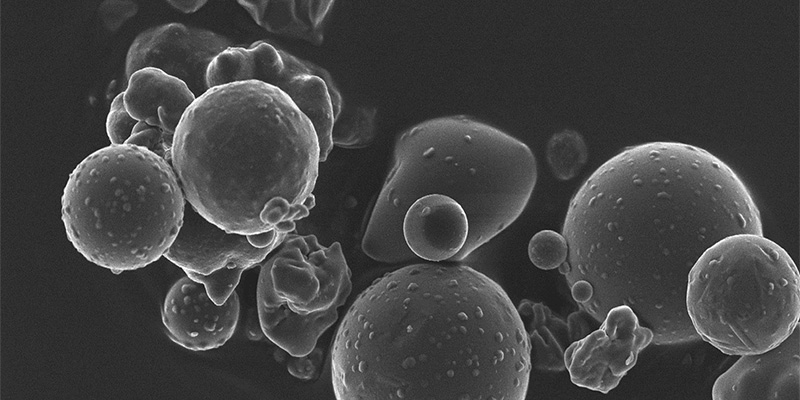

It isn’t often that you can equate coal-related products with energy efficiency, but when it comes to fly ash, it actually does help. This fine powder byproduct of coal plants is often used to replace natural materials in the production of concrete. Using fly ash reduces CO2 emissions. In fact, for every ton of cement replaced with fly ash, nearly one ton of CO2 is kept from entering the atmosphere.

Its primary benefits come from its durability and workability though. Replacing a certain percentage of Portland cement with fly ash imparts workability, allowing the concrete to be placed and finished more easily. Fly ash also reduces the internal porosity of the hydrated concrete improving its durability. This enables ready mix producers to differentiate themselves by offering contractors a product that is both durable and workable. Fly ash also typically replaces some cement at a reduced cost, helping ready-mix concrete producers to increase margins.

Contact us about control flow concrete

However, there are concerns now about fly ash shortage. Due to economical conditions, many power plants have been converted to use natural gas instead of coal in their operations. At some of the plants still burning coal, environmental concerns have led to the use of powdered activated carbon (PAC) to scrub mercury from the resultant gases before release to the atmosphere. The PAC is collected with the fly ash, and it can have a large impact on the efficacy of concrete admixtures , thus limiting its usefulness. Although good, clean fly ash is still available in some areas, trucking fly ash to regions that are seeking to use it can be cost-prohibitive.

This is spurring ready-mix producers to explore alternatives to fly ash, including slag, limestone fines, metakaolin, and silica fume. Chemical admixtures also help to enable the use of these alternate pozzolans. Ultimately, it is important to look for long-term solutions to the fly ash shortage, and to evaluate alternatives to fly ash.

Related articles

December 11, 2017

Is concrete a sustainable building material?

When we think about concrete, environmental sustainability is not always the first thing that comes to mind. But this popular building material actually provides a number of significant environmental ...

READ MOREDecember 04, 2017

Achieving high flow with reinforced concrete

Concrete producers will often add synthetic macro fibers into their concrete to improve its toughness and durability. This is much easier than physically placing welded wire mesh, which can be labor-i...

READ MOREDecember 17, 2018

How two buildings in Seattle achieved high-strength concrete

Historically, the term "high-strength concrete" (HSC) has been relative. The latest edition of "Design and Control of Concrete Mixtures" (DCCM) considers HSC to be at a "strength significantly beyond ...

READ MOREJune 01, 2018

Reduce variability with an in-transit concrete management system

One way ready-mix producers can minimize leakage—rejected loads, back charges and material inefficiencies—is through improved consistency truck to truck, reducing variability of the concrete. Further ...

READ MOREAugust 30, 2018

Ready-mix truck time optimization

A recent Concrete Producer article detailed how fictional ready-mix producer WW was able to reduce average time between driver clock-in and loading of the first truck by three minutes. This translated...

READ MORETags

- CONCERA

- Concrete