There are myriad options when it comes to fiber reinforced concrete, and it can be confusing to determine the right type of reinforcement for each application.

In engineering design, there are two types of reinforcement and they are distinctly different from each other: Primary reinforcement, also known as structural steel, is designed to carry loads. Secondary reinforcement, commonly referred to as “temperature and shrinkage steel,” is used to minimize the effects of drying shrinkage and thermal expansion and contraction.

It’s important to note that neither welded wire reinforcement nor synthetic fibers can be used to replace primary reinforcement. However, they both can be used for secondary reinforcement. Also, secondary reinforcement does not stop cracks from forming, but serves to limit the propagation and opening width once they do form.

Properly designed, constructed, and jointed un-reinforced concrete slabs often do not require temperature and shrinkage reinforcement. However, these conditions rarely exist in the real world. Therefore, mitigation of cracking induced by conditions such as subgrade restraint, subgrade settlement, drying shrinkage, and thermal expansion and contraction should be considered in virtually all cases. This secondary reinforcement is needed for minimizing crack propagation and crack width openings for applications such as slabs-on-ground, composite steel floor deck assemblies, topping slabs, and thin-walled precast overlays.

Advantages of synthetic fibers

Synthetic fibers offer many advantages over welded wire reinforcement. Welded wire reinforcement takes time to transport, install, and place at the appropriate depth in the slab. It must be placed between the middle and upper third of the slab, which is cumbersome work, often improperly done, and is a serious trip hazard.

A faster, less labor-intensive, and safer alternative is to use lightweight synthetic fibers, which are dispersed into the concrete mix itself. Typically made of polypropylene or polyethylene, these fibers mitigate many forms of cracking, minimizing the length and width of any cracks that occur.

Choosing between macrofibers and microfibers

Microfibers are used in concrete to reduce plastic shrinkage cracks. Plastic shrinkage cracks are those that form while the concrete is still plastic, or able to be moved. These cracks are typically caused by loss of moisture at the surface of the concrete. Microfibers also help to increase bleed water uniformity, which helps with finishing.

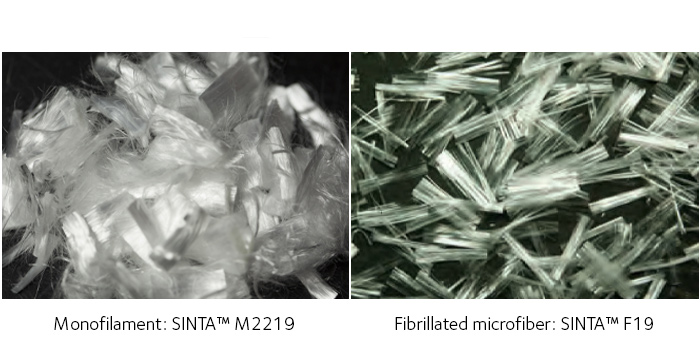

Microfibers come in two varieties:

- Monofilament, which are akin to individual strands of silk

- Fibrillated microfibers, which are more like nets cast into the concrete

Microfibers can be used to augment welded wire reinforcement. However, they cannot be used to replace welded wire reinforcement when needing equal flexural performance.

Macrofibers are generally used to minimize and/or eliminate both plastic and drying shrinkage cracking. They can be used to replace welded wire reinforcement and provide equal or better performance when the proper dosage is used. Macrofibers provide all the benefits of microfibers, in addition to increased durability, flexural toughness, and resistance to impact and abrasion.

| Type of synthetic fiber | Diameter | Dosage |

| Macrofibers | Equal to or greater than 0.12 inches (0.3mm) | Typically 0.2-1% by volume or higher |

| Microfibers | Less than 0.12 inches (0.3mm) | Typically 0.05-0.2% by volume |

Determining the right amount of reinforcement

Once the appropriate fiber type has been selected, the proper dose must be determined. For microfibers, determining the correct dosage is relatively easy. For most applications, a monofilament fiber such as SINTA™ M2219 or SINTA™ M3019 at a dosage rate of 0.5 to 0.75 pounds per cubic yard of concrete will perform adequately. For fibrillated microfibers such as SINTA™ F19 or SINTA™ F38, the typical dose is between 0.75 and 1.5 pounds per cubic yard.

Determining the proper dosage rate of macrofibers can be a bit more complicated. This starts with determining the purpose of the macrofibers for the chosen application. For the majority of residential and commercial slabs on ground, a dosage rate of 3.0 pounds per cubic yard of STRUX® 90/40 or 75/32 will perform adequately to provide temperature and shrinkage protection. However, if looking to do more, consult an engineer who is well versed in fiber reinforced concrete design.

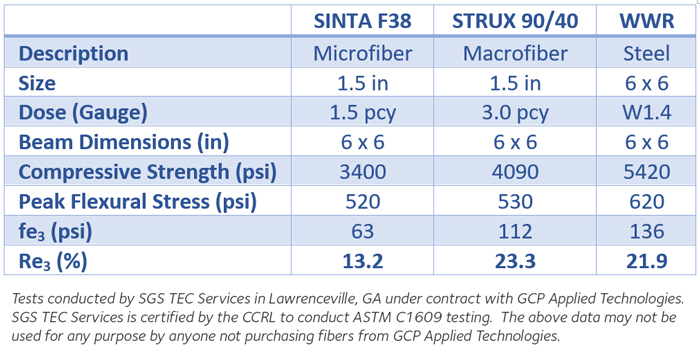

Understanding ACI 544.4 R-18 Guide to Design with Fiber Reinforcing Concrete provides easy-to-follow design guidelines for fiber-reinforcing concrete in structural and nonstructural applications. In addition, ASTM C1609/C1609M can be used to compare synthetic fibers and welded wire reinforcement. Using these tests, STRUX® 90/40, a synthetic macrofiber, added to concrete at a rate of 3.0 pounds per cubic yard exceeds the performance of welded wire reinforcement as shown in the table below comparing Re,3 performance. STRUX® 75/32 provides similar performance.

Specialty Flooring

Some fiber companies try to claim that fibrillated microfibers are an equivalent replacement to welded wire reinforcement. The data above shows that the fibrillated fiber type commonly offered as an equivalent replacement to welded wire reinforcement does not provide equivalent performance. While they do offer many benefits, some of which welded wire reinforcement cannot; they are not an “equal” replacement.

Dosage rates made easy

The free STRUX® macro synthetic fiber calculator is a next-generation tool that gives you the ability to choose the level of performance you need in the slab, and recommends the correct dosage rates for STRUX® 90/40 fibers as a replacement for welded wire reinforcement for your specific application. Simply input the specified welded wire reinforcement as well as the compressive strength and thickness of the slab. The calculator then generates a report identifying the dosage rate needed to achieve the desired performance. The app also generates a submittal package for a design professional or code official, showing the calculations used to determine the dosage rates recommended. The app then generates a cost analysis between STRUX® synthetic macro fibers and welded wire reinforcement.

Learn more about fiber-reinforced concrete.

Tags

- Building Envelope Solutions

- Concrete

- Contractor

- SINTA

- STRUX

- Structural Solutions

- Subcontractor