DUCTILCRETE

TOOLS1. 4" & 6” Right Angled Grinders. |

|

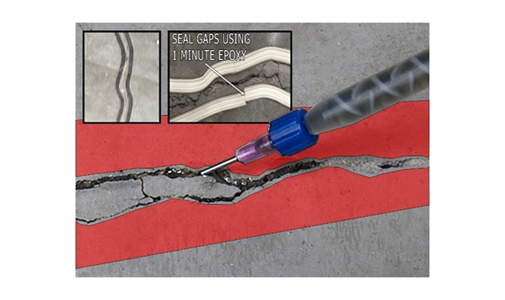

MATERIALS1. 10-Minute Gray Concrete Mender

|

4. Silica Sand |

FINISH OPTIONSNOTE: For best results prepare color samples to ensure the best color match is being used when repairing cracks. 1. Finish Option 1 – Gray Concrete Mender • Install 10 Minute Mender. |

|

2. Finish Option 2 – Silica Sand/color sanded grout • Cap off the top ¼” of the repair using a sand mixture comprised of Charcoal Gray Sanded Grout for tile mixed with Silica Sand. |

|

3. Finish Option 3 – Rapid Refloor or other epoxy installed in the top layer • Cap off the top ¼” of the repair with Rapid Refloor or other epoxy in a color that best matches the floor. |

REPAIR PROCEDURES1. FILL THE BOTTLES WITH SAND • Use as a binder when repairing wider cracks. |

|

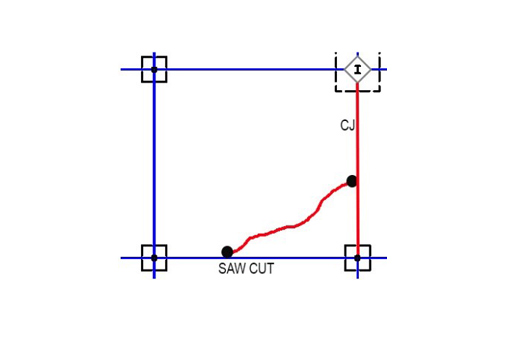

2. DRILL HOLES IF REQUIRED • Prevents run-off into adjacent joints. |

|

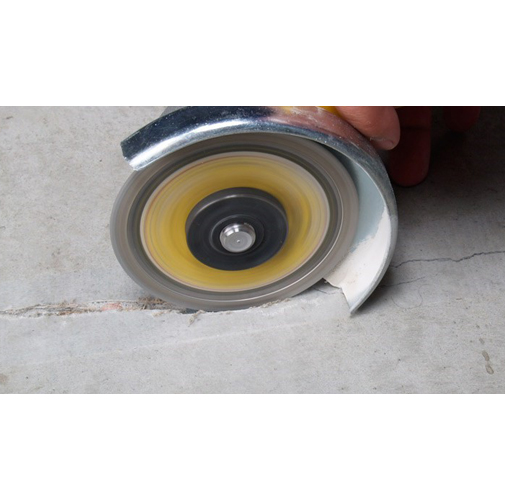

3. SELECT NEEDLE SIZE • There are 2 static mixing needle tips available for use with the 10 Minute Mender cartridges. Listed below are their outside diameters. |

|

4. PREPERATION • If the crack is tighter than 1.25mm it is recommended to wait until the crack widens to a width that the 18 gauge / 1.25 mm tip can be inserted into the crack. 10 Minute Mender Crack Injection Video

|

|

5. PROTECT, VACUUM, INSTALL MATERIAL • Install tape, weather stripping or other along the crack. |

FINISH OPTIONSFinish Option 1 – Gray Concrete Mender 1. Fill the crack to refusal leaving the Mender slightly high. |

|

Finish Option 2 – Silica Sand / Sanded Grout 1. Fill the crack to refusal leaving the Mender slightly low. |

|

Finish Option 3 - Cap-off the repair using a tinted repair product. 1. Fill the crack to refusal but leaving the 10 Minute Mender 1/8” – 1/4” below the top of the existing floor. |

gcpat.com | North America Customer Service: +1 (877) 423 6491

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

DUCTILCRETE is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2020 GCP Applied Technologies Inc. All rights reserved.

.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 475, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2024-06-21

https://gcpat.com/en/solutions/products/ductilcrete-engineered-slab-systems/crack-repair-procedure-narrower-0016in