Product Description

SILCOR® PMMA HG is a two-component, high performance, fast-curing, cold hand-applied liquid waterproofing membrane. SILCOR PMMA HG can be applied to variety of substrate including concrete, masonry, and steel that provides a continuous, tough, and flexible seamless coating for podium decks, terraces, and balconies. The product is specially formulated using advanced Polymethylmethacrylate (PMMA) resin technology.

Product Advantages

- High Performance Waterproofing Membrane

- Seamless & fully bonded to substrate

- Strong inter-coat adhesion

- Unlimited overcoating window

- Fast cure and Easy Application

- Unaffected by high humidity

- Can be applied in one or two coats

- Simplifies application to irregular profiles & complex details

- Provides quick access to hard to reach areas

- Superior Durability & Weather Resistance

- Tough & flexible, able to accommodate differential movement

- Excellent crack bridging capability

- Chemical & UV resistance

Installation Data

SILCOR® PMMA HG can be applied at temperatures between 32°F - 86°F (0˚C - 30˚C)

SILCOR® PMMA HG Winter Grade 32°F – 59°F (0˚C - ˚15C)

SILCOR® PMMA HG Summer Grade 50°F – 86°F (10˚C - ˚30C)

System Components

GCP has a range of products to complement the SILCOR® PMMA HG System. These include:

- SILCOR® PMMA Concrete Sealer – Fast-curing, high-strength reactive resin used with SILCOR® PMMA Powder Cat to form a strong cohesive bond to substrates and seal surfaces.

- SILCOR® PMMA Metal Primer – Fast-curing, high-strength reactive resin used with SILCOR® PMMA Powder Cat to form a strong cohesive bond to metal substrates.

- SILCOR® PMMA Powder Cat – BPO Initiator to be used with SILCOR® PMMA HG, Concrete Sealer and Metal Primer

- SILCOR® PMMA Fabric - Polyester threads woven into a mesh pattern used as reinforcement specially designed for compatibility with SILCOR® PMMA HG

Packaging & Storage;

Product Kit Size

SILCOR® PMMA HG (Winter/Summer) 20 kg (4.6 gal)

SILCOR® PMMA Concrete Sealer 5 kg (1.2 gal)

SILCOR® PMMA Powder Cat 100g pouch 10 pouch/box

SILCOR® PMMA Metal Primer 5 kg (1.2 gal)

SILCOR® PMMA Fabric 12" x 328' per roll (4 rolls/box)

Storage & Handling

Safety regulations. Storage temperature must not exceed 77°F (25°C). Store cool and dry, out of direct sunlight. Do not store near open flame or food. the components a shelf life of one year at a minimum in the original unopened container. If your product is more than twelve months old, you must contact the Technical Service Department before use. Please refer to SILCOR® PMMA HG technical data sheet and details for application instructions.

Health & Safety

Refer to and read individual component safety data sheets and information sheets for further information. Immediately install entire contents of the pail after mixing, do not exceed recommended pot life of the material.

Coverage

- SILCOR® PMMA Concrete Sealer - apply at a rate of 80 – 175 sf/gal (0.25 – 0.50kg/m2), Excessively porous substrates may require a second application.

- SILCOR® PMMA Metal Primer: apply at a rate of 100 – 175 sf/gal (0.33 – 0.53kg/m2), depending on the texture of the substrate.

- SILCOR® PMMA HG liquid membrane:

- Horizontal Application – apply single coat at 33.2 sf/gal at 80mil (2.8kg/m2 at 2mm) dry thickness or as a two-coat system of 16.6 sf/gal/40mil (1.4kg/m²/coat)

- Vertical Application - applied in two even coats of 16.6 sf/gal/40mil (1.4kg/m²/coat/1mm) to achieve a minimum dry film thickness of 80mil (2mm).

Surface Preparation

Liquid Applied waterproofing systems are dependent on the quality of surface preparation.

Concrete: The substrate must be dry and free from oil, grease, dirt, bituminous and other contaminants. Unsound concrete and laitance shall be removed by appropriate mechanical means. All the cement dust should then be removed from the substrate. All bug holes, cracks and voids must be cleaned of debris and moisture by vacuum or compressed air and be filled. For suitable materials please contact our Technical Services Department.

Metal: The substrate must be dry and free from oil, grease, dirt and other contaminants. All loose rust and scale must be removed with appropriate mechanical means. For outside applications, PRIMER MR6 should be applied as soon as possible (4 hours) to newly prepared surfaces

For other substrate preparation and application-related question contact GCP Technical Services.

For compatibility with other construction materials or where additives, cement replacement or curing compounds have been used please consult the Technical Services Department.

Substrate Bond/Adhesion Test

Prior to full application of the Concrete Sealer or MR6 primer, it is recommended that a bond/adhesion test should be conducted to determine adequacy of substrate preparation and adhesion. The bond/adhesion of the primer to the substrate should be greater than or equal to 290 PSI (2MPa). Some applications may require higher values. If low values are obtained, this would indicate that further preparation is required.

Application

Primer

The Concrete substrate must be primed with SILCOR® PMMA Concrete Sealer before application of the SILCOR® PMMA HG membrane with a brush or roller. Use SILCOR PMMA Metal Primer for the application on metal. Concrete Sealer or Metal Primer may be brushed or rolled onto clean and prepared substrate. Allow it to cure completely prior to SILCOR PMMA HG liquid membrane application.

Membrane;

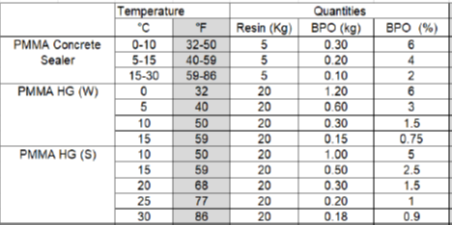

Mix SILCOR PMMA HG resin using an agitator until the liquid is uniform. Then add the SILCOR PMMA catalyst powder into resin and mix with the agitator for atleast 2-3 minutes of until powder is completely mixed into resin. Amount of catalyst powder must be adjusted according to the temperature as given in table below.

Mixed SILCOR® PMMA HG system is poured onto the substrate and spread using a trowel, brush or roller. Other methods such as notched squeegee or skid-leveler are acceptable depending upon contractor preference and substrate regularity.

For vertical surfaces, the material should be applied by brush or trowel.

SILCOR® PMMA Fabric can be used as reinforcement in flashings, turnups and field applications. Reinforcement is not required if topcoat is used. Topcoat can be DECSEAL® wearing course or additional layer of 40mil (0.51) mm of SILCOR® PMMA membrane.

SILCOR® PMMA HG can be trafficked or loaded with overburden once fully cured.

Coverage

- SILCOR® PMMA Concrete Sealer - apply 0.25 – 0.50kg/m2 , very porous substrates may require a second application.

- SILCOR® PMMA Metal Primer : apply 0.33 – 0.53kg/m2, depending on the texture of the substrate.

- SILCOR® PMMA HG membrane:

- Horizontal Application – apply single coat at 2.8kg/m2 at 2mm dry thickness or as a two-coat system of 1.4kg/m²/coat for a dry thickness of 1mm per coat

- Vertical Application - applied in two even coats of 1.4kg/m²/coat for dry film thickness of 1mm per coat to achieve a minimum dry film thickness of 2mm.

Powder Catalyst/BPO Levels

Note: SILCOR PMMA HG system is extremely rapidly cure. Excessive mixing may reduce working time of resin.

Cleaning

All tools and equipment should be cleaned with acetone before the material is allowed to cure.

Physical Properties

| Physical Property | Test Method | Typical Value |

| Peak Load @ 73.4°F (23°C) lbf/in | ASTM D5147 | 67 |

| Elongation @ 73.4°F (23°C) % | ASTM D5147 | 100 |

| Peak Load @ 73.4°F (23°C) post heat aging, lbf/in | ASTM D5147 | 82 |

| Elongation @ 73.4°F (23°C) post heat aging, % | ASTM D5147 | 135 |

| Peak Load @ 73.4°F (23°C) post acc. weathering, lbf/in | ASTM D5147 | 67 |

| Elongation @ 73.4°F (23°C) post acc. weathering, % | ASTM D5147 | 68 |

| Elongation @ 0°F (-18°C), % | ASTM D5147 | 21 |

| Tear Strength, lbf (N) | ASTM D5147 | 123 |

| Dimensional stability, % | ASTM D1204 / ASTM D5147 | PASS |

| Static puncture resistance, lbf | ASTM D5602 | PASS |

| Shore A Hardness | ASTM $2240 | 82 |

| Water absorption @ 212°F (100°C), % | ASTM D570 | 0.04 |

| Water vapor permeance, perms | ASTM E96 Proc A. | 0.29 |

| Low temperature flexibility, °F (°C) | ASTM D7264 Proc A. | PASS |

| Low temperature crack bridging | ASTM C1305 | PASS |

| Hydrostatic resistance, psi | ASTM D5385 | 100 |

| Pot Life (HA) | 15-20 min @ 68°F (20°C) |

gcpat.com | North America Customer Service: +1 (877) 423 6491

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

HYDRODUCT and PREPRUFE are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2020 GCP Applied Technologies Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 400, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-08-15

https://gcpat.com/en/solutions/products/silcor-pmma/silcor-pmma-hg-data-sheet