

GCP has also created numerous materials that make ready mix stronger and crack resistant. STRUX® synthetic macro fibers help contractors speed up construction by decreasing the thickness of slab on grade or overlays, while ECLIPSE® liquid admixtures sharply decrease drying shrinkage, cracking and curling in concrete.

GCP also provides KOVARA® a floor moisture barrier consisting of a sheet membranes designed to be laid down above the concrete slab but underneath floor coverings, including carpet, vinyl, ceramic tile and more. It's designed to protect these materials as well as their adhesives from any staining, warping or mold that may result from water or alkaline salts infiltrating through the concrete slab.

Air Barriers

PERM-A-BARRIER® air barriers and flashing protect your building envelope from uncontrolled air and associated moisture that can lead to mold and other damaging problems. PERM-A-BARRIER® fully-bonded membranes are NFPA 285-compliant, meeting rigorous requirements of protecting the largest buildings. PERM-A-BARRIER® products come in permeable or non-permeable solutions and fluid-applied or sheet-applied systems for quick, no-fuss installation.

Waterproofing

Engineers specify SILCOR® liquid waterproofing solutions to protect podium decks, green roofs and terraces. Due to their strength, flexibility and durability, SILCOR® materials have been used in high-profile projects, including Pruva 34 in Istanbul and Crossrail in London. SILCOR® liquid membranes conform to nearly every surface, seamlessly handling complex shapes and detailing.

Below-Grade Waterproofing

PREPRUFE® pre-applied waterproofing membranes and DE NEEF® injectable grouts protect foundations against water infiltration and prevent leaks from delaying construction. PREPRUFE® membranes form a tough, permanent and aggressive bond with any concrete slab or wall. Independent testing shows that PREPRUFE® membranes resist lateral water migration at extremely high pressure. Additionally, they’re easy to install.

The DE NEEF® line of injectable grouts is the perfect companion to PREPRUFE® membranes. These grouts quickly and permanently stop leaks in any part of below-grade construction.

Flooring

KOVARA® moisture barriers (formerly Versashield) protect more than 50 million square feet of floors worldwide. These easy-to-install products safeguard floor coverings like carpet, vinyl and ceramic tile, protecting these materials and their adhesives from staining, warping or mold caused by water and alkaline salts that migrate through concrete slabs. The results are a dramatic reduction in bumps and faults and a smooth finish.

Unlike epoxy, KOVARA® products save time and money because the installation is simple. Just roll them onto the surface, tape the seams, cut in and you're done.

In-transit Concrete Management

VERIFI® is the industry’s only in-transit concrete management system for ensuring the consistent and reliable manufacture and delivery of high-performance ready mix, from plant to pour. Qualified producers outfit their concrete trucks with VERIFI® technology, which automatically adjusts slump and temperature by adding the precise quantity of water or admixtures — in real time.

Consistent slump retention means contractors don’t have to manually add water onsite, which is a big time saver. Dependable quality means fewer rejected loads and fewer defects that require attention down the road. Plus, precise data collection and management and easy-to-read dashboards provide exceptional quality control and visibility into operations.

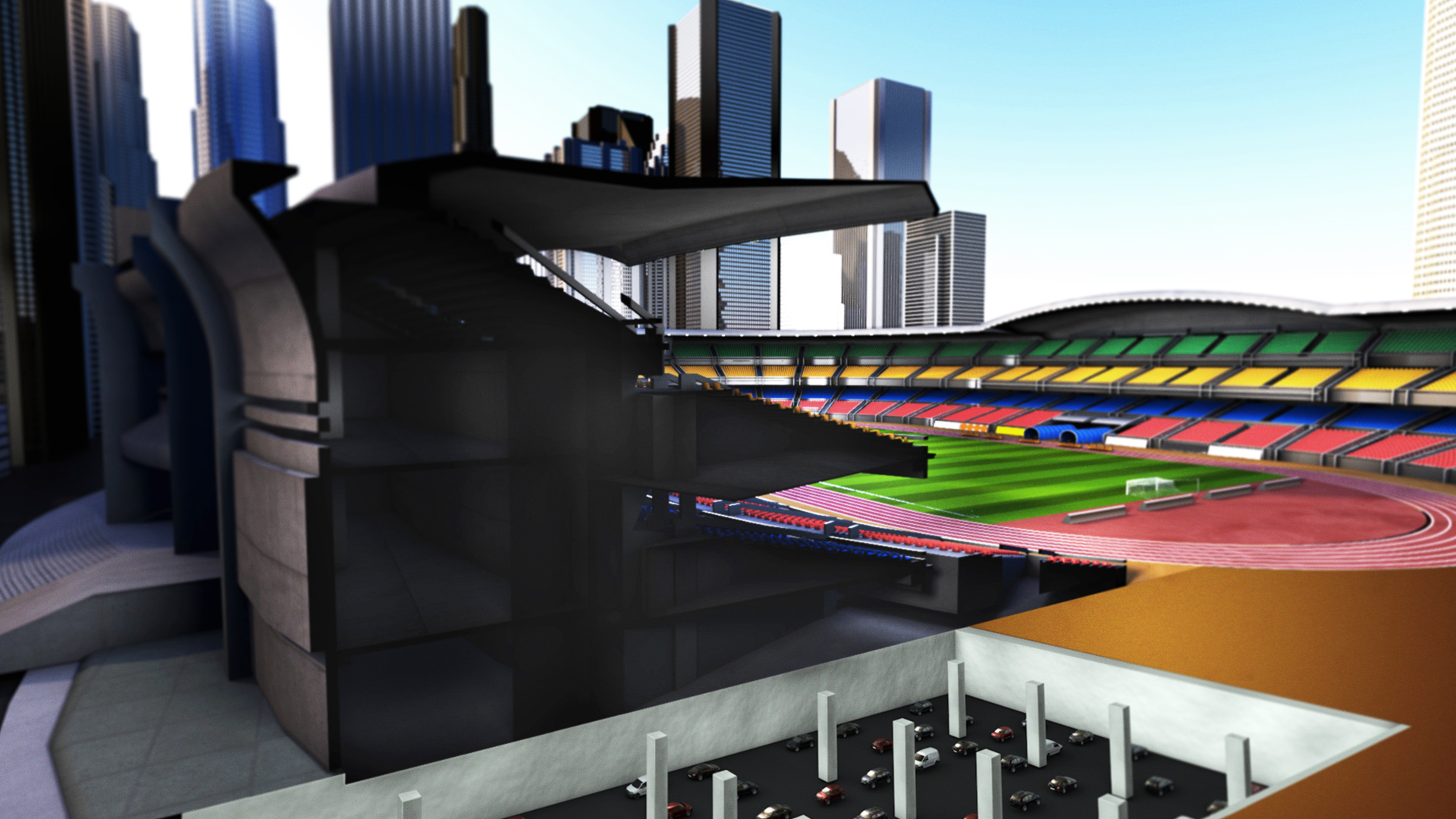

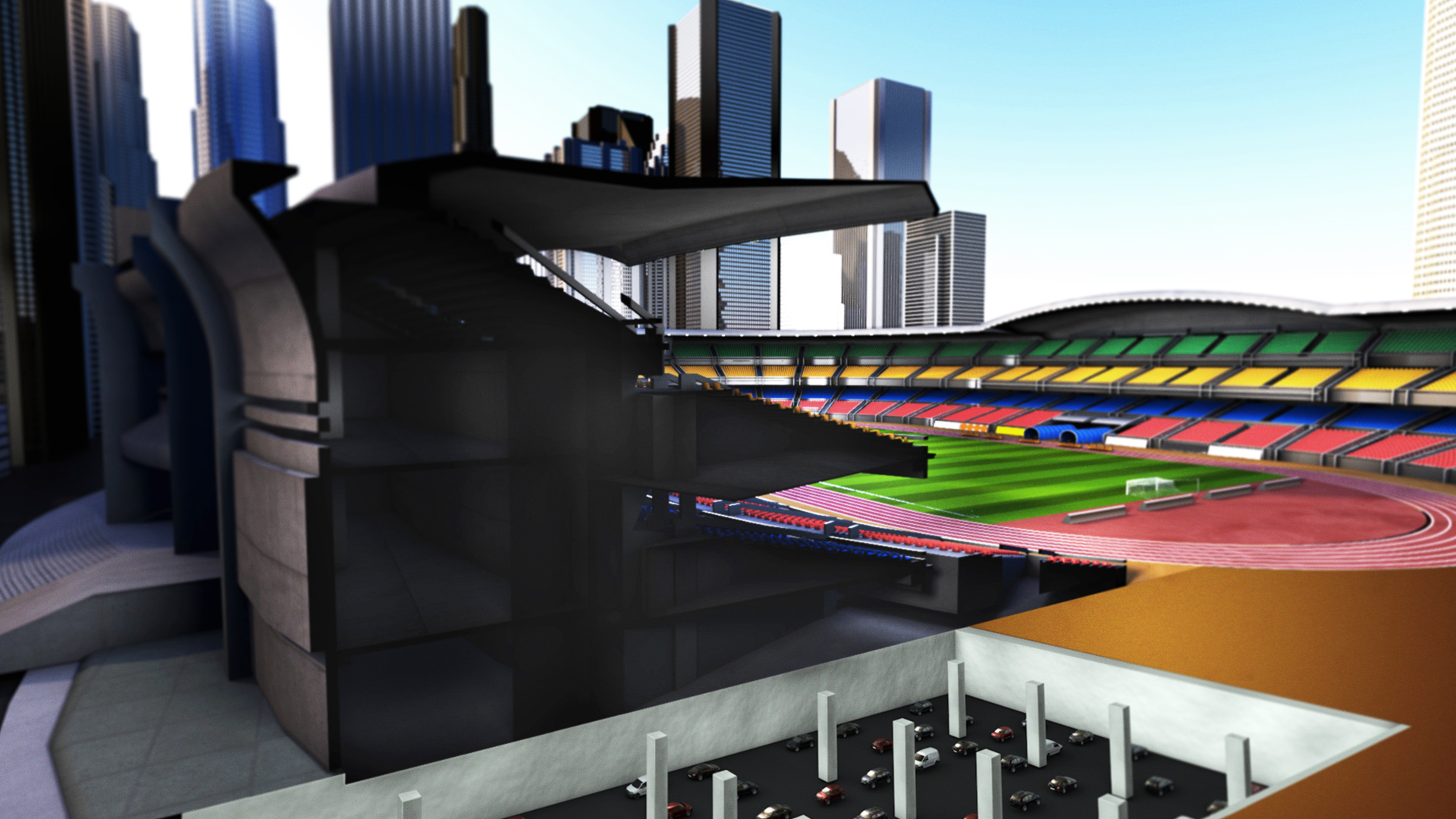

Sports Stadiums

Whether it's keeping the building dry or protecting essential infrastructure, contractors turn to us for solutions during stadium construction.

Air Barriers

To shield stadiums from damage caused by uncontrolled air and associated moisture, contractors rely on PERM-A-BARRIER® air barriers. These fully bonded membranes are NFPA 285-compliant, meeting the rigorous requirements of protecting today’s massive sports arenas. Choose from permeable or non-permeable solutions and fluid-applied or sheet-applied systems for quick, no-hassle installation. They’re engineered to perform in regional climates and compatible with commonly used building materials.

Architectural Concrete

When designing the world’s most celebrated sports stadiums, architects insist on ADVA® CAST water reducers and PIERI® specialty chemicals to create concrete components that are strong, durable and beautiful.

The ADVA® CAST line of high-range, water-reducing admixtures help make concrete with high early strength that flows through congested reinforcements and forms without segregation.

The PIERI® portfolio features appealing architectural characteristics that transform building components into enduring works of art.

Concrete

Stadiums built with concrete made with ADVA® products are as impressive to the eye as they are strong, durable and functional. ADVA® high-range water reducers and superplasticizers enable concrete producers to precisely control the physical properties of every batch. The results are superior water reduction and compressive strength for ready mix, precast and pre-stressed concrete. ADVA® products also optimize slump retention for exceptional workability.

Waterproofing - STADIUM

SILCOR® liquid waterproofing solutions and PREPRUFE® pre-applied waterproofing membranes protect your stadium from the harshest elements. They are easy to install with minimal downtime.

SILCOR® products conform to nearly every surface, and don’t require heating with unwieldy kettles, propane stoves or open flames.

Likewise, PREPRUFE® membranes form a tough, permanent and aggressive bond with any concrete slab. Independent testing shows that PREPRUFE® membranes resist lateral water migration at extremely high pressure.

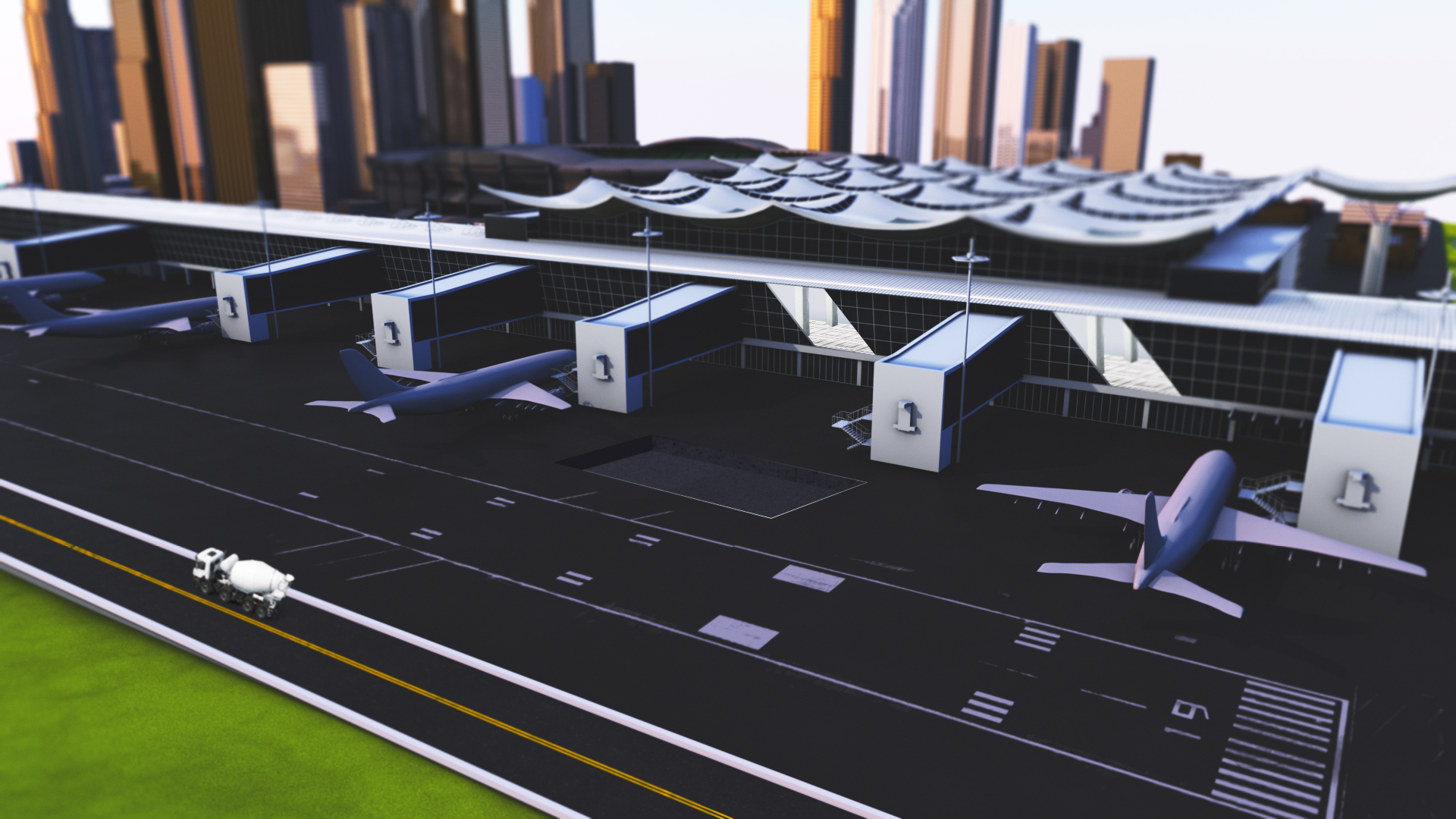

Airports

Fire protection, concrete and waterproofing are as important to airport construction as runways, terminals, and radars. We furnish multiple solutions for airport construction projects.

Fireproofing

For more than half a century, engineers have specified MONOKOTE® fireproofing to safeguard people and critical structures at major airports worldwide. MONOKOTE® Z-106/G and Z-106/HY materials are formulated specifically to provide exceptional fireproofing of structural steel members in every type of airport building. These products lower the rate of rising temperatures in steel to prolong structural integrity, providing more time to save the building from costly damage.

Concrete

GCP’s full range of concrete admixtures and macro fibers enable producers to tailor high-performance ready mix batches for every concrete application, from landing strips and taxiways to garages and terminals.

ZYLA® admixtures increase concrete’s workability and durability while STRUX® synthetic macro fibers add impact and fatigue resistance to concrete and provide superior post-crack control performance. In addition, ECLIPSE® liquid admixtures dramatically reduce drying shrinkage and cracking and curling in full or partially restrained concrete flooring and paving.

In-transit Concrete Management

VERIFI® is the industry’s only in-transit concrete management system for ensuring the consistent and reliable manufacture and delivery of high-performance ready mix, from plant to pour. Qualified producers outfit their concrete trucks with VERIFI® technology, which automatically adjusts slump and temperature by adding the precise quantity of water or admixtures — in real time.

Consistent slump retention means contractors don’t have to manually add water onsite, which is a big time saver. Dependable quality means fewer rejected loads and fewer defects that require attention down the road. Plus, precise data collection and management provide exceptional quality control and visibility into operations.

Flooring

KOVARA® moisture barriers (formerly Versashield) protect more than 50 million square feet of floors worldwide. These easy-to-install products safeguard floor coverings like carpet, vinyl and ceramic tile, protecting these materials and their adhesives from staining, warping or mold caused by water and alkaline salts that migrate through concrete slabs. The results are a dramatic reduction in bumps and faults and a smooth finish.

Unlike epoxy, KOVARA® products save time and money because the installation is simple. Just roll them onto the surface, tape the seams, cut in and you're done.

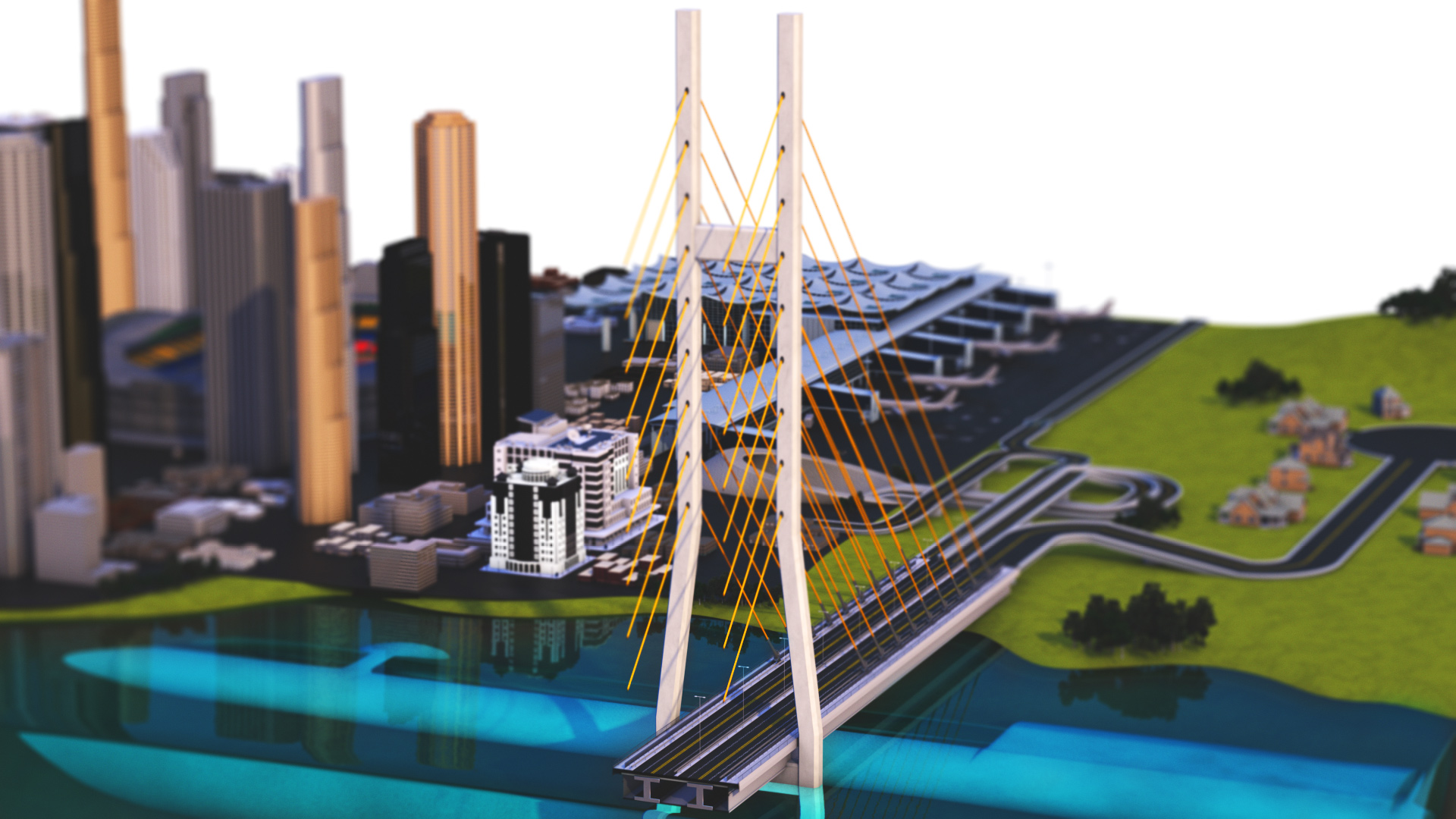

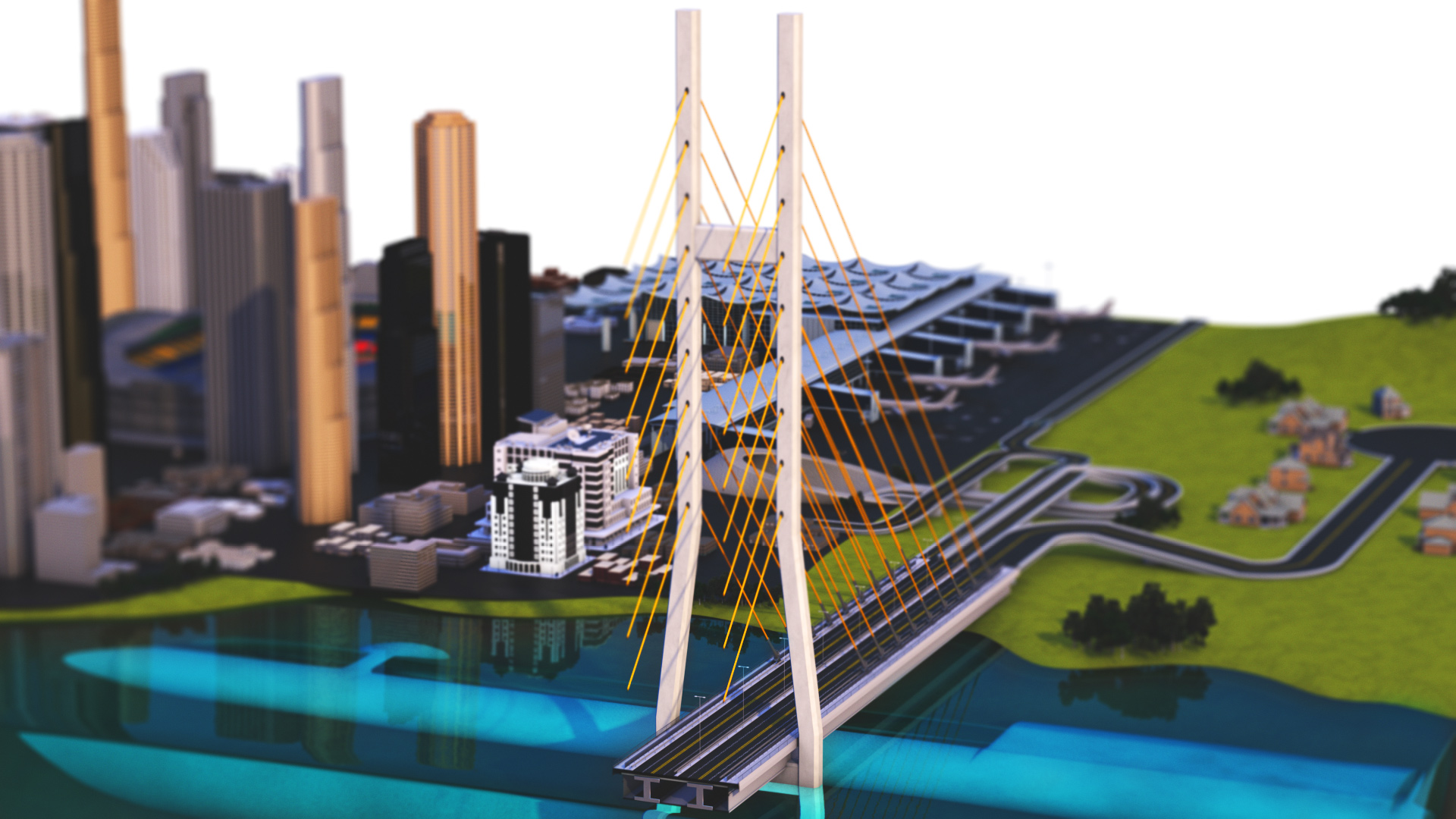

Bridges

We offer innovative, sustainable concrete structural solutions to help engineers and contractors around the world build better, stronger, sustainable bridges.

Cementitious Grout

BETEC® grouts and mortars are used by contractors to underfill and connect structural elements, such as bridge bearings, beds and joints. Formulated for every application height and for year-round use, BETEC® products are known for their stable application, ease of installation and high flowability. These qualities enable producers to avoid adapting water ratios during application, which is a huge time saver.

Concrete Technology

V-MAR® admixtures produce high-performance concrete for bridge pilings and above-waterline structural elements exposed to driving rain, snow and sleet. They improve the ease and speed of forming and placing concrete for a variety of applications. The V-MAR® product family improves the segregation resistance of self-consolidating concrete, reducing washout during underwater concrete placement.

Corrosion Inhibitor

Corrosion of reinforcing steel, typically caused by chlorides used in deicing salts or airborne from nearby saltwater sources, can cause major deterioration of reinforced concrete structures that are exposed to them. This also reduces their overall service life. Since 1978, precasters have used DCI® corrosion inhibitor to provide protection from chloride-induced corrosion. DCI is added to the concrete during mixing to increase the service of structures, while reducing life cycle costs.

Waterproofing

ELIMINATOR® liquid waterproofing is a cold-applied waterproofing membrane that protects some of the world’s most notable bridges from water, chloride, and atmospheric gases. The product combines rapid application with performance that outlasts the life of the structure. It has been installed on bridges in more than 50 countries over the past 35 years, with more than 20 million square meters of surface area protected. Developed by Stirling Lloyd nearly 40 years ago, ELIMINATOR® liquid waterproofing has a proven track record across all climates and continents. It is the waterproofing solution of choice for the Tappan Zee Bridge, the Hong Kong-Zhuhai-Macau Bridge, London’s Tower Bridge, and many others.

ELIMINATOR® liquid waterproofing can be applied quickly and cures within just an hour. And because the waterproofing is applied cold, it also reduces the risks associated with hot-applied waterproofing products.

Tunnels

We have advanced, efficient and reliable ground support solutions for some of the most complex tunnel projects, including waterproofing, fire protection, concrete and injection materials.

Shotcrete Admixture and Fiber System

Using shotcrete instead of traditional concrete can speed up construction by 30%. And when shotcrete is optimally mixed at the factory, you can significantly lower material and transport costs.

The TYTRO® shotcrete system helps shotcrete achieve faster early strength and improve bonding to rock and in between layers. Application is quick because TYTRO® products offer enhanced pumpability. In addition, shotcrete made with STRUX® fibers eliminates the need for wire mesh or mild steel reinforcement, which can add approximately 20-30% to construction costs.

Micro Fiber Technology

Producers rely on SINTA™ F microfibers and SINTA™ FDS to mix durable, high-quality concrete for their challenging underground projects. SINTA™ F fibers mechanically lock into the concrete matrix to reinforce fresh concrete, reducing plastic shrinkage, early stage cracking and permeability. Additionally, SINTA™ microfibers increase resistance to impact, abrasion, shattering and fire-spalling.

What’s more, the SINTA™ fluid delivery system contains microfibers that automate their dispensation into concrete, which boosts productivity at the plant.

Waterproofing

The PREPRUFE® shotcrete system is designed specifically for the challenges of below-grade shotcrete construction. Independent studies have shown that it resists lateral water migration at extremely high pressure (80 meter head of water).

Contractors rely on PREPRUFE® membranes because they minimize labor costs. The results: a durable, redundant waterproofing system that offers lifetime protection from water migration into and around the tunnel wall.

Fireproofing

MONOKOTE® fireproofing materials reduce the rate of rising temperatures in steel or concrete to prolong the tunnel’s structural integrity, providing up to four hours of fire resistance. These asbestos-free, life-saving products give first responders more time to evacuate people during an emergency and preserve the tunnel’s structure.

Because MONOKOTE® fireproofing materials are easy to pump and spray, application is fast and efficient, ensuring that tunnel construction stays on track and labor costs are minimized.

Leak Sealing

To protect mass transit station walls and foundations, contractors rely on the DENEEF® family of injectable grouts. Most DENEEF® products are single-component, closed-cell, hydrophobic polyurethanes, which means they’re durable and long lasting.

DENEEF® solutions can also shore up deep foundations during excavation or tunnel boring.

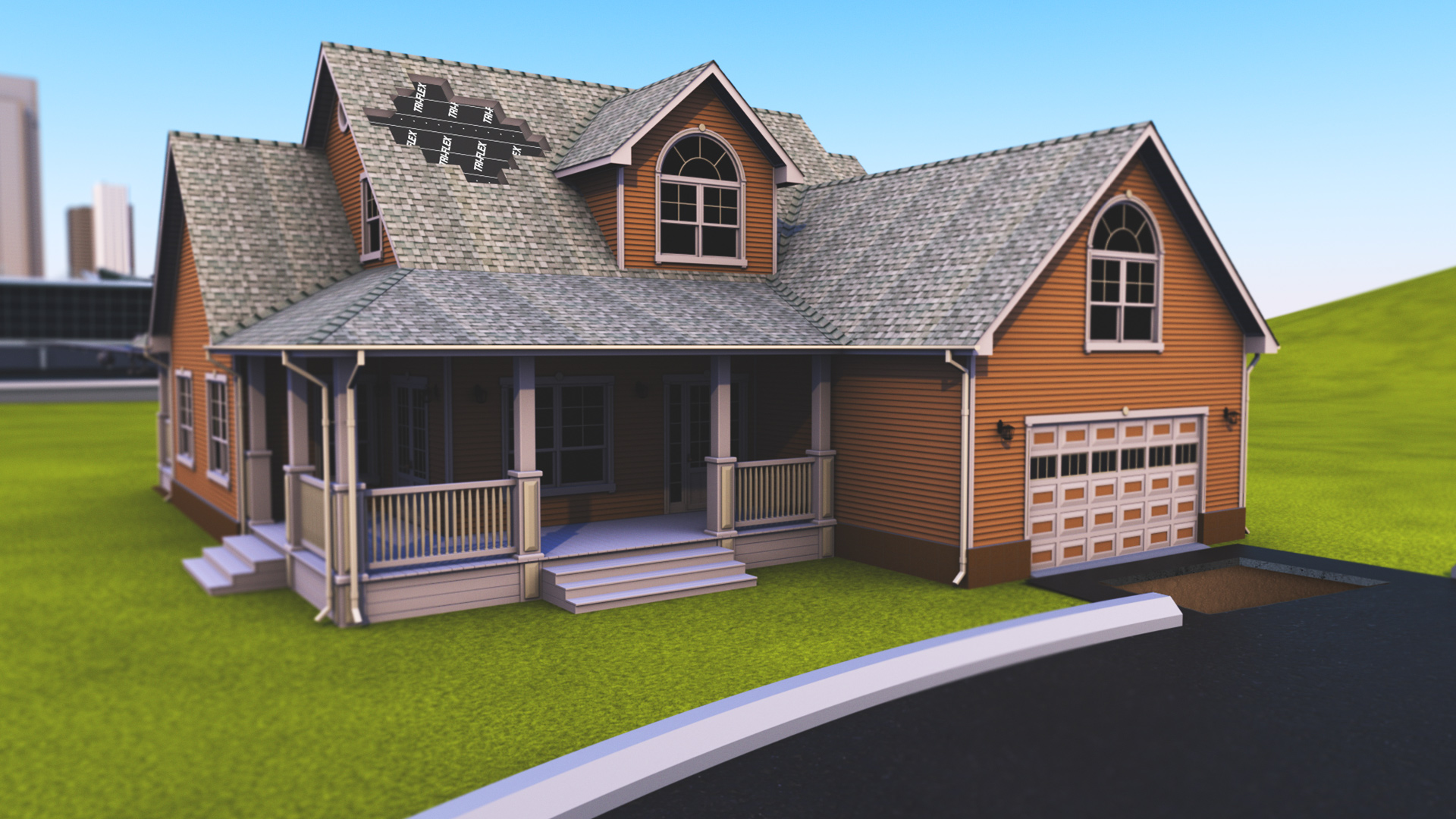

Residential Homes

Our roofing underlayment, flashing and weather barrier solutions help architects, contractors and homeowners protect homes against rain, snow, cold, heat and more.

Decorative Concrete

TOP-CAST® top surface retarders help you make eye-catching finishes for poured-in-place flatwork and precast panels, without the hassle of acid etching or sandblasting. Perfect for achieving the exposed aggregate look, TOP-CAST® products are engineered to withstand up to 150°F — as well as extreme changes in weather, temperature and humidity. These surface retarders are extremely stable and easy to apply, saving you time and money.

Roofing Underlayment

To protect homes from extreme weather conditions, roofers, builders, and architects have counted on GRACE ICE AND WATER SHIELD® roofing underlayments since 1978.

They protect homes from the harshest climates, from wind-driven rain to ice dams. The self-adhered roofing underlayment seals to the deck, seals around fasteners and seals to itself to form watertight laps. Additionally, the RIPCORD® split release on-demand technology makes it easy to protect trouble spots such as chimneys, valleys and roof-to-wall transitions.

Roof Membrane/Underlayment

TRI-FLEX® synthetic roofing underlayments are far more durable and easier to apply than felt underlayments. They’re 10x stronger than felt — and tougher, too. Their superior UV protection resists degradation and can be exposed to the elements for up to six months. Additionally, TRI-FLEX® underlayments are designed to withstand all kinds of punishment at the job site. A roll of TRI-FLEX covers 10 times the area as a roll of felt. Fewer trips up the ladder translate to less labor and lower installation costs.

Air and Water Barriers

VYCOR® weather barriers provides superior long-term protection, indoor comfort and energy efficiency — and make installation hassle free. The system’s durability means fewer callbacks.

Oak Ridge National Labs found that VYCOR® enV-S™ weather resistive barriers have an air leakage rate seven times lower than conventional house wrap. That means lower energy bills, whether the location is blistering hot or bitterly cold.

High-performance flashing - Self-adhering flashing tape

VYCOR® flashing tapes prevent the migration of water and air through windows and door openings. They offer maximum protection against water infiltration in all critical non-roof detail areas. Unmatched by traditional building papers, felts, housewraps and other flashing products, VYCOR® flashing is comprised of durable, tear and puncture resistant film, paired with an aggressive adhesive that ensures a strong bond between the flashing and the substrate.