All modern concrete is made from a combination of cement, water, coarse aggregates, fine aggregates, air, and in some cases, supplementary cementitious materials (such as silica fume, fly ash, or slag) and chemical admixtures. Each of these ingredients confer different physical properties to the concrete that affect its strength, viscosity, set time, durability, and more.

Concrete mix design is the science of choosing the types of ingredients, and the proportions to use them in, to create concrete that meets the technical specifications for a given construction project. The needed properties vary depending on the project. Flatwork, underground pipes, bridges, walls - they all require concrete with different properties. That's why concrete mix design is so important.

However, the ability to create a concrete mix design that not only meets the specifications of a project, but does so cost-effectively and in an environmentally friendly way, comes mainly from experience. GCP Applied Technologies has over 80 years of expertise in the building materials industry and decades of success in creating concrete mix designs for a variety of applications.

In the sections below, you’ll find our technical bulletins on best practices for various concrete mix designs, as well as explanations of how different types of admixtures are used when designing concrete mixes. Also included are detailed instructions for incorporating high-performance admixtures as submittals for construction projects.

Index

Air entrainment concrete mix designs

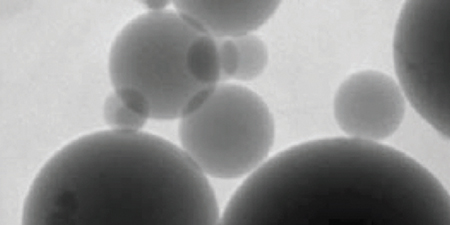

Air-entraining admixtures increase the amount of air within the concrete. Entrapped air can increase concrete durability in freezing climates because it allows water in the concrete to expand when it freezes – reducing the internal pressure caused by ice formation.

TB-0200 – Factors affecting air entrainment

Of all the enhancements we can make to concrete through the proper use of admixtures, entrainment of air is the most difficult. The reason for this lies in the many factors that influence the amount of air that can be entrained by a given quantity of an air-entraining concrete admixture. Some of these factors and their effects are summarized… more

TB-0203 – Effect of high air-entrainment agent (AEA) dosage on compressive strength

When it's necessary to increase the addition rate of AEA to compensate for one or more inhibiting influences, questions are often raised regarding the chemical influence of the concrete admixture on the strength of the concrete… more

Clay mitigation concrete mix designs

Water-reducing admixtures limit the damaging effects of swellable clays and permit the use of polycarboxylate-based admixtures, while maintaining the many benefits that polycarboxylate-based admixtures bring to concrete mix designs.

TB-1601 – Utilizing a mid-range water reducer specifically designed for clay mitigation

Clay bearing fine aggregates, commonly found in the southwest region of the United States, can adversely affect the overall performance of primarily polcarboxylate (PC) based concrete admixtures. Many clay minerals expand in the presence of water and can intercalate and absorb the polyalkylenes oxide component of PC-based admixtures, thereby reducing cement dispersion and water reduction capabilities. This has recently become a more wide spread issue because several concrete industry trends have resulted in a decreased availability of high quality natural sands with growing dependence on typically higher clay content manufactured sands… more

Control flow concrete mix designs

Control flow concrete has a slump between that of conventional concrete and self-consolidating concrete. Concrete producers and contractors get more value out of conventionally proportioned control flow concrete by reducing placing time and labor costs.

TB-1701 – Rheology-modifying high-range water reducer (HRWR) for the production of control flow concrete

This technical bulletin details a rheology-modifying PC-based ASTM C494 Type A and F high-range water reducer (HRWR) that enables the production of Control Flow Concrete, a highly flowable concrete with minimal or no segregation using unmodified conventional mix designs… more

TB-1703 – Leveraging an ASTM C494 Type A water reducer for the production of control flow concrete

Control Flow Concretes typically have slump flow values in the 16-25" (406 to 635 mm) range and may require minimal external energy to properly consolidate… more

Controlled low-strength material (CLSM) concrete mix designs

CLSM concrete is highly flowable, volume stable, and excavatable in the future – making it useful for underground pipes and backfill.

TB-1100 – Recommendations for dispensing CLSM

The CLSM mixture should have a 0 to 25 mm (0 to 1 in.) slump prior to the addition. If there is difficulty in discharging zero inch slump mixes from central mixers, try a moderate addition of a concrete air-entraining agent… more

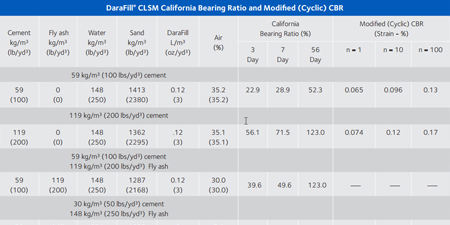

TB-1104 – CLSM test methods and results

This technical bulletin describes the test methods and results used to determine several mechanical properties of controlled low-strength material (CLSM). The information included here allows engineers to properly design with CLSM… more

Corrosion resistant concrete mix designs

Corrosion inhibiting admixtures chemically mitigate the corrosive action of chlorides (often found in water) on reinforcing steel and prestressed strands in concrete.

TB-0900—TB-911 – Guidelines for incorporating corrosion inhibitors into mix designs

From proper proportioning of concrete admixture, to offsetting the corrosive effect of chlorides in concrete, to the admixture's general properties and benefits, to combining with microsilica for protection in steel-embedded concrete, this series provides comprehensive instruction, complete with example mix designs.

High-range water reducers (HRWR)

In addition to providing excellent water reduction in concrete mix designs, HRWR admixtures generate higher compressive strengths, better slump retention, improved rheology, enhanced air control, and superior finishability.

TB-HRWR – High-range water reducer applications for a variety of mix designs

This technical bulletin series details the use of superplasticizers (or high-range water reducers) in a variety of applications. Topics include use in pervious concrete mixes, ready-mix projects where improved slump retention is desired due to hot ambient conditions, long haul times or tight slump specifications. This series also addresses HRWR incorporation in conventional and self-consolidating concrete (SCC) applications, as well as precast/pre-stress concrete (PC/PS) environments… more

TB-0110 – Admixture dispenser discharge line location and sequencing for concrete batching operations

Cement hydration is a complex chemical reaction that begins when water is added to the concrete mix. Adding chemical admixtures to the concrete mix alters this chemical reaction in subtle and sometimes complex ways. Concrete admixtures can affect cement hydration depending upon either the discharge location in the batch plant, or the point in time in the batch cycle (sequencing) at which they are discharged… more

Hydration stabilizers

Adding hydration stabilizers to a concrete mix design allows you to control the set time for concrete so it says wet and workable over the course of a large project, after a long time in transit route, or when used in hot and dry conditions.

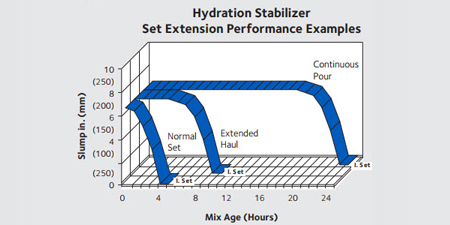

TB-1301 – Hydration stabilizer applications and performance review

Hydration stabilizers are advanced set retarders. While conventional set retarders enjoy widespread use to slow concrete set times, on many projects additional set control is needed. Hydration stabilizers are formulated to provide this extended control, ranging from a few hours of delayed set for long haul or delayed placement situations, to over 30 hours for large continuous pour projects… more

Macro synthetic fiber reinforced concrete mix designs

Synthetic macro-fibers are intended to replace welded wire mesh (WWM) as a unique form of high-strength, high-modulus synthetic reinforcement that is evenly distributed throughout the concrete matrix. Adding macro-fibers to your concrete mix design can improve impact resistance, durability and long-term crack control properties - with significantly less time and labor costs compared to WWM.

TB-1200 – Recommended mix designs, dispensing, mixing, placing and finishing

Macro synthetic fibers are long high-strength and high-modulus synthetic macro reinforcement that provide toughness, impact and fatigue resistance to concrete… more

TB-1201 – Dosage rates for light use loading applications

Macro synthetic fibers are used to replace welded-wire fabric in many slab-on-grade applications, including parking areas, flatwork and flooring. Engineers can view and compare various scenarios of slab thickness vs. fiber dosage rate options, and with local costs, select the most applicable design. However there are several applications that can be designed where one dosage rate would work… more

Rheology modifiers

Rheology modifying admixtures increase the viscosity of the concrete while still allowing it to flow without segregation. Concrete mix designs that incorporate rheology modifiers can be used to reduce the required pressure when pumping concrete and for underwater, anti-washout applications.

TB-1401 – Using rheology modifying admixtures to place underwater concrete

The successful placement of concrete underwater is dependent on a number of factors including having a suitable concrete mix. A highly flowable, low water to cement ratio concrete, manufactured with relatively high amounts of fine sand is usually a minimum requirement. Additional recommendations for underwater concrete mix proportioning and placement can be found in ACI 304R (Guide for Measuring, Mixing, Transporting, and Placing Concrete) and ACI 546.2R (Guide to Underwater Repair of Concrete)… more

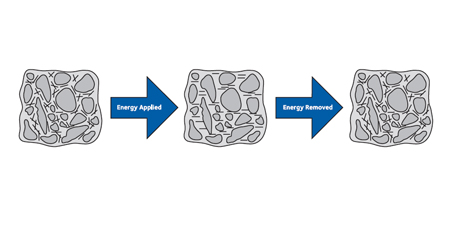

TB-1402 – Using rheology modifying admixtures to reduce concrete pump pressure

Rheology modifiers have a unique polymeric structure that, under the influence of energy (e.g. vibration or pumping), align themselves and allow coarse angular sand to flow similarly to naturally-rounded sand. At this point the polymers slide over each other in the direction of flow and reduce the yield stress of the concrete, essentially lubricating the pump hose, reducing internal friction, and reducing the pressure necessary to pump the concrete… more

Set accelerators

Concrete mix designs that include set accelerating admixtures will have a shorter setting time and increased early strength development. Both are useful properties for cold weather concreting when the rate of cement hydration decreases with lower temperatures.

TB-0801 – Cold-temperature performance of non-chloride accelerator

This technical bulletin summarizes the laboratory performance over a range of different mix designs, cement compositions and temperature exposure conditions of an ASTM C494, Type C, non-chloride, noncorrosive accelerator specifically formulated to work in concrete over a wide variety of temperature conditions… more

TB-0802 – Non-corrosive properties of a non-chloride accelerator

This technical bulletin describes tests performed on concrete containing a set accelerator to determine its effect on corrosion of embedded metals. The test procedures include cyclic polarization and potentiostatic polarization methods using mortar cylinder with embedded steel. Each test was performed with and without admixed chlorides in order to simulate both non-chloride environments and marine and deicing salt environments… more

Shrinkage reducers

Shrinkage reducers are concrete admixtures which improve durability by reducing drying shrinkage and the potential for drying shrinkage-induced cracking and curling

TB-1000 – Shrinkage reducing admixture testing, performance

This technical bulletin outlines recommended shrinkage testing mix matrices, reviews pertinent sections of ASTM C157, “Standard Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete,” and details a suggested format for reporting laboratory shrinkage test results… more

TB-1001 – Low shrinkage mix design optimization guidelines

This technical bulletin details a liquid concrete admixture specifically formulated for reducing the drying shrinkage properties of non air-entrained concrete. The article addresses mix design optimization recommendations which will enhance the potential of eliminating or dramatically reducing drying shrinkage cracking in slab-on-grade construction… more

Supplementary cementitious materials (SCMs)

In concrete mix design, SCMs are used to replace a portion of the cement to make the concrete more cost-effective and environmentally-friendly to produce. Depending on the SCMs used, the concrete may also gain other properties like slower set time or higher strength.

TB-0102 – Ground granulated blast-furnace slag (GGBFS): Its chemistry and use with admixture

There are two main advantages of incorporating ground-granulated blast-furnace slag (GGBFS) as a separate SCM into concrete mix design: (1) Each material can be ground to its own optimum fineness; (2) The proportions can be adjusted to suit the particular project needs. Since GGBFS is almost 100% glassy, it's generally more reactive than the most fly ashes. Substitutions of cement by GGBFS have been reported as high as 65%… more

TB-0704 – Calculating concrete mix proportions for dry-densified silica fume

This technical bulletin describes the steps required to adjust concrete mix proportions to accommodate the addition of dry-densified silica fume… more

TB-0708 – Shrinkage characteristics of silica fume

Concrete with silica fume is typically used in applications where cracking may be a major concern. These include environments that are highly corrosive, chemically saturated, or very abrasive and where less permeable, more durable concrete is required. For these applications concrete needs to be designed and constructed to produce the least amount of cracking… more

Tags

- ADVA

- ADVA Cast

- Airports

- Architects

- Arts & education

- Bridges

- CLARENA

- CONCERA

- Canal

- Commercial buildings

- Concrete

- Consultant

- Contractor

- DARACCEL

- DARACEM

- DARAFILL

- DARAPEL

- DARASET

- DARATARD

- DARAVAIR

- DARAWELD

- DCI

- Design Advantage

- ECLIPSE

- Energy efficient solutions

- Energy facilities

- Engineer

- FORCE

- Field support

- Functional Admixtures

- Industrial facilities

- Infrastructure

- Low Temperature

- MIRA

- Mass transit

- Mining

- Museums

- PIERI

- Paving

- Precast

- Precast producer

- Producer

- RASIR

- RECOVER

- REINFORCEMENT

- Ready Mix/Precast

- Repair and Renovation

- Residential buildings

- Retail buildings

- STRUX

- Schools

- Sports stadiums

- Structural Solutions

- Subcontractor

- Sustainability

- Technical service

- Training

- Transportation Infrastructure

- Tunneling

- Underground Solutions

- V-MAR

- VERIFI

- WRDA

- Water Reducers

- ZYLA