Product Description

BITUTHENE® HRA is a single component, hot-applied rubberized asphalt for use on horizontal decks, planters, roofs, and other applications requiring a robust monolithic waterproofing system. It is composed of premium asphalt, synthetic rubbers, and stabilizing fillers. This blend of materials produces a compound that is very resilient, durable, and displays excellent adhesive properties.

For other HRA system products see the individual product data sheets.

Product Advantages

- Robust polyester reinforced 215 mil (5.5 mm) waterproofing system

- Meets or exceeds CAN/CGSB-37.50

- Compatible with a variety of substrates

- Fully adhered, seamless, and monolithic.

- Accommodates construction schedules - can be installed at temperatures as low as 0°F (-18°C), provided surface is clean, dry, free of ice, snow, and frost. Refer to GCP cold weather application guideline.

- Contains 100% solids

- Minimum 5% recycled content

- Use under pavers, concrete slabs, green and other overburden systems

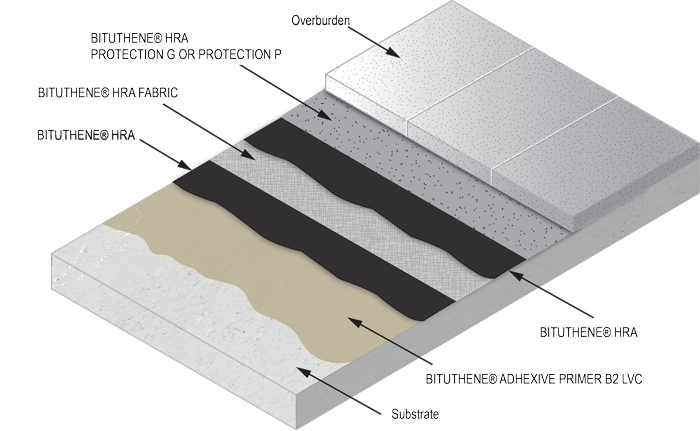

System Components

BITUTHENE® HRA – Hot Rubber Membrane

BITUTHENE® HRA FABRIC– Polyester Reinforcement

BITUTHENE® HRA NEOPRENE 12” x 100’ – Neoprene for Flashing

BITUTHENE® HRA NEOPRENE 6” x 100’ – Neoprene for Flashing

BITUTHENE® HRA PROTECTION G – Fiberglass Protection Sheet

BITUTHENE® HRA PROTECTION P – Polyester Protection Sheet

BITUTHENE® ADHESIVE PRIMER B2 LVC - Primer

BITUTHENE® HRA CAP – Cap Sheet for Wall Flashing

Packaging

BITUTHENE® HRA is supplied in 30-pound wrapped blocks which are packaged in recyclable cardboard boxes. The product and wrapping is added directly into the melter without the cardboard

Safety & Handling

BITUTHENE® products must be handled properly. Do not handle until all safety precautions and instructions have been read and understood. Refer to product label and SDS before use. SDSs can be obtained from www.gcpat.com or by contacting your local representative.

Since these products are heated to elevated temperatures, it is essential that operations be conducted safely. All personnel need to be aware of the hazards of using hot-applied materials and safety precautions. All workers should use the required Personal Protective Equipment (PPE) when working with BITUTHENE HRA. Wear safety glasses with side shields (or goggles), wear appropriate chemical resistant gloves and clothing. When handling hot material, use heat resistant gloves. Use of an impervious apron is recommended. In case of insufficient ventilation, wear suitable respiratory equipment.

If hot product gets into eyes, flush the eye with water for 15 minutes and see a physician immediately. For burns from molten product, immediately submerse the affected area in water {the cooler the better) to cool as quickly as possible. Do not use solvents to remove the product and do not peel solidified product from skin. Remove product using mineral oil, soap, and water. For severe burns, seek immediate medical attention. If inhaled, remove person from the source and assist breathing if necessary. Seek medical attention if breathing is stopped or affected. If ingested, induce vomiting.

STORAGE

BITUTHENE HRA should be stored off the ground on a dry level surface with good drainage and completely protected with a weather-resistant covering. If this covering is damaged boxes may get wet, lose strength, and crush. If using pallets for storage, do not double stack as crushing of bottom boxes may occur. Product properties are not affected by packaging deterioration. BITUTHENE HRA has a shelf life of 1 year.

Weather:

Installation of BITUTHENE HRA waterproofing system shall be undertaken only when precipitation has not occurred during the previous 48 hours and is not imminent. Recommended ambient and substrate surface temperature is 40°F (5°C) and rising, can be installed at temperatures as low as 0°F (-18°C), provided surface is clean, dry, free of ice, snow, and frost. Refer to GCP cold weather application guideline. BITUTHENE HRA is not intended to be applied on lightweight insulating concrete. For installation on structural lightweight concrete consult GCP Technical.

Equipment:

Melter: Material is to be heated in a thermostatically controlled double jacketed melter that uses oil as a heat transfer medium and is equipped with a mechanically operated agitator. Melter must be equipped with two devices that monitor both asphalt and heating oil temperature with an accuracy of ±2°C. Temperature of the hot rubber must be 380°F - 400°F (193°C - 204°C). Do not use direct heat to melt BITUTHENE HRA. A separate job site inferred thermometer with an accuracy of ±2°C must be available to verify the material temperature coming from the melter and at the point of application.

Surface Preparation:

Substrates must be structurally clean, dry, sound, smooth, free of rust, paint, and laitance and meet or exceed minimum requirements of substrate manufacturer and local codes. New concrete shall be cured not less than 14 days depending on the curing rate of the concrete. The moisture condition of the concrete surface shall be 5% or less and sufficiently dry to prevent vaporization of moisture and blistering during application of the primer and membrane. The substrate surface should meet CSP 3-5 and have a light broom or wood float finish. If curing compounds are used or contaminants are in the concrete, shot blasting may be required to prepare the surface.

All defects in concrete surfaces, cracks, delamination, and spalled areas shall be repaired with a suitable patching material and cured to the patching manufacturer’s specification. All protrusions, ridges, trowel marks and sharp edges shall be removed by grinding. Protrusions shall be blunt and not exceed 5 mm (200 mils) and depressions shall not exceed 10 mm (400 mils).

Priming:

Lightly spray or roll apply BITUTHENE® ADHESIVE PRIMER B2 LVC at a rate of 700-900 sft/gal. Allow primer to cure until dry. Do not use excess primer or let primer puddle. For details, please refer to BITUTHENE® ADHESIVE PRIMER B2 LVC data sheet.

Details:

Substrate detail work should be done prior to application of the waterproofing membrane per manufacturer’s instruction.

Waterproofing of joints, cracks, segment joints and shear keys: Apply a coat of hot BITUTHENE HRA waterproofing membrane 118 mil (3 mm) thick and 8” (203.2 mm) wide on either side of joints, cracks, or shear keys. For all filled cracks, precast segment joints, and joints with gaps less than ¼” (6.4 mm), apply a 12” (305 mm) wide piece of BITUTHENE HRA FABRIC into the hot rubber. For cracks larger than ¼” (6.4 mm) apply a 12” (305 mm) wide piece of BITUTHENE HRA NEOPRENE into the hot rubber. Consult GCP Technical for use of expansion joints for larger cracks. Overlap ends of pieces by 4” (101.6 mm) making sure adequate hot rubber is between the laps.

Penetrations, base flashings, and other similar details can be installed per GCP’s instructions before or in sequence with the primary waterproofing layer using BITUTHENE HRA FABRIC or BITUTHENE HRA NEOPRENE to reinforce the hot rubber or BITUTHENE HRA PROTECTION G as a base ply.

Application of Primary Waterproofing:

BITUTHENE HRA shall be continuously agitated until the material can be drawn free, flowing, and lump free from the melter at a temperature of 380°F-400°F (193°C-204°C). Lower temperatures may result in difficult to handle material and improper adhesion. Ensure hot rubber is fully bonded to the primed substrate.

To the primed substrate and all pre-installed detail work apply a monolithic base layer of BITUTHENE HRA at a minimum 90 mils (2.3mm) thick. Immediately embed BITUTHENE HRA FABRIC into this base layer while it is still hot, flowable, and tacky making sure to overlap the reinforcement by a minimum 2" (50.8 mm) and ensuring waterproofing is between the lap layers. Using the application squeegee or broom remove any trapped air from under the reinforcement. Apply a top layer of BITUTHENE HRA at 125 mils (3.2mm) to fully encapsulate the FABRIC within the hot rubber. While top layer is hot and tacky install a protection layer of BITUTHENE HRA PROTECTION G or BITUTHENE HRA PROTECTION P. Side laps to be 2" (50.8 mm) and end laps to be 4" (101.6 mm). If system is to be left indefinitely exposed install BITUTHENE HRA CAP in place of the protection sheet. The side laps of the cap sheet are to be 3" (76.2 mm) and end laps 6" (152.4 mm). Standard coverage rate for BITUTHENE HRA at a total of 215 mils is 1.4 lbs per 1 ft2.

Typical Property Data

| Test Description | Test Method | Values |

| Application Temperature, F | CGSB 37.50-M89 | 380° - 400°F (193° - 204°C) |

| Flow, mm @ 140°F | CGSB 37.50-M89, ASTM D5329 | 0 |

| Softening point °C | ASTM D36 | 98°C (209°F) Min |

| Adhesion rating | CGSB 37.50-M89 | pass |

| Cone penetration, 77°F | CGSB 37.50-M89, ASTM D5329 | 81 |

| Cone penetration, 122°F | CGSB 37.50-M89, ASTM D5329 | 145 |

| Toughness, joule | CGSB 37.50-M89 | 19.4 |

| Toughness ratio | CGSB 37.50-M89 | .052 |

| Adhesion rating | CGSB 37.50-M89 | pass |

| Water vapor permeance, perms (ng/Pa.m2.s) | CGSB 37.50-M89, ASTM E96-E | 1 |

| Water absorption, g | CGSB 37.50-M89 | 0.13 gain |

| Water resistance (pinhole, delamination, blistering, etc.) | CGSB 37.50-M89 | pass |

| Low temperature flexibility, -25°C (-13°F) | CGSB 37.50-M89 | pass |

| Crack bridging, -25°C (-13°F) | CGSB 37.50-M89 | pass |

| Heat stability, 5hrs | CGSB 37.50-M89 | pass |

| Viscosity at application temperature | CGSB 37.50-M89 | 4 |

| Bond to concrete, 0F | ASTM D5329 | Pass |

| Resilience | ASTM D5329 | 30% |

| Hydrostatic pressure resistance, psi | ASTM D751-A1 | 119 |

| Hydrostatic pressure resistance, 100 psi | ASTM D5385 | 100 |

| Flash point, C.O.C., F | CGSB 37.50-M89, ASTM D92 | >500°F |

| Recycled Content | 5% Minimum |

*NOTE: Published results are nominal production values confirmed by independent laboratory testing.

TECHNICAL ASSISTANCE & SERVICES

GCP provides technical assistance in the product selection, specification, and application guidelines for all GCP HRA systems. Field representatives are available for consultation in each region.

For more information, contact GCP Technical Services

gcpat.com | North America Customer Service: +1 (877) 423 6491

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

BITUTHENE is a trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 400, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-06-06

https://gcpat.com/en/solutions/products/bituthene-hra-waterproofing-system/bituthene-hra-data-sheet