/ concrete / mix design

This Technical Bulletin describes the test methods and results used to determine several mechanical properties of Controlled Low Strength Material (CLSM) containing DARAFILL®. This information will allow engineers to properly design Controlled Low Strength Material containing DARAFILL®.

Introduction

DARAFILL® is a liquid air-entraining performance additive which is added to CLSM. CLSM is also often referred to in the construction industry as flowable fill, controlled density fill, flowable mortar, and soil-cement slurry. DARAFILL® was developed by GCP Applied Technologies to broaden the potential applications and end uses for CLSM, particularly in the “high performance” spectrum of CLSM mix designs. The utilization of DARAFILL® in CLSM results in stable air contents ranging from 15-35%, allowing for approximate 50% reductions in both water contents and cementitious factors. CLSM containing DARAFILL® does not segregate, settle or bleed, resulting in a homogenous, cohesive CLSM which can be placed in one pass.

Typical unit weights for DARAFILL® CLSM range from 1400-1900 kg/m3 (90-120 lbs/ft3), lower than conventional CLSM unit weights. These lighter unit weights not only improve material yields, but more importantly, allow for ultimate strength cap specifications to be easily met for future excavatibility. DARAFILL® CLSM achieves superior flowability characteristics via the “ballbearing” effect caused by the presence of millions of air-voids, in lieu of utilizing conventional methods to obtain flowability (i.e. high water content).

As CLSM has begun to gain acceptance, some uncertainty has arisen whether to categorize and test the properties of CLSM as compacted fill or concrete. Since CLSM is generally specified in lieu of compacted fill, it seems logical to evaluate CLSM utilizing soil test procedures. Often, a combination of laboratory and field test data can provide sufficient information to the specifier to make a decision whether CLSM is a viable replacement for compacted soil for a particular end use. Depicted below are test procedure descriptions, along with test results conducted on several DARAFILL® CLSM mixes.

Table 1

Unconfined Compressive Strength (ASTM D 4832)

Unconfined compressive strength provides a useful index test to measure the strength of cohesive materials and should be considered as a valuable quality control and design tool for understanding long-term strength and durability properties of CLSM. One advantage of compressive strength testing is the simplicity and ease of fabricating and testing CLSM specimens, when compared to traditional soil test procedures.

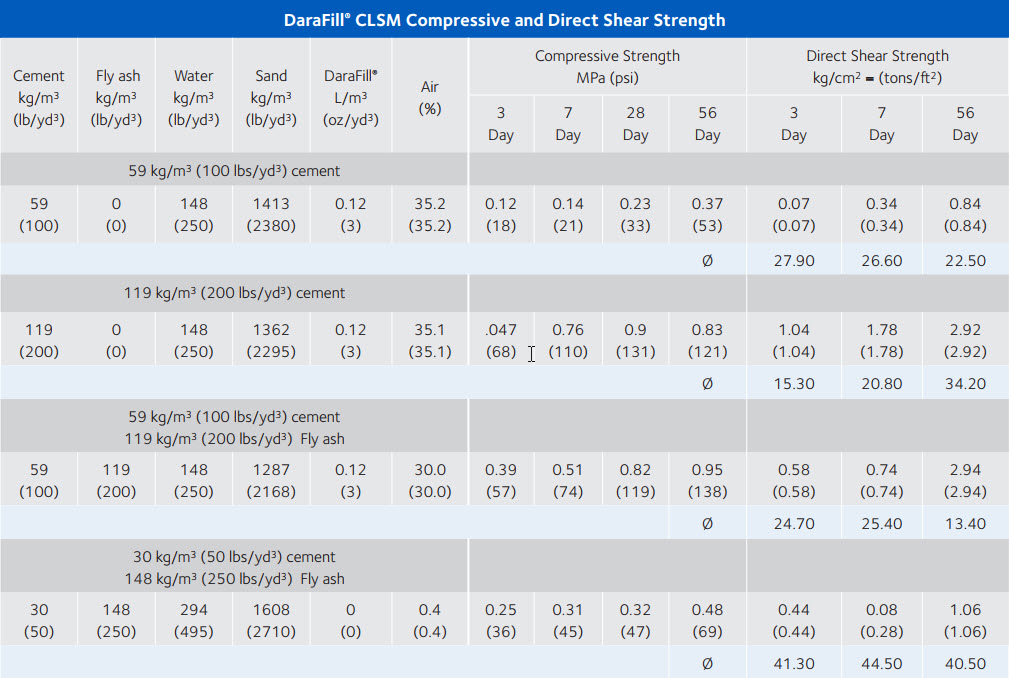

CLSM compressive strength data can provide a general indication of design parameters obtained in specific soil tests such as Direct Shear, Triaxial Shear, California Bearing Ratio (CBR), Modified (cyclic) CBR, Incremental Consolidation, Water and Air Permeability, and Freeze-Thaw Cycling etc. CLSM compressive strength data also provides assurance that CLSM mix designs do not exceed maximum strengths required for future excavation. Tables 1 and 4 depict compressive strength results conducted in accordance with ASTM Standard Test Method for Preparation and Testing of Soil-Cement Slurry Test Cylinders (ASTM D 4832) for several CLSM mixes at 3, 7, 28 and 56 days.

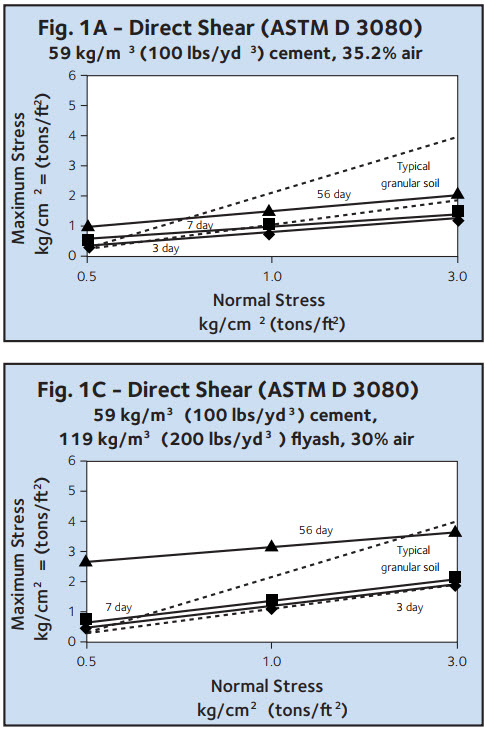

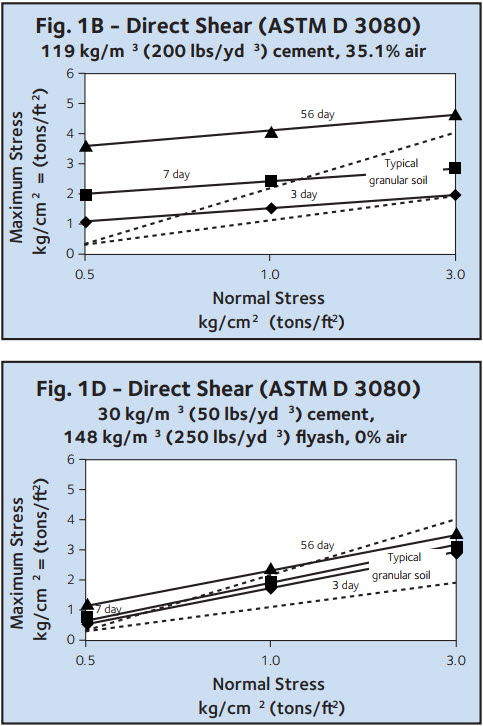

Direct Shear (ASTM D 3080)

Shear strength data measures the ability of the soil to resist shear stress. Large uncontrolled movements (i.e. landslides) occur when the shear stresses from loading exceed the shear strength of the soil. Typically, because soils exhibit a wider variety of deformation characteristics and more complex failure behavior, when compared to concrete, engineers must analyze stress fields in three dimensions. Fortunately, principles of applied mechanics are considered to be reasonably applicable for measuring properties of soils. Therefore, the Direct Shear Test (ASTM D 308), can be utilized to measure the drained shear strength for compacted soil and CLSM.

Referring to Table 1 and Figures 1A-1D, direct shear testing was conducted on three DARAFILL® CLSM and one reference CLSM mix at 3, 7 and 56 days. At 56 days, all mixes met or exceeded typical compacted granular soil shear strengths. Three and 7-day data shows all mixes performed approximately equal to typical compacted granular soil. DARAFILL® CLSM mixes utilized 59-178 kg/m3 (100-300 lbs/yd3) cementitious material, 148 kg/m3 (250 lbs/yd3) water, with air contents of 30-35% achieved through the addition of one 0.12 L/m3 (3 oz/yd3) DARAFILL® capsule. The excellent shear strength properties of DARAFILL® CLSM at low unit weights is enhanced by the cohesion properties of the cement.

Table 2

California Bearing Ratio (ASTM D 1883)

The load bearing capacity of soil and CLSM is directly related to its ability to support foundations, pavements and other structures without failing or experiencing long-term settlement. Ultimate shear resistance of soils and CLSM are largely derived from shear strength and bearing capacity factors. The California Bearing Ratio Test (ASTM D 1883), commonly know as the CBR test, is widely utilized for subbase and subgrade pavement design.

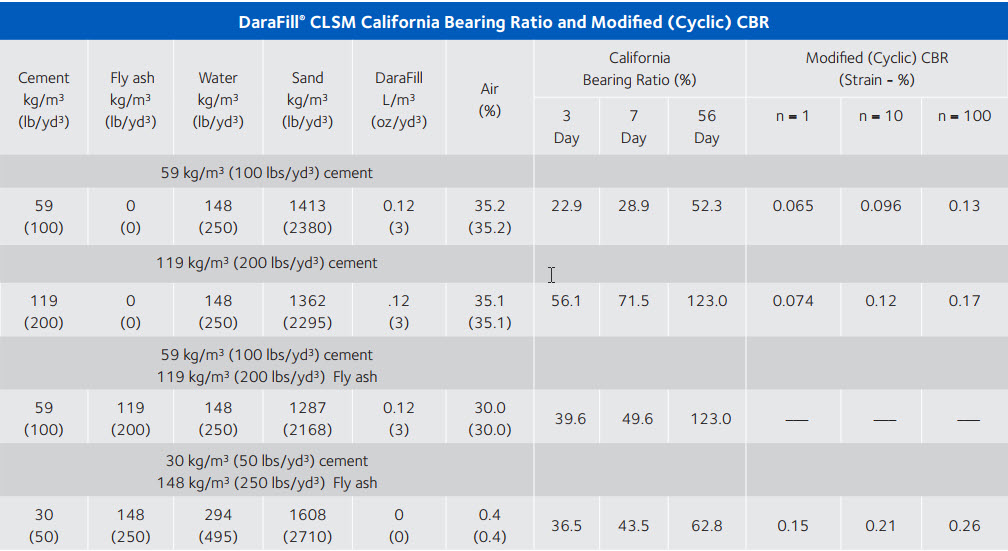

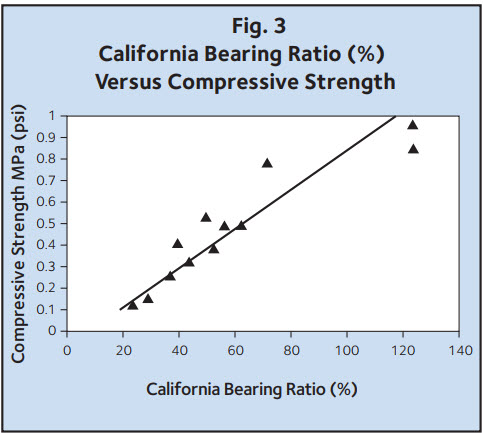

Referring to Table 2 and Fig. 2, CBR testing per ASTM D1883 was conducted on 3 DARAFILL® CLSM and 1 reference CLSM mix. The test procedure consists of measuring the force required to penetrate the surface with a 1936 mm2 (3 in.2) piston measured at 2.5 mm (0.1 in.) depth increments up to 12.7 mm (0.5 in.). The resulting load-deflection curves are then expressed as a percentage of a reference, typically standard crushed rock. CBR indexes are correlated to soil’s utilizing classification systems recognized by AASHTO and USCS.

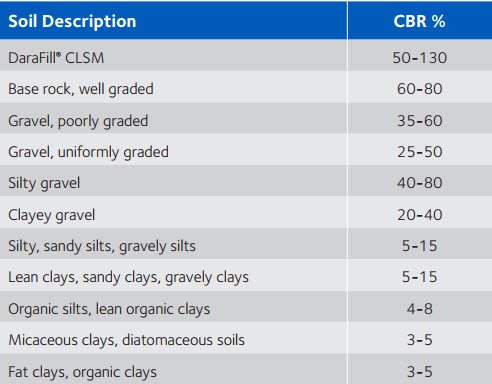

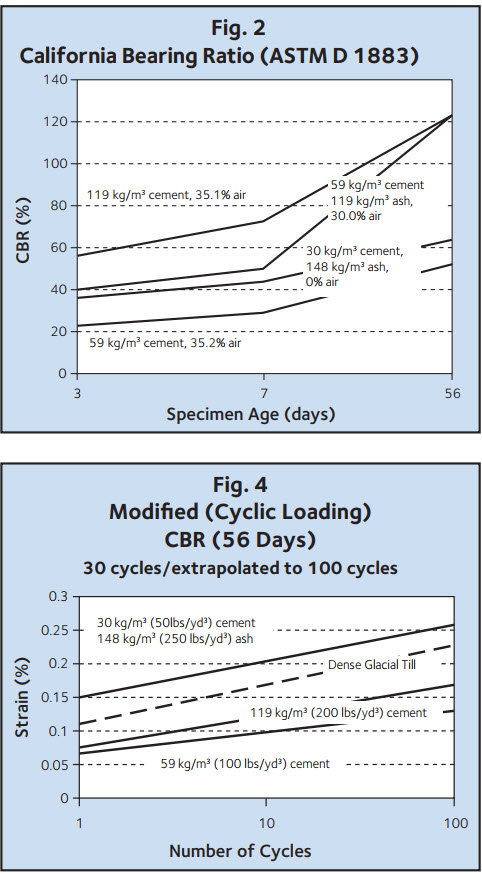

Fig. 2 shows that the three DARAFILL® CLSM mixes tested at 3, 7 and 56 days rated a minimum “very good subgrade” at early ages (3 days), while all mixes rated “good base” or better at later ages (56 days). Fig. 3 depicts CBR indexes on the X axis and compressive strength on the Y axis and reveals a strong relationship between CBR indexes and compressive strengths exists. This relationship is valuable since it allows for compressive strength specifications to help assure adequate in-place CBR properties are achieved. Table 3 depicts typical California Bearing Ratio Indexes for several categories of soils and DARAFILL® CLSM.

Modified (Cyclic Loading) CBR

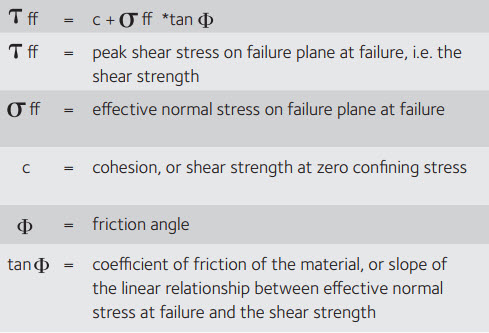

The California Bearing Ratio test was modified to compare the relative resistance of compacted fill and CLSM materials to cyclic loading. A cyclic load per unit area of 0.007-0.17 MPa (1-25 psi) was applied to test specimens for 30 cycles with data further extrapolated to 100 cycles. These loads were used since 0.007 MPa (1 psi) approximates the weight of pavement and 0.17 MPa (25 psi) is the approximate stress exerted on base coarse just below pavement by a large commercial truck wheel.

Two strain components developed during cycling: a recoverable elastic component and a plastic component, which causes deformation. The plastic deformation, or cumulative strain, increased with each cycle, but at a decreasing rate. The modified CBR test determines cumulative strain, which relates to the deformation characteristics of DARAFILL® CLSM.

Table 3

Table 2 and Fig. 4 shows results of modified CBR testing conducted on a typical compacted granular soil (dense glacial till) and two DARAFILL® CLSM and one reference CLSM mix designs. The results indicate both DARAFILL® CLSM mix designs outperformed the typical compacted granular soil and reference CLSM mix. Testing was also done on a dry sand specimen, with results showing a magnitude higher level of strain (2.3%) compared to the other mixes.

Triaxial Shear (Consolidated Drained) (USACE EM 1110-2-1906)

The most common and relevant test procedure for predicting in-place rigidity and overall strength properties of compacted fill is the triaxial shear test. Triaxial shear tests are conducted in a drained or undrained mode, depending on the water permeability properties of the fill material. Since DARAFILL® CLSM is porous and has relatively high permeability properties (similar to sand and gravel), a drained triaxial shear test procedure was utilized.

Shear strength properties of granular material are largely dependent on the effective confining stress acting on the soil element. For many granular materials, shear strength increases linearly as effective confining stresses are increased. The MohrCoulomb failure law defines this linear relationship as:

Cohesion and friction angle characteristics for granular materials are best measured by testing specimens over a range of effective confining stresses and measuring the peak shear stress, then best fitting a straight line to the data. The intercept of this straight line with the shear stress axis equals the cohesion of the material. The slope of the straight line (change in shear strength/change in normal stress) equals tan (I).

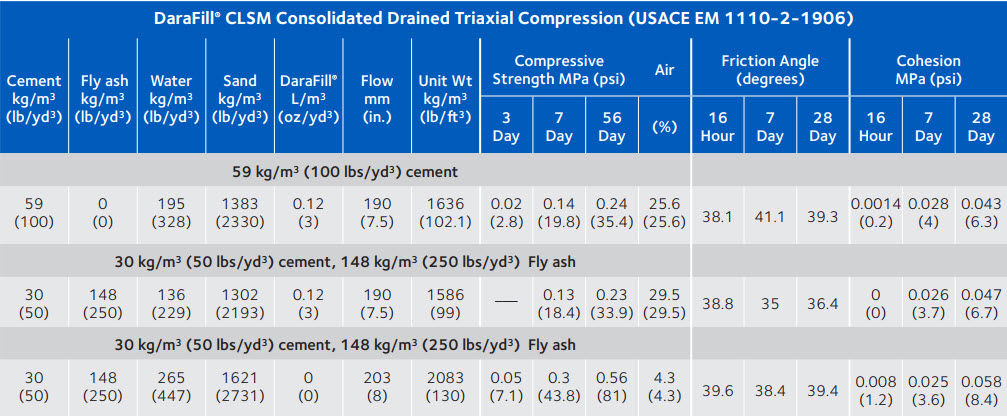

Consolidated Drained Triaxial Compression Testing (USACE EM 1110-2-1906) was conducted on two DARAFILL® CLSM mixes and one reference CLSM mix at 16 hrs, 7 days and 28 days, with 16 hour data providing guidance for determining when the hole can be topped off or backfilled. Referring to Table 4, friction angle data shows that reference and DARAFILL® CLSM mix designs at 16 hours have already developed friction angle values representative of well compacted fill. Both DARAFILL® CLSM mixes achieved minimum 38 degree friction angles at 16 hours, while typical well compacted fill achieve ultimate friction angles in the mid 30’s or higher.

Cohesion values at 16 hours are negligible for the DARAFILL® CLSM mixes, but most compacted granular fills also have negligible cohesion properties at all ages. From 16 hours to 28 days, the excellent cohesive properties of the cementitious constituents begin to develop. For example, cohesion for the 59 kg/m3 (100 lbs/yd3) DARAFILL® CLSM mix increased from 0.0014 MPa to 0.043 MPa (0.2 psi to 6.3 psi). In summary, consolidated triaxial shear strength testing indicates that all DARAFILL® CLSM mixes tested equal to or superior to granular compacted fill at 16 hours, with further gains after 16 hours as the cohesive properties of the CLSM continue to develop.

Incremental Consolidation (ASTM D 2435)

A Standard Test Method for One-Dimensional Consolidation Properties of Soil (ASTM D 2435), also commonly called the Odometer Test, is utilized to help estimate both the rate and total amount of differential and total settlement for foundations and backfill. Consolidation property values are also utilized to derive bedding factors and soil stiffness values needed for pipe bedding design.

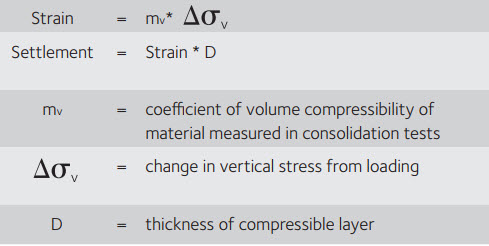

Particulate materials show a relationship between vertical strain and the change in vertical stress applied in a one-dimensional consolidation test. This relationship can be used to compute vertical strain of the material and settlement resulting from a load increment as depicted below.

gcpat.com | North America Customer Service: +1 (877) 423 6491

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 475, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2024-06-21

https://gcpat.com/en/solutions/products/force-10000-d-silica-fume/tb-1104-darafill-controlled-low-strength-material