Introduction

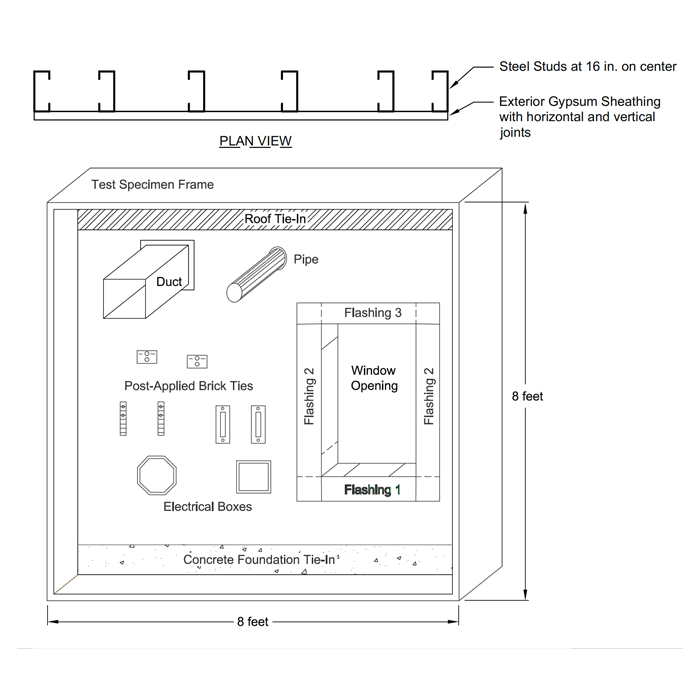

To provide proof that our air barrier assemblies function as a continuous air barrier, GCP Applied Technologies (GCP) has successfully completed independent testing on its PERM-A-BARRIER® air barrier products in accordance with ASTM E 2357 Standard Test Method for Determining Air Leakage of Air Barrier Assemblies. Testing PERM-A-BARRIER® VPL/VPL LT, PERM-A-BARRIER® NPL-10/NPL-10 LT, PERM-A-BARRIER® VPL 50 RS UV Stable, PERM-A-BARRIER® VPS 30, PERM-A-BARRIER® NPS, and PERM-A-BARRIER® Wall Membrane, the ASTM E 2357 test entails installing a full air barrier assembly onto an 8 ft by 8 ft (2.5 m by 2.5 m) mock-up of a realistic exterior wall assembly. Measuring performance simulating real-life commercial structures, the mock-up includes a tie in to a foundation wall, tie in to a roof, duct and pipe penetrants, electrical outlet penetrants, a window opening and post applied brick ties. All these conditions must be sealed and flashed to the air barrier assembly to withstand positive and negative sustained wind and wind gust loading simulating real life in place conditions.

The ASTM E 2357 Standard

The ASTM E 2357 Standard was developed to provide a uniform method to evaluate a full air barrier assembly. Until this test method was developed, one could only evaluate pieces of the air barrier assembly such as the air barrier material alone, the flashing material alone and the sealing materials alone. This method also incorporates wind loads that will push and pull on the air barrier assemblies, exposing weak areas that could leak air, which is an advancement from the previous test methods.

The Test

The mock-up is exposed to positive and negative sustained wind loading of 12.5 psf (600 Pa) for a one-hour duration in each direction. The wind gust loading reaches 25 psf (1200 Pa), which is equivalent to wind gusts of 99 mph, again in both the positive and negative direction. After all of the wind loading is completed the air barrier assembly is measured for air leakage in both the positive and negative direction.

ASTM E 2357 Test Results

GCP Applied Technologies Product Assembly Tested

PERM-A-BARRIER® VPL50 RS UV Stable

PERM-A-BARRIER® NPL-10/NPL-10 LT

PERM-A-BARRIER® VPL/VPL LT

PERM-A-BARRIER® VPS 30

PERM-A-BARRIER® NPS

PERM-A-BARRIER® Wall Membrane

1ABAA specified requirement is 0.04 cfm/ft2.

2 Air leakage rates below detectable limit of laboratory test equipment

“Air barrier products have abounded on the market place in recent years as the industry has embraced a new understanding in building construction, which itself is a rare occurrence. By providing test results utilizing ASTM E 2357 a product manufacturer can demonstrate the sufficiency of their materials when combined into an assembly that will work with the whole building system. This enables all interested parties to make informed decisions with assurance for the buildings design and sustainability. GCP is to be congratulated for their accountability in this process.”

Lance E. Robson, Jr., AIA

Building Envelope Technologies, Inc.

The Results

With test results of <0.0008 cfm/ft2 (0.004 L/s*m2), PERM-A-BARRIER® VPL/VPL LT, PERM-A-BARRIER® NPL-10/NPL-10 LT, PERM-A-BARRIER® VPL 50 RS UV Stable, PERM-A-BARRIER® VPS 30, PERM-A-BARRIER® NPS, and PERM-A-BARRIER® Wall Membrane all achieved air leakage rates below the detectable limits of the test laboratories equipment and are 50 times below the allowable air leakage rates specified by the Air Barrier Association of America (ABAA) and a proposed revision to ASHRAE 90.1 of 0.04 cfm/ft2 (0.2 L/s*m2).

PERM-A-BARRIER® Flashing was used to flash the window opening on all three mock-ups and BITUTHENE® Liquid Membrane was used in areas required by standard GCP details and recommendations, such as water bucking laps of flashing membrane and annular space around the duct, pipe and electrical box penetrants.

After successfully completing the ASTM E 2357 testing on the air barrier assemblies, GCP chose to subject the assemblies to extreme wind loading beyond the requirements of the test. The PERM-A-BARRIER® air barrier assemblies withstood the equivalent of 168 mph wind gusts, air pressures of 72 psf (3445 Pa), before allowing air leakage through the assembly. The dramatic photo below shows how the steel studs, steel fasteners and gypsum sheathing were brought to failure prior to the air barrier assembly finally giving way and allowing air leakage. This is proof positive that GCP Air Barrier Assemblies provide an air barrier solution for real life air barrier conditions.

ASTM E 2357 Test Assembly

“ASTM E 2357 is the only test method that gives the user any information on the performance of an installed air barrier assembly. Every building contains multiple air barrier materials. It is only when a material is selected and combined into an assembly does it actually perform the function of an air barrier. ASTM E 2357 determines the air leakage rate after being conditioned under real world loads which provides the user with a precise air leakage rate and confidence that it will provide this performance when installed. Data from ASTM E 2357 is critical to every design professional.”

Mr. Laverne Dalgleish

Executive Director of the Air Barrier Association of America

gcpat.com | North America Customer Service: +1 (877) 423 6491

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation or suggestion is intended for any use that would infringe any patent, copyright or other third-party right.

PERM-A-BARRIER, BITUTHENE, and RIPCORD are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies, Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies, Inc. All rights reserved.

GCP Applied Technologies Inc., 62 Whittemore Avenue, Cambridge, MA 02140, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 400, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-13

https://gcpat.com/en/solutions/products/perm-a-barrier-air-barrier-system/tl-0017-proof-air-barrier-assembly-testing