POSTRITE® Preventive Maintenance System

POSTRITE® is an innovative spray applied liquid corrosion inhibitor used for the repair of reinforced concrete which has been damaged by chloride-ion induced corrosion. POSTRITE® is a unique and patented combination of corrosion fighting components designed specifically to meet the special requirements and needs of concrete repair professionals. When applied, POSTRITE® permeates into the concrete and protects the reinforcing steel by surrounding it with a proven corrosion inhibitor.

When to Use POSTRITE®

POSTRITE® is intended for the repair of concrete that has experienced damage due to chloride induced corrosion of embedded steel reinforcement. POSTRITE® will be beneficial in repair situations

where unsound/damaged concrete will be removed and a concrete overlay or patch applied to the repair area.

It is commonly accepted that when one portion of a corrosion damaged area requires patching, adjoining areas susceptible to the same levels of chloride will need similar attention. These conventional repairs are repetitive, expensive, disruptive and in the long run, ineffective. The POSTRITE® Preventive Maintenance System is a new technology that makes such procedures obsolete.

Concrete Removal

The extent of repair will, to some extent, dictate how the concrete will be removed. In all cases, concrete in the repair area(s) must be removed to produce no more than 12 mm (1⁄2 in.) of concrete cover over the reinforcing steel. In some cases, additional benefits may be provided by removal of more or all of the concrete cover (hence, exposure of the reinforcing steel is acceptable). The actual depth of cover should be confirmed and documented with random measurements [one measurement per every 18.6 m2 (200 ft2) or 15 total measurements, whichever is greater] by a commercially available pachometer. Uniform removal of the concrete cover can be accomplished by a variety of methods including milling, scarification, or shot-blasting. If hydrodemolition or any other method is used, the concrete surface must be completely dry before POSTRITE® is applied.

After removing unsound concrete, the repair area(s) should be inspected for any previously undetected delaminated or unsound areas. Any additional unsound areas should be removed. Deep sections — areas with localized concrete removal well below the level of the reinforcing steel — should be filled with a cementitious-based patch mix containing 20 L/m3 (4 gal/yd3) of DCI® Corrosion Inhibitor. The patch should be cured in accordance with ACI or the patch mix manufacturer recommendations.

Surface Preparation

The repair surface should be dry, clean, and free from loose debris. Residual material from the concrete removal process such as dust, grit, or rubble must be removed from the area prior to the POSTRITE® treatment. Blowing with compressed air, vacuuming, and thorough dry sweeping of the area are examples of acceptable techniques. The concrete should also be free from any substances which could interfere with the penetration of the POSTRITE® into the concrete, e.g. oils, sealers, resins, etc. The concrete must be dry prior to application of the POSTRITE®. This will speed the rate at which the POSTRITE® penetrates into the concrete. Care should be taken to prevent moisture — including rain, heavy dew, or water draining from other surfaces — from contacting the concrete surface.

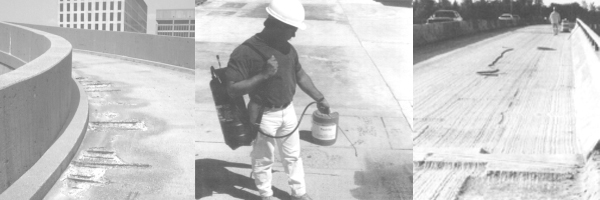

POSTRITE® Application

POSTRITE® is a water-based solution which is spray-applied, using a conventional back-pressure liquid applicator, onto the concrete. The treatment process consists of three applications, each at a rate of 0.33 L/m2 (1 gal/125 ft2). POSTRITE® should be applied evenly across the entire repair surface.

Additional levels of protection can be achieved by applying additional coatings of POSTRITE® prior to installation of the concrete overlay. POSTRITE® contains a water-soluble green dye to provide the applicator a visual indication of where the product has been applied. The green color will not permanently stain existing concrete surfaces that come in contact with any overspray.

Each of the three, or more, applications should be allowed to permeate into the concrete before the next treatment is applied. The concrete is ready for the next application when the surface loses its sheen (the surface will still have a green tint) and has no liquid POSTRITE® solution on the surface. The actual moisture conditions of the concrete will influence the rate at which POSTRITE® permeates into the surface. In general, waiting one to two hours after the first application is recommended, up to four to six hours following the second application, and six to twelve hours after the third application.

At no time should POSTRITE® be allowed to puddle or accumulate on the concrete surface. Any puddles should be brushed or broomed to more evenly distribute POSTRITE®. If the recommended application sequence results in puddling, a lesser amount of POSTRITE® with additional applications should be used. However, for the application process to be complete, the concrete must have had a treatment of at least 1 L/m2 (3 gal/125 ft2) of POSTRITE®. If the surface being treated is sloped, the rate of application may have to be modified to prevent POSTRITE® from flowing down the slope.

During and between the application periods, while POSTRITE® is permeating into the concrete, the surface should be protected from moisture such as rain, heavy dew, or water draining from the other surfaces. It is safe to walk on the treated surfaces.

Preparation for Overlay

POSTRITE® remaining on the surface from the final application should be allowed to permeate into the concrete prior to overlay placement. POSTRITE® improves the bond strength between the overlay and the underlying concrete; however, a bonding grout can be used if specified by the engineer of record. All bonding grouts must be cementitious based, containing no polymers or latex. The neat cement paste bonding grout should be applied to the surface immediately prior to overlay placement, and should not be allowed to dry out prior to overlay placement.

Overlay Concrete

The concrete overlay shall contain DCI Corrosion Inhibitor at a dosage rate of 20 L/m3 (4 gal/yd3) of concrete. The overlay shall provide at least 37 mm (11⁄2 in.) of cover. The engineer of record shall approve the mix design for overlay use. Low water-to-cement ratio, highly durable, lowpermeability concretes are desired. Generally, these highperformance concretes will produce less bleed water than “normal” concrete. Therefore, ACI 302 “Guide for Concrete Floor and Slab Construction” and ACI 308 “Standard Practice for Curing Concrete” should be followed during placement, finishing and curing of the concrete overlay.

Wet curing is the preferred method for curing high performance concretes. The burlap should cover all flatwork and be kept wet for a minimum of seven days or until the time necessary to attain 70% of the specified compressive strength.

Packaging/Handling

POSTRITE® is available in 210 L (55 gal) drums and 19 L (5 gal) pails. POSTRITE® should be protected from freezing. However, if the product should freeze, the corrosion inhibiting properties

can be restored by thawing and thorough mechanical agitation.

Safety/First Aid

POSTRITE® complies with environmental VOC regulations and is non-flammable. As with most chemical substances, care should be taken to avoid contact with skin and eyes. Safety goggles and rubber gloves are recommended. Approved respiratory protection should be worn during the spray application and good personal hygiene should be used to avoid ingestion. Please read the Material Safety Data Sheet for more complete information.

gcpat.com | North America Customer Service: +1 (877) 423 6491

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation or suggestion is intended for any use that would infringe any patent, copyright or other third-party right.

POSTRITE is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies, Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2020 GCP Applied Technologies, Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 475, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2024-06-21

https://gcpat.com/en/solutions/products/postrite-spray-applied-corrosion-inhibitor/postrite-data-sheet