Contact an Air Barrier Specialist today

Product Description

PERM-A-BARRIER® NPS (Non Permeable Sheet) Wall Membranes are ideal for protecting the building superstructure from the damaging effects of the elements. By minimizing air and water vapor flow through the building exterior, PERM-A-BARRIER® NPS Wall Membranes:

- Prevent premature deterioration of the building envelope

- Enhance thermal performance of the structure and save energy costs

- Improve comfort for the building occupants

Product Advantages

- Primer-less self-adhered sheet—reduces installation time

- Fire Resistant—meets NFPA 285 as part of various wall assemblies with foam plastic insulation

- Fully bonded—transmits wind loads directly to the substrate

- Waterproof and virtually impermeable to moisture—virtually impermeable to the passage of liquid water and vapor

- Air tight— Protects against air passage and associated energy losses. Meets ASTM E2357 standard as required by IECC 2012

- Flexible—accommodates minor settlement and shrinkage movement

- Controlled thickness—factory made sheet ensures constant, non-variable site application

- Aggressive, conformable adhesive—allows selfsealing around mechanical fasteners

- Wide application window— primerless application at surface and ambient temperatures of 25°F (-4°C) and above.

System Components

- PERM-A-BARRIER® NPS Wall Membrane— for use at installation temperatures above 25°F (-4°C)

- PERM-A-BARRIER® Adhesive - Adhesive for difficult to bond areas

- PERM-A-BARRIER® Universal Flashing & Sealant- one part moisture curing, STPE sealant for sealing penetrations, terminations, brick ties, final terminations & flashing application. PERM-A-BARRIER® Universal Flashing & Sealant can be applied under all GCP air and weather barrier, and over most of them (limitation: PERM-A-BARRIER® VPS 30).

- BITUTHENE® Mastic—rubberized asphalt mastic for sealing penetrations, terminations, brick ties, etc.

- BITUTHENE® Liquid Membrane—two component, trowel grade, asphalt modified urethane for sealing patches, terminations, brick ties, etc.

- PERM-A-BARRIER® Wall Flashing—fully adhered through wall flashing system

- PERM-A-BARRIER® NPS Flashing—fully adhered flashing for protecting and sealing critical detail areas

Installation

Safety

PERM-A-BARRIER® products must be handled properly. Vapors from the mastic and solvent-based primer are harmful and flammable. For these products, the best available information on safe handling, storage, personal protection, health and environmental considerations has been gathered. Refer to product label and Safety Data Sheet before use. All users should acquaint themselves with this information prior to working with the material. Carefully read detailed precaution statements on the product labels and SDS before use. SDSs can be obtained from our web site or by contacting us toll free at 866-333-3SBM (3726).

Surface Preparation

Surface must be smooth, clean, dry and free of voids, spalled areas, loose aggregate, loose nails, sharp protrusions or other matter that will hinder the adhesion or regularity of the wall membrane installation. Clean loose dust or dirt from the surface to which the wall membrane is to be applied by wiping with a clean, dry cloth or brush. In cold temperature installations do not apply over ice or frost. It is best practice to spray primer or adhesive onto gypsum cut edge to reduce dust. Ensure solvent flashes off completely before applying Perm-A-Barrier NPS

.

GCP Applied Technologies Perm-A-Barrier products are ideal for a wide variety of substrates, including, but not limited to, block, poured concrete, gypsum, plywood and OSB. Please contact your local GCP Applied Technologies Representative for any questions regarding other substrates.

Certain substrate conditions may require the use of a GCP primer. Contact your local GCP Applied Technologies Representative for information.

Temperature

PERM-A-BARRIER® NPS Wall Membrane may be applied without primer to dry substrate when air and surface temperatures are above 25°F (-4°C).

Membrane Application

Cut membrane into easily handled lengths. Apply membrane horizontally or vertically to substrates receiving post-applied masonry anchors (ties), such as gypsum sheathing.

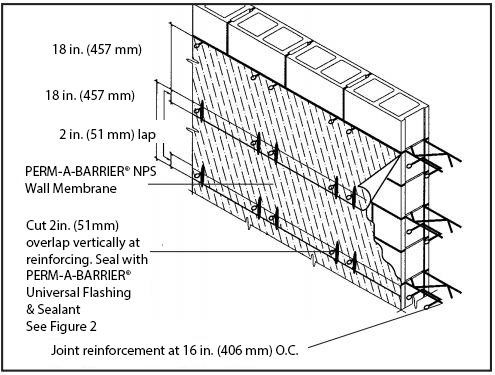

Apply PERM-A-BARRIER® NPS Wall Membranes horizontally to blockwork with projecting masonry anchors (ties), beginning at the base of the wall. Each length of the membrane must be installed so that the upper edge runs continuously along the underside of the line of masonry anchors (ties). Subsequent sheets applied above must overlap the sheet below by 2 in. (51 mm) immediately below the line of anchors (ties). Since the membrane width appropriate for this application of 18 in. (457 mm) is wider than the typical spacing between the lines of anchors (ties) 16 in. (406 mm), it will be necessary to cut the membrane at the location of the tie wires projecting from the wall to enable the sheet to be laid in place. End laps that occur in subsequent lengths that follow should maintain a minimum overlap of 2 in. (51 mm). See Figures 1 and 2.

The membrane must be pressed firmly into place with a hand roller or the back of a utility knife as soon as possible, ensuring continuous and intimate contact with the substrate to prevent water from migrating under the membrane.

In certain applications such as on soffits, ceilings or substrates such as oriented strand board (OSB), backnail the membrane along the side lap prior to installing the next sheet of membrane to ensure positive contact to the substrate.

Additional fastening may be required through the field of the membrane in these applications and must be sealed with PERM-A-BARRIER® Universal Flashing & Sealant, BITUTHENE® Liquid Membrane or BITUTHENE® Mastic.

Apply PERM-A-BARRIER® Universal Flashing & Sealant, BITUTHENE® Mastic or BITUTHENE® Liquid Membrane to seal around the tie wire projections. Fit the PERM-A-BARRIER® NPS Wall Membrane tightly around all penetrations through the membrane and seal using PERM-A-BARRIER® Universal Flashing & Sealant or BITUTHENE® Liquid Membrane.

Continue the membrane into all openings in the wall area, such as windows, doors, etc., and terminate at points that will prevent interior visibility. The installation must be made continuous at all framed openings.

Coordinate installation of the PERM-A-BARRIER® NPS Wall Membrane with the roofing trade to ensure continuity with the roofing system at this critical transition area.

At the end of each working day, if the wall has been only partially covered, apply a bead of BITUTHENE® Mastic or BITUTHENE® Liquid Membrane along the top edge of the membrane at its termination to prevent vertical drainage of precipitation from penetrating the end and undermining the membrane adhesion. Tool the BITUTHENE® Mastic or BITUTHENE® Liquid Membrane to ensure it is worked into the surface. For final terminations that will not be covered with membrane, PERM-A-BARRIER® Universal Flashing & Sealant can be used in lieu of BITUTHENE® Mastic or BITUTHENE® Liquid Membrane. Inspect the membrane before covering and repair any punctures, damaged areas or inadequately lapped seams.

All non water shedding edges must be sealed with PERM-A-BARRIER® Universal Flashing & Sealant, BITUTHENE® Liquid Membrane or BITUTHENE® Mastic.

Membrane Repairs

Repairs must be made using PERM-A-BARRIER® NPS Wall Membrane sized to extend 3 in. (75mm) in all directions from the perimeter of the affected area. The repair piece must be pressed into place with a hand roller as soon as possible to ensure continuous and intimate contact with the substrate. When sealing the patch if placed in a diamond pattern both water sheading edges will need sealant. If the patches are placed straight, then the top edge and minimum of 3” down each side will need sealant termination. If the sealing patch is horizontal, then all edges will need sealant termination. To repair gaps which are less than 1/8 inch in diameter (fish mouth gaps) cover with ‘Perm-A-Barrier Universal Flashing & Sealant’ extending 2 inches in diameter from the gap.

Membrane Protection

PERM-A-BARRIER® NPS Wall Membranes must be protected from damage by other trades or construction materials.

Figure 1: Membrane System Detail

Figure 2: Horizontal Reinforcing

Storage and Handling Information

All materials must be protected from rain and physical damage. Pallets of PERM-A-BARRIER® NPS Wall Membrane must not be double stacked on the job site. Provide cover on top and all sides, allowing for adequate ventilation. Store membrane where temperatures will not exceed 90°F (32°C) for extended periods. All products must be stored in a dry area away from high heat, flames or sparks. Store only as much material at point of use as is required for each day’s work.

Limitations

PERM-A-BARRIER® NPS Wall Membranes must not be applied in areas where it will be exposed to direct sunlight permanently, and must be covered within 1 year. Refer to Technical Letter 19, Exposure Guidelines for PERM-A-BARRIER® Self-Adhered Membranes.

Maximum In Service Temperature (as installed) is 160°F (71°C)

Warranty

PERM-A-BARRIER® products are warranted to be free of defects in manufacture for a period of 5 years. Material will be provided at no charge to replace any defective product.

Technical Service

Support is provided by full-time technically trained GCP Applied Technologies field sales representatives and technical service personnel, backed by a central research and development technical services staff.

Supply

| Product | Unit of Sale | Approximate Coverage | Weight | Palletization |

|---|---|---|---|---|

| PERM-A-BARRIER® NPS Membrane | 1 roll | 418 ft2 (38.8 m2) per roll 46 in. X 109 ft (1.17 x 33.22m) roll | 59 lbs/roll | 25 cartons (25 rolls) per pallet |

| PERM-A-BARRIER® Wall Flashing | ||||

| 12 in. (305 mm) 18 in. (457 mm) 24 in. (610 mm) 36 in. (914 mm) | 3 rolls 2 rolls 1 roll 1 roll | 75 linear ft per roll 75 linear ft per roll 75 linear ft per roll 75 linear ft per roll | 25 lbs/roll 37.5 lbs/roll 55 lbs/roll 75 lbs/roll | 25 cartons (75 rolls) per pallet 25 cartons (50 rolls) per pallet 25 cartons (35 rolls) per pallet 25 cartons (25 rolls) per pallet |

| PERM-A-BARRIER® Aluminum Flashing | ||||

| 6 in. (152 mm) 9 in. (225 mm) 12 in. (305 mm) | 12 rolls 6 rolls 6 rolls | 50 linear ft per roll 50 linear ft per roll 50 linear ft per roll | 6 lbs/roll 9 lbs/roll 12 lbs/roll | 30 cartons (360 rolls) per pallet 30 cartons (180 rolls) per pallet 30 cartons (180 rolls) per pallet |

| BITUTHENE® Mastic - 5 gal pail | 1 pail | approx. 120 ft2 at 60 mils | 54 lbs/pail | 36 pails per pallet |

| BITUTHENE® Mastic - 30 oz tube | 12 tubes | approx. 30 linear ft x 1/4 in. bead | 32 lbs/carton | 72 cartons (864 tubes) per pallet |

| PERM-A-BARRIER® Universal Flashing & Sealant Sealant- 29 oz. Cartridge | 1 cartridge | approx. 30 linear ft x 1/4 in. bead | 29 oz. cartridge | 10 cartridges/ carton 42 cartons/ pallet |

| BITUTHENE® Liquid Membrane - 1.5 gal pail | 1 pail | approx. 200 Linear ft/gal @ 1” wide x 90 mils. | 16 lbs/pail | 100 pails per pallet |

| BITUTHENE® Liquid Membrane - 4 gal pail | 1 pail | approx. 200 Linear ft/gal @ 1” wide x 90 mils. | 44 lbs/pail | 24 pails per pallet |

| PERM-A-BARRIER® Adhesive - 5 gal pail | 1 pail | 250-300 ft2/gal (7-7m2/L) | 43 lbs/pail | 36 pails / pallet |

Physical Properties

| Property | Perm-A-Barrier NPS Wall Membrane | Test Method |

|---|---|---|

| Thickness includes HDPE Film | 0.018 in. (0.46 mm) | ASTM D3767 method A |

| Minimum tensile strength, membrane | 400 psi (2.8 MPa) | ASTM D412 |

| Minimum tensile strength, film | 5000 psi (34.5 MPa) | ASTM D412 |

| Minimum elongation, to failure | 200% | ASTM D412 |

| Pliability, at 180° bend over 1 in. (25 mm) mandrel | Pass at -20°F (-29°C) | ASTM D1970 |

| Crack cycling, 1/8 in. (3.2 mm) at -25°F (-32°C) | Pass | ASTM C1305 |

| Nail Sealability | Pass | ASTM D1970 |

| Minimum puncture resistance, membrane | 40 lbs (178 N) | ASTM E154 |

| Lap peel adhesion at minimum application temperature | 3.5 lbs/in. | ASTM D1876 |

| Maximum permeance to water vapor transmission | <0.01 perms / 0.02 perms | ASTM E96 Method A/ Method B |

| Water resistance of in-place membrane | Pass at >15 psf | ASTM E331 |

| Air permeance of in-place membrane1 | < 0.02 L/s/m2 (0.004cfm/ft2) | ASTM E2178 |

| Assembly air permeance at 1.57 psf (75 Pa) pressure difference1 | < 0.02 L/s/m2 (0.004cfm/ft2) | ASTM E2357 |

| Water absorption (weight gain at 48 hours) | 0.1% | ASTM D570 |

| Wall assembly fire test | Pass as part of various wall assemblies with foam plastic insulation2 | NFPA 285 |

| Peel Adhesion to Gypsum board | >5 pli | ASTM D903 |

| Peel adhesion to concrete | >5 pli | ASTM D903 |

Footnote:

1. Air permeance measured at a pressure differential of 1.57 psf (75 Pa).

2. Specific wall assemblies are available at gcpat.com.

gcpat.com | North America Customer Service: +1 (877) 423 6491

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

BITUTHENE and PERM-A-BARRIER are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 400, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-13

https://gcpat.com/en/solutions/products/perm-a-barrier-nps-air-barrier/perm-a-barrier-nps-wall-membrane