/ concrete / mix design

ECLIPSE® shrinkage reducing admixture is a liquid concrete admixture which reduces material shrinkage due to drying. This technical bulletin outlines recommended shrinkage testing mix matrices, reviews pertinent sections of ASTM C157, “Standard Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete,” and details a suggested format for reporting laboratory shrinkage test results. The Technical Bulletin is relevant for ECLIPSE® 4500 and ECLIPSE® Floor 200.

Shrinkage Testing Mix Matrix

- Water content, mortar paste fraction, admixture selection, cementitious and pozzolan types and quantities, coupled with aggregate characteristics and mix design proportions most significantly impact concrete’s drying shrinkage characteristics. Careful selection of these variables are critical when designing and testing low shrinkage mixes.

- Drying shrinkage properties of ECLIPSE® admixed concrete is typically, but not always, linear from 1% to 2.5% by weight of cement ECLIPSE® dosage rates. Therefore, it is recommended concrete admixed with, at a minimum, low and high dosage rates of ECLIPSE® be included in the shrinkage test matrix.

- Reference concrete containing no ECLIPSE® must be included in the test matrix. This is essential because ECLIPSE® admixed concrete shrinkage performance is measured relative to reference concrete shrinkage performance.

- It is recommended both superplasticized and mid-range water reduced mixes be incorporated into the shrinkage test matrix, since these admixtures may optimize reductions in drying shrinkage.

ASTM C157 Shrinkage Test Procedure (including Recommended Modifications)

ASTM C157, “Standard Test Method for Length Change of Hardened Hydraulic-Cement Mortar and Concrete” is the most common and applicable procedure for determining length change of hardened hydraulic-cement concrete. This test procedure is rather detailed, therefore it is advisable that local laboratories clearly demonstrate shrinkage testing proficiency prior to the initiation of an ECLIPSE® shrinkage test program. Several specific ASTM C157 equipment requirements are depicted below (refer to applicable ASTM standard for further detail):

- 76 mm x 76 mm x 286 mm (3 in .x 3 in. x 11.25 in.) steel molds with 254 mm (10 in.) nominal gage lengths if all aggregate passes a 25 mm (1 in.) sieve. If the aggregate passes a 51 mm (2 in.) sieve, 102 mm x 102 mm x 286 mm (4 in. x 4 in. x 11.25 in.) steel molds are used (refer to ASTM C490 and ASTM C157)

- Length comparator and reference bar (refer to ASTM C490)

- Drying room with the capacity to maintain temperatures of 23.0 ± 1.7°C (73.4 ± 3°F) and relative humidity of 50 ± 4%. Horizontal drying room racks must allow for non restricted air circulation around shrinkage specimens (refer to ASTM C157)

- Storage tank for lime saturated water curing (refer to ASTM C511)

Concrete Sampling

Lab concrete shall be sampled in accordance with ASTM C192, while field concrete shall be sampled in accordance with ASTM C172. Plastic concrete tests including slump, air, unit weight and temperature shall be conducted and recorded for each concrete sample. Compressive strength testing shall be conducted at a minimum of 2 ages (including 28 days) and set time testing is also recommended.

Shrinkage Specimen Fabrication

Concrete shall be placed in shrinkage molds in two approximately equal layers and consolidated by rodding, unless the slump is less than 76 mm (3 in.), at which time vibration shall be used. The concrete shall be carefully hand worked around each gage stud, followed by striking off with a straight edge. The steel plates holding the gage studs at the end of each mold should be loosened after consolidation.

Curing from 0 Hours to 23 ± ½ Hours

ASTM C157 requires moist cabinet or moist room curing per ASTM C511 during the initial period. However, if the specimen top surfaces are covered with plastic or wet burlap, it should be acceptable to cure specimens in ambient conditions, since all of the specimen surface area will be covered, thereby not allowing moisture to migrate out. ASTM C157 test deviations should be noted in report.

Initial Shrinkage Reading

At time 23 ± ½ hour, specimens are carefully demolded and placed in lime saturated water maintained at 23.0 ± 1.7°C (73.4 ± 3°F) for minimum 30 minutes. At time 24 ± ½ hour, initial comparator readings (called 1 day reading) are taken on wiped down specimens, which are then placed back in the lime saturated water tank.

Lime Saturated Water Curing – 1 day up to maximum 28 days

ASTM C157 states “After the initial comparator reading, store the specimens in lime saturated water at 23.0 ± 1.7°C (73.4 ± 3°F) until they have reached an age of 28 days, including the period in the molds, unless another condition or duration of curing is specified”. THIS STATEMENT IMPLIES 28 DAY WET CURING IS NOT REQUIRED BY ASTM. GCP Applied Technologies recommends an additional 6 days of lime saturated water curing, which brings the specimen age to 7 days.

Note: ASTM C494, “Standard Specification for Chemical Admixtures for Concrete,” Section 17.1.4 Length Change states “Test specimens shall be tested in accordance with Test Method C157 except that the moist curing period, including the period in the molds, shall be 14 days”. This statement reaffirms that a 28 day moist cure is not absolutely required.

Air Curing/Shrinkage Readings

At 7 days, a second comparator reading is taken (called 7 day reading) and the specimens are placed on the drying room racks. This is the start of air curing, which should continue to minimum 56 days, but ideally to 365 days. Subsequent shrinkage readings are taken at an array of ages, often including, but not limited to 14, 21, 28, 35, 56, 90, 180 and 365 days.

Length Change Calculations

The pertinent value calculated from shrinkage test results is ΔL. ΔL is the length change in percent (%) of a specimen relative to the specimens initial (1 day) reading.

Length change (%) is calculated via

- ΔL = length change of specimen at a particular age, %

- CRD = difference between the comparator reading of the specimen and the reference bar at any age

- G = gage length, 254 mm (10 in.)

In this bulletin, negative ΔL values represent beam expansion, which is likely to occur during wet curing, with positive ΔL values representing beam shrinkage occurring during air curing.

ASTM C157 Data – Difference in Specimen Length versus Reference Bar (CRD) and Total Length Change versus 1 Day (ΔL-measured in %)

| Reference | Low ECLIPSE® | High ECLIPSE® | ||||

|---|---|---|---|---|---|---|

| CRD (avg. 3 bars) | ΔL (%) | CRD (avg. 3 bars) | ΔL (%) | CRD (avg. 3 bars) | ΔL (%) | |

| 1 day | 0.1735 | -- | 0.1808 | -- | 0.1843 | -- |

| 7 day | 0.1741 | -0.006 | 0.1813 | -0.005 | 0.1850 | -0.007 |

| 14 day | 0.1723 | 0.012 | 0.1801 | 0.007 | 0.1845 | -0.002 |

| 21 day | 0.1710 | 0.025 | 0.1792 | 0.016 | 0.1834 | 0.009 |

| 28 day | 0.1701 | 0.034 | 0.1788 | 0.020 | 0.1830 | 0.013 |

| 35 day | 0.1696 | 0.039 | 0.1784 | 0.024 | 0.1827 | 0.016 |

| 56 day | 0.1691 | 0.044 | 0.1778 | 0.030 | 0.1823 | 0.020 |

| 90 day | 0.1688 | 0.047 | 0.1777 | 0.031 | 0.1822 | 0.021 |

| 365 day | 0.1685 | 0.050 | 0.1776 | 0.032 | 0.1821 | 0.022 |

Suggested Format for Reporting ASTM C157 Test Results

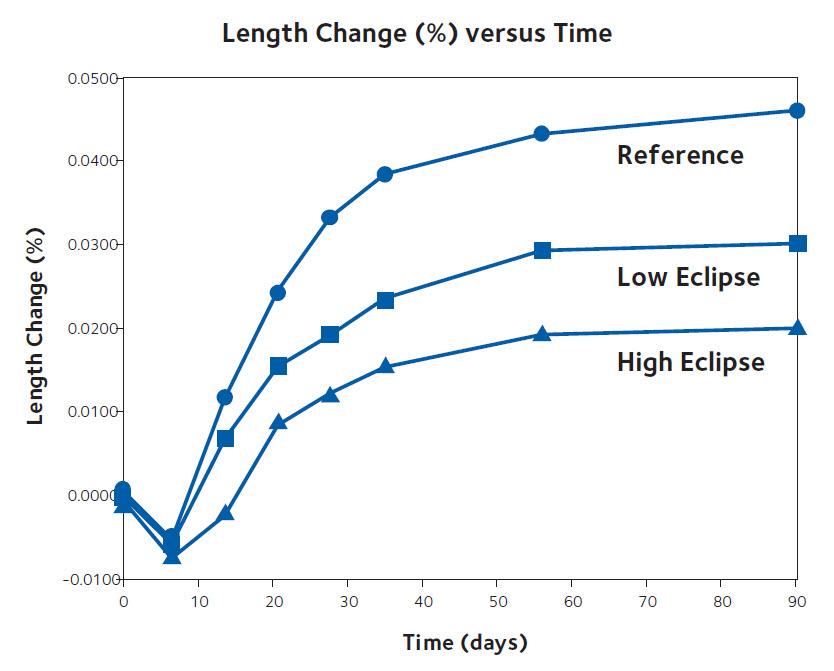

Average CRD and ΔL values for 3 shrinkage specimens is depicted in the table below. ΔL is easily calculated using the length change equation shown above and CRD data. The next step is to graphically plot ΔL or Length Change (%) on the Y axis versus Time (days) on the X axis. 365 day data is not depicted because it unnecessarily extends the length of the X axis, thereby compressing critical 0-90 day shrinkage data. Finally, ECLIPSE® concrete shrinkage data expressed as percent reduction compared to reference concrete is shown at right at 28, 90 and 365 days. This is the pertinent information engineers and specifiers will be requiring for confirmation of ECLIPSE® shrinkage performance.

ECLIPSE® Concrete versus Reference Concrete Shrinkage Performance (expressed as % Shrinkage Reduction of Reference)

| 28 day | 90 day | 365 day | |

|---|---|---|---|

| Low dosage ECLIPSE® | 41 | 34 | 36 |

| High dosage ECLIPSE® | 62 | 55 | 56 |

gcpat.com | North America Customer Service: +1 (877) 423 6491

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

ECLIPSE is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies Inc. All rights reserved.

.

In Canada, 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 475, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2024-06-21

https://gcpat.com/en/solutions/products/eclipse-concrete-shrinkage-reducing-admixtures/tb-1000-eclipse-shrinkage