Introduction

The use of synthetic macro fibers as a replacement for welded wire mesh is becoming wide spread. It is however, important to ensure that the level of reinforcement offered by the synthetic macro fibers is in fact equivalent to that of the welded wire mesh that it is replacing.

This document has set out to address this issue and has been written in the form of a generic specification that, if adhered to, should eliminate the possibility of producing synthetic macro fiber reinforced concrete septic tanks of inferior quality to those that are reinforced with welded wire mesh.

In order to guarantee a minimum level of residual strength that is a figure-of-merit for crack width control, it is important to have confidence in the test data. The industry accepted test method for characterizing the performance of fiber reinforced concrete, ASTM C13991, is subject to high statistical variability. This high statistical variability is caused by the small cross section of the test specimen, heterogeneous fiber distribution, pre-cracking of the test specimen as well as variation in the location of the crack.

It is therefore important that careful attention be paid to the statistical validity of the test data that is used to predict the performance of the fiber reinforcement in concrete.

The number of specimens cast and tested, the average and the standard deviation are all essential elements to increase the confidence in the predicted performance of synthetic macro fiber reinforcement in concrete.

Recommended generic specification language.

Materials New Section:

1.1 Tanks produced with synthetic macro fiber reinforcement shall demonstrate compliance with all applicable standards.

1.2 Synthetic macro fibers used shall meet the requirements of ASTM C1116, Section 4.1.3, Part III2.

1.3 Structural design of septic tanks shall be by calculation or by performance. Design by calculation shall be completed using the Strength Design Method (ultimate strength theory) outlined in ACI 318-02, Chapter 93. Design by performance requires the manufacturer to demonstrate that failure will not occur by physically applying loads to the product. The load applied shall be 1.5 times the anticipated actual loads in service.

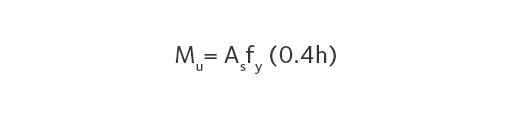

1.4 When synthetic macro fibers are used to replace steel reinforcement in septic tanks, equivalent performance must be shown based on engineering calculations. The ultimate flexural strength of the fiber reinforced wall must match that of the steel reinforced concrete wall. The ultimate flexural capacity, Mu in (in.-lb) of the steel reinforced concrete wall is given by

Where:

As = Area of steel, in.2/ft

fy = yield stress of steel, 60,000 psi

h = thickness of wall, inches

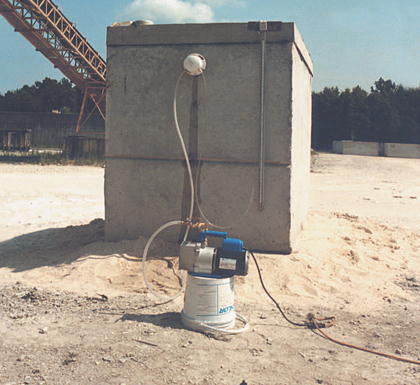

Vacuum testing of concrete septic tanks

J

J

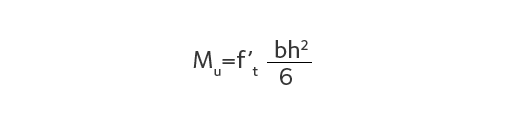

The flexural capacity, Mu in (in.-lb) of the fiber reinforced concrete wall is given by

Where:

b = unit length of wall section (12 inches)

h = thickness of wall in inches

f’t = the minimum average residual strength (psi) of the fiber reinforced concrete when tested according to ASTM C13991, and calculated as specified herein.

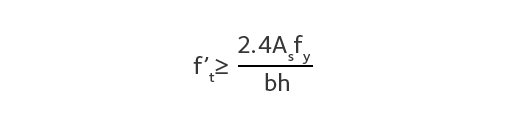

Equivalent performance between steel and synthetic macro fiber reinforcement is demonstrated if the minimum average residual strength of the synthetic macro fiber reinforced concrete f’t satisfies the following equation

Based on the above engineering analysis, the required residual strength of the synthetic macro fiber reinforced septic tank iscalculated for typical steel meshes and

presented in Table 1.

1.5 The minimum average residual strength, f’t of the concrete mix designs used to manufacture septic tanks with synthetic macro fibers shall not in any case be less than 150 psi when tested in accordance with ASTM C13991 (see Note To Specifier).

1.6 The residual strength of the concrete with synthetic macro fibers shall be determined from samples prepared from concrete mixture with a design compressive strength of 4,000 psi (or at the design concrete strength for the septic tank).

Table 1

STRUX® 90/40 Fiber Reinforcement Dosage Rate Table

| Minimum Average Residual Strength, f’t, to Match Performance of Steel Mesh | |||||||||||||

| 6 in. x 6 in. | |||||||||||||

| W1.4 | W2 | W2.9 | W4 | ||||||||||

| Gauge | 10 / 10 | 8 / 8 | 6 / 6 | 4 / 4 | |||||||||

| As (in.2/ft) | 0.028 | 0.040 | 0.058 | 0.080 | |||||||||

| Wall thickness (in.) | — | Steel Ratio | f ‘ t (psi) |

STRUX® 90/40 wf (lbs/yd3) |

Steel Ratio | f ‘ t (psi) |

STRUX® 90/40 wf (lbs/yd3) |

Steel Ratio | f ‘ t (psi) |

STRUX® 90/40 wf (lbs/yd3) |

Steel Ratio | f ‘ t (psi) |

STRUX® 90/40 wf (lbs/yd3) |

| 2.00 | — | 0.12% | 168 | 4.50 | 0.17% | 240 | 7.00 | — | — | — | — | — | — |

| 2.25 | — | 0.10% | 150 | 4.00 | 0.15% | 213 | 6.00 | 0.21% | 309 | 10.75 | — | — | — |

| 2.50 | — | 0.09% | 150 | 4.00 | 0.13% | 192 | 5.25 | 0.19% | 278 | 9.00 | — | — | — |

| 2.75 | — | 0.08% | 150 | 4.00 | 0.12% | 175 | 4.75 | 0.18% | 253 | 7.75 | — | — | — |

| 3.00 | — | 0.08% | 150 | 4.00 | 0.11% | 160 | 4.25 | 0.16% | 232 | 6.75 | 0.22% | 320 | 11.5 |

| 3.25 | — | 0.07% | 150 | 4.00 | 0.10% | 150 | 4.00 | 0.15% | 214 | 6.00 | 0.21% | 295 | 10 |

| 3.50 | — | 0.07% | 150 | 4.00 | 0.10% | 150 | 4.00 | 0.14% | 199 | 5.50 | 0.19% | 274 | 8.75 |

| 3.75 | — | 0.06% | 150 | 4.00 | 0.09% | 150 | 4.00 | 0.13% | 186 | 5.00 | 0.18% | 256 | 7.75 |

| 4.00 | — | 0.06% | 150 | 4.00 | 0.08% | 150 | 4.00 | 0.12% | 174 | 4.75 | 0.17% | 240 | 7 |

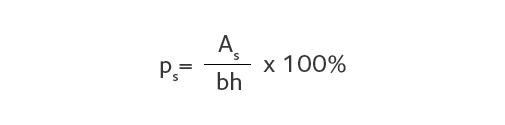

Note To Specifier: The minimum residual strength of 150 psi is equivalent in performance to that of concrete with a steel ratio, , of 0.10% based on the engineering calculation mentioned in the above Section 1.4. The steel ratio, , is given by:

Where:

As = Area of steel (in.2/ft)

h = Thickness of wall (inches)

b = Unit length of wall section (12 inches)

For steel reinforcement not shown in Table 1, calculate the minimum average residual strength (f’t) as specified in Section 1.4.

This steel ratio is the minimum steel ratio of 0.10% recommended by ACI-318-02, Chapter 16, Section 16.4.24, for precast nonprestressed walls.

The number of specimens tested to determine the residual strength, shall not be less than eight (8).

The average residual strength factor (ARS) of each single test shall be reported.

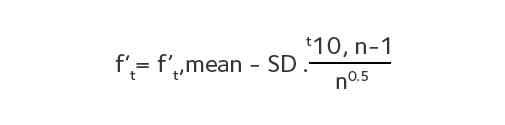

The minimum average residual strength, f’t, shall be derived as follows:

Where:

f’t, mean = mean value of the average residual strength, ARS, for all test specimens

SD = Standard Deviation of the ARS results of all tests

t10, n-1 = Student t distribution at 10% probability for n-1 specimens (see Table 2)

n = number of specimens tested

1.7 The tests shall be conducted by an independent certified laboratory or be witnessed by an independent certified consultant.

1.8 Mix designs showing compliance to ARS (average residual strength factor) will not need to be re-tested unless there is a change to the mix design properties or proportions and/or materials used from that of the pre-qualified mix.

1.9 The fiber content of concrete can be determined from either hardened or fresh concrete samples.

1.9.1 Hardened Concrete

Three test cores (at least 3 in. x 6 in. in size) shall be taken from hardened concrete according to ASTM C425. The volume (Vc) of the cores shall be determined by calculation.

The concrete cores shall be crushed in a compression testing machine, or other suitable device, so that all the fibers in each core can be separated from the concrete. The fibers from each core shall be cleaned and then weighed (mf) to the nearest 0.1 g.

Table 2

Student t Distribution Factors

| n | 8 | 10 | 12 | 15 |

| t10, n-1 | 1.42 | 1.38 | 1.36 | 1.34 |

1.9.2 Fresh Concrete

Three samples, each of known volume, shall be taken from fresh concrete. The samples shall weigh 8-10 lbs each. The fiber from each sample should be carefully washed out of the fresh concrete. Ensure that all the fiber is washed until clean then dried and then weighed (mf) to the nearest 0.1 g.

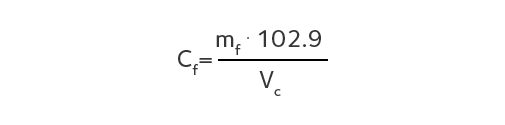

1.9.3 The fiber content of each sample shall be calculated from the determined fiber mass and sample volume, using the formula:

Where:

Cf = fiber content (lbs/yd3)

mf = mass of fiber extracted from the sample (g)

Vc = volume of the sample (inch3)

1.9.4 The report shall contain:

- Specimen identification

- Specimen type (hardened or fresh), sizes and volumes

- Date and time of testing

- Description of fiber type

- Calculated fiber content of each sample and the mean value of the three samples

References

ASTM Standards:

1. ASTM C1399-04, “Test Method for Obtaining Average Residual-Strength of Fiber Reinforced Concrete,” ASTM International.

2. ASTM C1116-03, “Standard Specification for Fiber Reinforced Concrete and Shotcrete,” ASTM International.

5. ASTM C42-04, “Standard Test Method for Obtaining and Testing Drilled Cores and Sawed Beams of Concrete,” ASTM International.

ACI Standards and Reports:

3. & 4. – Building Code Requirements for Structural Concrete (318-02) and Commentary (318R-02)

gcpat.com | North America Customer Service: +1 (877) 423 6491

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

© Copyright 2018 GCP Applied Technologies Inc. All rights reserved.

.

In Canada, 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 475, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2024-06-21

https://gcpat.com/en/solutions/products/strux-synthetic-macro-fibers/tb-1207-a-guide-specifying-use-synthetic-macro