/ concrete / mix design

Introduction

This bulletin discusses the performance of RECOVER® hydration stabilizer for set and temperature control applications in concrete or mortar mixes. Project examples are also provided. RECOVER® complies with ASTM C494 as a Type D retarder.

Project Applications & Benefits

- Permits long hauls to remote sites

- Allows for extended truck discharge times

- Reduces need for portable batch plants or on-site cement addition

- Controls temperature increase

- Provides predictable extended set for continuous placement on mass concrete and tremie projects

What is a Hydration Stabilizer?

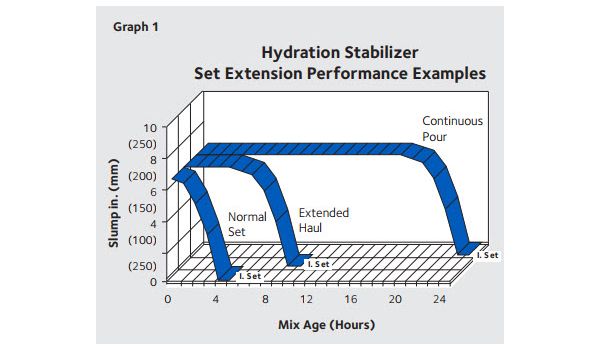

Hydration stabilizers are advanced set retarders. While conventional set retarders enjoy widespread use to slow concrete set times, on many projects additional set control is needed. Hydration stabilizers are formulated to provide this extended control, ranging from a few hours of delayed set for long haul or delayed placement situations, to over 30 hours for large continuous pour projects.

With RECOVER® hydration stabilizer, the window of plasticity can be extended in a predictable manner to bring new flexibility and opportunity to a variety of projects.

How Does RECOVER® Work?

Organic chelating agents within the formulation seek and coat the hydrating cement grains. Water and ions needed for further hydration are blocked to completely suppress cement surface activity. With the hydration reaction suspended, set is postponed and the mix retains slump, plasticity, air content, and stable temperature for the duration of the set extension. Eventually the stabilizer is chemically consumed, (the total set delay is a function of the dosage rate), normal hydration activity resumes and the mixture sets with superior ultimate strength performance.

The primary difference between hydration stabilizers and conventional retarders is the range of control over the variety of hydration reactions at the surface of the cement grain.

Conventional Retarders

Conventional retarders act on some of the hydration reactions to provide moderate slump retention and set delay. When used at high dosage rates, set extension can be unpredictable.

Over-retardation may result.

Hydration Stabilizers

Hydration stabilizers suppress all of the major hydration events to provide complete, predictable control over the setting process. Once a dosage rate is determined for a mixture, and particular set of materials, set times show little deviation.

Increased Strength and Quality

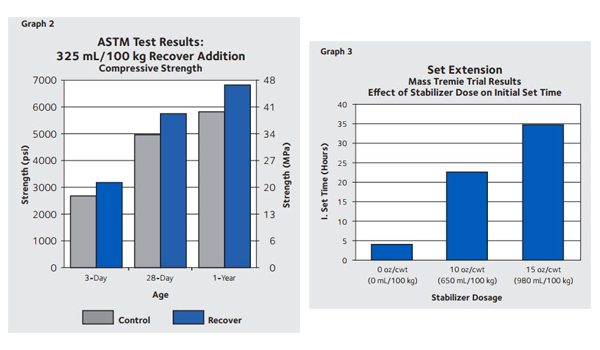

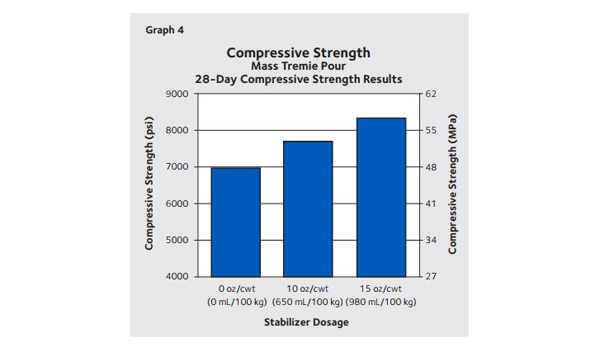

Hydration stabilizers are similar to conventional retarders with respect to the increased strength and quality that results from their use. The dispersion and set delay provided by the stabilizer produce a superior microstructure within the concrete matrix. Concrete made with RECOVER® exhibits 28 day compressive strengths that exceed similar non-RECOVER® mixes by 300 to 1,500 psi (2 to 10 MPa). ASTM test results are provided(Graph 2). A field example of this strength increase is provided in pre-job test results (Graph 4) from a Florida Power mass tremie project detailed in this bulletin.

Air Entrainment and Durability

Hydration stabilization enhances the efficiency of air entrainers by 10% to 20%. Air entrainer dosage rates may need to be scaled back proportionately. Experience shows that air stability is greatly enhanced in concrete containing RECOVER® hydration stabilizer. In most extended haul situations, excessive air loss will not occur.

Project Examples

Example 1

10,000 yd3 (7,600 m3) Extended Set Mass Tremie Concrete Placement

Florida Power needed to pour a 10,000 yd3 (7,600 m3) concrete mat, 20 ft (6 m) beneath the surface of a 90°F (32°C) body of water to serve as the base for a new cooling tower. This major mass concrete tremie placement required a concrete mix meeting the following criteria:

- Maintain plasticity and extended set for 24 to 30 hours in a 90°F (32°C) environment.

- Obtain physical properties—pumpability, slump life, and strength equal or better than normal setting concrete of the same cement factor.

The extended set was required to insure that the concrete surrounding the immersed end of the tremie line would remain plastic to allow repositioning over the 30 hour placement period.

PcCal Used For Precision Set Time Determination

The concrete supplier, Florida Mining & Materials, worked closely with GCP representatives using PcCal, a PC-based calorimetry system used by GCP to automatically monitor and determine set performance on trial mixes, with increasing RECOVER® dosage rates. The PcCal system generates precision set time information that allows increased accuracy in the final dosage selection. PcCal was also used as a quality assurance tool during the mass pour to verify set performance. Mix design and performance results are provided below:

| Cement | 564 yd3 | (335 kg/m3) |

| Fly ash | 141 yd3 | (85 kg/m3) |

| Coarse agg. | 1,456 yd3 | (865 kg/m3) |

| Sand | 1,250 yd3 | (740 kg/m3) |

| Water | 329 yd3 | (195 L/m3) |

| AEA | 5 oz/yd3 | (150 mL/m3) |

Based on the set delay information gained from pretesting (Graph 3), a RECOVER® dosage of 12 oz/100 lbs (780 mL/100 kg) of cementitious material was used in the mix to provide an average set extension of 26 hours.

Project Success

The extended set mass tremie placement was successful:

- No trucks were rejected throughout the entire job.

- Multiple samples were monitored for set time throughout the pour duration and the results showed that all mixes set between 26 and 30 hours.

- All strength tests exceeded project requirements.

Example 2

Extended Set Bedding Mortar

The Army Corps of Engineers RCC (Roller Compacted Concrete) Dam project in Washington State required extended set performance of up to 8 hours in the 2,400 yd3 (1,800 m3) of bedding mortar applied between lifts of RCC concrete.

After pretesting, a RECOVER® dosage of 15 oz/cwt (980 mL/100 kg) was selected for use in the bedding mortar mix [500 yd3 (300 kg/m3) cement, 100 yd3 (60 kg/m3) fly ash + sand + water] to provide the following hydration control benefits:

- Slumps maintained at 8 in. (200 mm) over the 7–8 hour hold period.

- Stable mortar temperatures, despite high ambient temperatures.

- Set extension allowed flexibility to use partial truckloads when needed and save remainder for use later in the day without sacrificing quality.

Example 3

Long Haul Project

In Arizona, 16,000 yd3 (12,000 m3) of concrete will be supplied for the construction of the Mead-Phoenix transmission line of the Boulder Dam Salt River Project from a location in excess of 100 miles (160 km) from the placement site. Pre-job tests show that a RECOVER® dosage of 8 oz/cwt (520 mL/100 kg) provides the additional 4 hours of set extension required for the project. Project engineers and placement crews are pleased with the RECOVER®’s ability to deliver concrete with workable slumps, stable air and controlled temperature to the remote site after a haul time in excess of 3 hours.

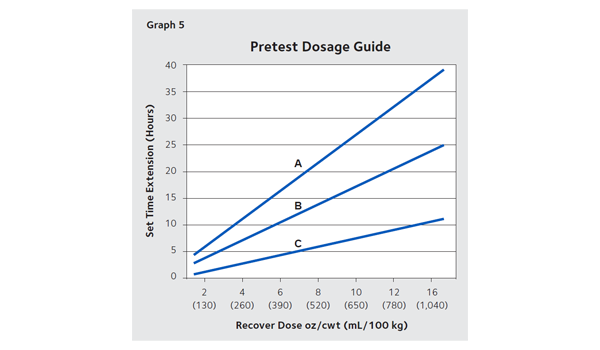

RECOVER® Dosage Selection

Most cementitious mixtures can be stabilized with RECOVER® to achieve the desired set extension. The dosage for a particular concrete mix will depend on the chemical admixtures, concrete materials and mix designs used, the concrete temperature, the quantity of concrete being treated, and the stabilization time required. Pretesting of mixes with RECOVER® is required to establish proper dosage rates. GCP sales and technical representatives are available to assist with RECOVER® dosage selections to meet the hydration stabilization needs of the project.

Graph 5 provides information to make initial dosage selections for pre-job testing. Lines A & B represent a typical dosage range for concrete mixtures in moderate temperature conditions.

Line C provides a general dosage guide for mortar mixtures and concrete used in hot weather situations.

gcpat.com | North America Customer Service: +1 (877) 423 6491

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

RECOVER® is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies Inc. All rights reserved.

.

In Canada, 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 400, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2024-06-21

https://gcpat.com/en/solutions/products/recover-hydration-stabilizer/tb-1301-recover-hydration-stabilizer-applications