Overview

DUCTILCRETE® engineered systems are optimized for industrial applications. These differentiated slab systems give warehouses, distribution centers, manufacturing facilities, and data centers greater flexibility in their floor space while lowering maintenance costs. In addition, DUCTILCRETE® paving solutions offer better performance and durability than conventional concrete paving.

Products & Accessories

Products

- Product Name

- Description

- Key Benefits

- Applications Type

DUCTILCRETE® CP100 is an engineered system for exterior concrete slabs and non-DOT concrete paving.

- No requirement for joint fillers

- Reduced long-term maintenance

- 3-year warranty provided by licensed contractor

- Parking lots

- Driveways

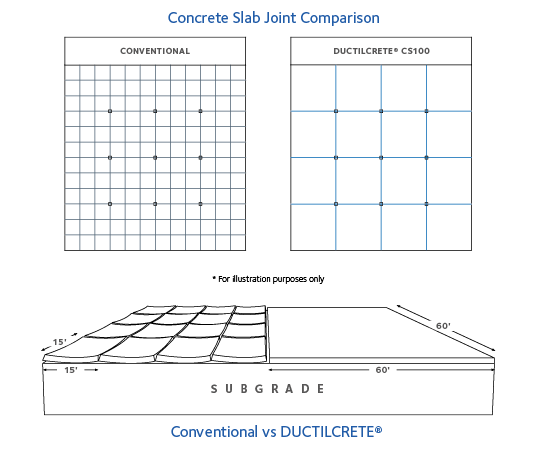

DUCTILCRETE® CS100 is a patented dual-layer engineered system for concrete slabs.

- Up to 75% contraction joint reduction

- Reduced curling

- Reduced long-term maintenance

- Warehouses

- E-commerce and distribution centers

- Manufacturing facilities

DUCTILCRETE® FS100 is an engineered system for concrete slabs.

- Up to 75% contraction joint reduction

- Reduced curling

- Reduced long-term maintenance

- Cold storages

- Freezer warehouses

- Food service and manufacturing

DUCTILCRETE® HB100 is a patented dual-layer engineered system for concrete slabs based on the Heidebed® technology and method.

- Superior slab finish without the residual effects of tilt-up construction

- Reduced curling

- Reduced long-term maintenance

- Warehouses

- E-commerce and distribution centers

- Manufacturing facilities

DUCTILCRETE® IT100 is an engineered system for refurbishment of existing interior concrete slabs.

- Up to 75% contraction joint reduction

- Superior slab finish

- Reduced curling

- Warehouses

- E-commerce and distribution centers

- Manufacturing facilities

DUCTILCRETE® WT100 is an engineered system for non-DOT concrete paving.

- No requirement for removing existing concrete or asphalt

- No requirement for joint sealers

- Reduced long-term maintenance

- Parking lots

- Driveways

More solutions

STRUX® Synthetic Macro-Fibers

Overview A replacement for welded wire mesh. Welded wire mesh has long been used to reinforce slab-on-ground concrete, bridge decks and thin-walled precast applications for...

READ MOREMIRA® Mid-Range Water Reducers

Overview Flatwork can be challenging for concrete contractors. For high-end residential and commercial construction, concrete producers need a mix that can be easy to place ...

READ MOREZYLA® Water-Reducing Admixtures

Overview Better concrete, without downsides. The products comprising the ZYLA® brand are designed to increase the workability, finishability and durability of concrete. Bet...

READ MOREFebruary 26, 2018

ASTM F710: Preparing the Concrete Floor

Why prepare the concrete slab? There are many factors that go into a successful flooring installation project, from selecting an appropriate floor material to a proper installation procedure. But jus...

READ MOREApril 03, 2018

When high-performance flooring adhesives lose the battle against alkalinity

When flooring budgets are tight, contractors often look for ways to keep installation costs down. For projects where high moisture in the concrete slab is an issue, installers may automatically turn t...

READ MOREApril 03, 2018

A bonding experience: Ensuring good concrete-to-flooring adhesion

For flooring that is adhered to a concrete slab, achieving and maintaining a secure bond is essential for long flooring life and satisfactory performance. Easier said than done. There are multiple fac...

READ MOREMay 11, 2018

Choosing flooring for retail environments

In today’s retail environments, floors aren’t just a surface to walk on…they play a key role in helping create a positive customer experience. In fact, choosing the right floor is just as important as...

READ MORE