PERM-A-BARRIER® VPS 30 Video

Product Description

The PERM-A-BARRIER® VPS 30 (vapor permeable sheet) is a primerless, vapor permeable air and water barrier membrane consisting of a proprietary breathable carrier film with a specially designed adhesive. This unique membrane provides superior protection against the damaging effects of air and water ingress on building structures. It creates an effective barrier against air infiltration and exfiltration, which reduces associated energy loss and condensation problems through the building envelope.

The PERM-A-BARRIER® VPS 30 membrane is ideal for wall assemblies that require a breathable air barrier. It permits the diffusion of water vapor that might otherwise condense in the wall structure. The membrane is impermeable to water, enabling it to also act as a water drainage plane.

Advantages

- Wide application window - Surface and ambient temperatures at 0° F (-17.78° C) and above

- Primerless, self-adhered sheet - Reduces installation time

- NFPA 285 - Meets NFPA 285 as part of various wall assemblies

- Airtight - Protects against air passage and associated energy loss

- Vapor permeable - Minimizes moisture from being trapped in the wall cavity

- Water resistant - Resists wind-driven rain

- Controlled thickness - Factory-made sheet ensures constant, non-variable site application

- Lightweight - Allows for easy handling and installation

- Flexible - Conforms and bonds tightly to inside and outside corners following exterior building profiles

- Strong adhesion - Forms a tenacious bond to prepared construction substrates

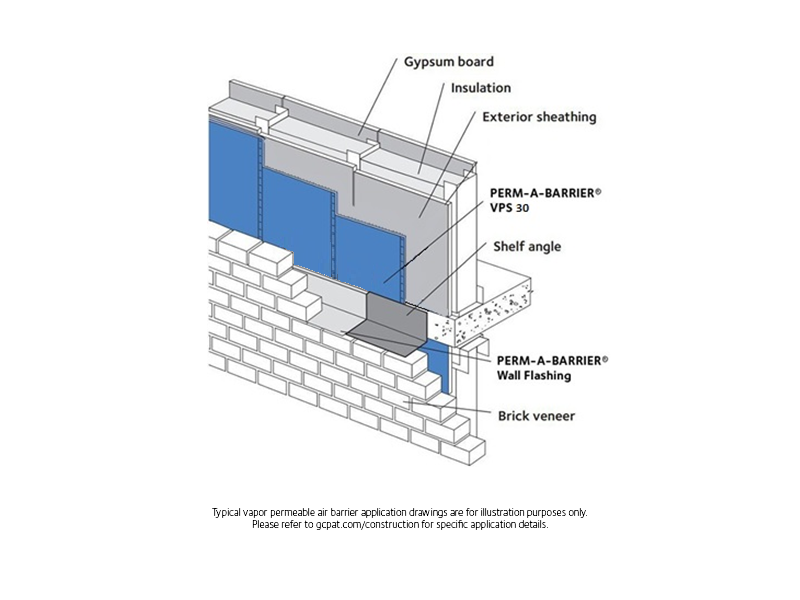

- Compatible with GCP PERM-A-BARRIER® flashing systems

- Higher Inservice temperature stability up to 200 °F (93 °C)

System Components

- PERM-A-BARRIER® VPS 30 wall membrane - Use at installation temperatures above 0° F (-17.78° C).

Ancillary Products

- PERM-A-BARRIER® S100 Sealant – For Detailing/ Liquid Flashing purposes

- PERM-A-BARRIER® NPS detail membrane - Fully adhered primerless flashing

- PERM-A-BARRIER® aluminum flashing - Aluminum faced flashing

- PERM-A-BARRIER® detail membrane - Fully adhered flashing for protecting and sealing critical detail areas

- PERM-A-BARRIER® wall flashing - Fully adhered throughwall flashing system

- BITUTHENE® liquid membrane - Two-component, elastomeric liquid and sealant applied detailing compound used for details and terminations

Limitations of Use

- Approved uses only include those specifically detailed in this product data sheet and other current product data sheets found at gcpat.com

- The PERM-A-BARRIER® VPS 30 membrane is not intended for any other use than what is found in this data sheet. Contact GCP Technical Services where any other use is anticipated or intended.

- The PERM-A-BARRIER® VPS 30 membrane must not be applied in areas where it will be permanently exposed to direct sunlight. The PERM-A-BARRIER® VPS 30 membrane must be covered within 270 (9 months) days of installation. Refer to Technical Letter 19, Exposure Guidelines for PERM-A-BARRIER® Self-Adhered Membranes, as exposure guidelines for some system components may vary.

Safety and Handling Information

Read and understand the product label and safety data sheet (SDS) for each system component. All users should acquaint themselves with this information prior to working with the products and follow the precautionary statements. SDSs can be obtained by contacting your local GCP representative or office, by calling GCP toll free at 1-866-333-3SBM (3726) and in some cases from our website at gcpat.com.

Storage

- All materials must be protected from rain and physical damage. Pallets of PERM-A-BARRIER® VPS 30 membranes must not be double stacked on the job site. Store off the ground and provide cover on top and all sides, allowing for adequate ventilation.

- Store the membranes where temperatures will not exceed 90°F (32°C) for extended periods.

- All products must be stored in a dry area away from high heat, flames or sparks.

Installation

Temperature Limitation

The PERM-A-BARRIER® VPS 30 wall membrane may be applied only when air and surface temperatures are above 0° F (-17.78° C). Maximum in-service temperature is 200 °F (93 °C).

Surface Preparation

The surface must be smooth, clean, dry to the touch and free of voids, spalled areas, loose aggregate, loose nails, sharp protrusions or other matter that might hinder the adhesion or regularity of the wall membrane installation. Clean loose dust or dirt from the surface that the wall membrane is to be applied to by wiping it with a clean, dry cloth or brush. It is best practice to apply a PERM-A-BARRIER® primer or adhesive onto any gypsum cut edge to reduce dust prior to membrane application. For OSB, it is recommended to use PERM-A-BARRIER® Adhesive Primer with a coverage rate of >450sft/gal before applying the membrane.

Membrane Application

Cut membrane into easily handled lengths. For surfaces without pre-existing, in-place penetrations (masonry anchors, ties etc.), apply the membrane horizontally or vertically to the properly prepared substrate, beginning at the base. All subsequent side and end laps must maintain a minimum overlap of 2 in. (51 mm). All horizontal laps must be applied in a shingle/water shedding configuration.

For conditions with existing masonry anchors (ties), apply the membrane horizontally to the prepared wall, beginning at the base. Each length of the membrane must be installed so that the upper edge runs continuously along the underside of the line of masonry anchors (ties). Subsequent membranes applied above must overlap the sheet below by 2 in. (51 mm) immediately below the line of anchors (ties). The membrane may be cut to an appropriate width such that it fits between the rows of anchors and allows for a min. 2 in. (51 mm) overlap onto the membrane below. It will be necessary to cut the membrane at the location of the anchors projecting from the wall to enable the sheet to be laid in place.

All slits and relief cuts made around the anchors (ties) are required to be sealed with BITUTHENE® liquid membrane, PERM-A-BARRIER® S100 Sealant or GCP approved, compatible sealant. End laps and side laps that occur in subsequent lengths that follow should maintain a minimum overlap of 2 in. (51 mm).

To prevent water from migrating under the membrane, the membrane must be rolled firmly into place with a hand roller as soon as possible, ensuring continuous and intimate contact with the substrate.

In certain applications such as on soffits or ceilings, back nail the membrane along the side lap prior to installing/overlapping the next sheet of membrane.

In these applications, additional fastening may be required through the field of the membrane, and must be sealed with BITUTHENE® liquid membrane, PERM-A-BARRIER® S100 Sealant or GCP approved sealant. Alternately, install a termination bar that spans the soffit to ensure positive contact to the substrate.

Apply BITUTHENE® liquid membrane, PERM-A-BARRIER® S100 Sealant or GCP approved, compatible sealant to seal around the anchors. Fit the PERM-A-BARRIER® VPS 30 product tightly around all penetrations through the membrane and seal using BITUTHENE® liquid membrane or GCP approved compatible sealant.

Continue applying the membrane into all openings in the wall area, such as windows, doors, etc., and terminate at points that will prevent interior visibility. The installation must be made continuous at all framed openings, such as windows, doors, etc. Flash framed openings with PERM-A-BARRIER® NPS detail membrane, PERM-A-BARRIER® aluminum flashing, or PERM-A-BARRIER® detail membrane, and overlap onto PERM-A-BARRIER® VPS 30 in a shingled water shedding manner. Coordinate installation of PERM-A-BARRIER® VPS 30 with the roofing trade to ensure continuity with the roofing system at this critical transition area.

At the end of each working day, if the wall has been only partially covered, apply a bead of BITUTHENE® liquid membrane or GCP approved, compatible sealant along the top edge of the membrane at its termination to prevent vertical drainage of precipitation from penetrating the end and undermining the membrane adhesion. Tool to ensure the sealant is worked into the surface.

Inspect the membrane before covering, and repair any punctures, damaged areas or inadequately lapped seams.

Membrane Protection

PERM-A-BARRIER® VPS 30 wall membranes must be protected from damage by other trades or construction materials. All damaged areas must be repaired.

Membrane Repairs

Repairs must be made using PERM-A-BARRIER® VPS 30 Wall Membrane sized to extend 3 in. (75mm) in all directions from the perimeter of the affected area. The repair piece must be pressed into place with a hand roller as soon as possible to ensure continuous and intimate contact with the substrate. When sealing the patch if placed in a diamond pattern both water sheading edges will need sealant. If the patches are placed straight, then the top edge and minimum of 3” down each side will need sealant termination. If the sealing patch is horizontal, then all edges will need sealant termination. To seal apply a bead of BITUTHENE® liquid membrane, PERM-A-BARRIER® S100 Sealant. To repair gaps which are less than 1/8 inch in diameter (fish mouth gaps) cover with ‘PERM-A-BARRIER® S100 Sealant’ extending 2 inches in diameter from the gap.

Supply

| Product | Unit of Sale | Size/Coverage | Weight (nominal) | Palletization |

| PERM-A-BARRIER® VPS 30 wall membrane | 1 roll | 38.5 in X 141 ft 450 ft2 per roll | 32 lbs./roll | 25 cartons (25 rolls) per pallet |

Physical Properties

| Property | PERM-A-BARRIER® VPS 30 Wall Membrane | Test Method |

| Color | White | |

| Water resistance of in-place membrane | Pass at >20 psf | ASTM E331 |

| Air permeance at test pressure of 1.57 psf (75 Pa) | < 0.02 L/s/m2 (0.004cfm/ft2) | ASTM E2178 |

| Assembly air permeance at test pressure of 1.57 psf (75 Pa) | < 0.2 L/s/m2 (0.04cfm/ft2) | ASTM E2357 |

| Water vapor permeance | 13.9 perms | ASTM E96, Method B, wet cup |

| Water resistance | Pass | ICC – AC38 |

| Water Penetration Resistance Around Nails / Fastener Sealability | Pass | AAMA 711 Section 5.2, ASTM D1970 Modified |

| Peel strength @ minimum temperature (25℉) | >1.5 lbf/in to VPS 30 | ASTM D903 modified |

| Pull adhesion | >15 psi. Gypsum board >12 psi CMU | ASTM D4541 |

| Breaking force | >40lb Machine Direction >35lb Cross Direction | ASTM D5034 |

| Low temperature flexibility | Pass | ICC – AC38 |

| Surface burning characteristics | Flame Spread Index, Class A Smoke Developed Index, Class A | ASTM E84 |

| Drainage Efficiency | 90%* | ASTM E2273 |

| Wall assembly fire test | Pass as part of various wall assemblies with foam plastic insulation | NFPA 285 |

*Please request external test report, if needed, for more details.

gcpat.com | North America Customer Service: +1 (877) 423 6491

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

BITUTHENE and PERM-A-BARRIER is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 400, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-08-04

https://gcpat.com/en/solutions/products/perm-a-barrier-vps-30-air-barrier/perm-a-barrier-vps-30-wall-membrane