Product Description

HYDRODUCT® 225 consists of a nominal 0.4 in. (10.16 mm) drainage core, a high performance geotextile and a high strength backing film.

Uses

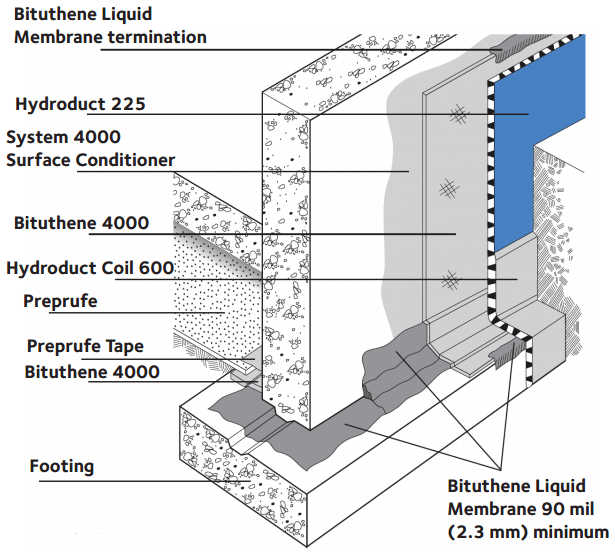

HYDRODUCT® 225 is designed to collect and transport water in hydrocarbon contaminated environments. It can be used on horizontal applications which will be exposed to hydrocarbons such as airports and parking decks. HYDRODUCT® 225 can also be used on foundation walls, retaining walls, bridge abutments, tunnels, earth sheltered structures and soil retention systems. The discharge of water collected from contaminated soil must comply with federal, state and local regulations. HYDRODUCT® 225 can also be used in conjunction with hot asphalt as a setting bed for pavers. Temperature of the asphalt during installation should not exceed 325°F (183°C). Hand tamp pavers into hot asphalt. Do not use mechanical or vibratory compactors. Discontinuous wearing surfaces such as bricks, cobblestones, etc. should be set in a minimum 3 in. (75 mm) setting bed.

Product Advantages

- Hydrocarbon resistant—suitable for contaminated environments

- Heat resistant—use below hot asphalt bedding for pavers Enhances

- waterproofing—eliminates hydrostatic pressure build-up

- Efficient water collector/deflector—can be used as a sandwich drainage layer between lagging and the reinforced concrete structure

- Smooth polymeric sheet—compatible with PREPRUFE® , PROCOR® or BITUTHENE® membranes Simple

- convenient drainage and protection layer—serves as robust membrane protection and drainage

- Geotextile fabric filter—allows ground water to pass into the drain core while restricting the movement of soil particles

- High flow capacity

Application Procedures

Safety, Storage and Handling Information

All construction products must be handled properly. Safety Data Sheets (SDS) are available and users should acquaint themselves with this information. Carefully read detailed precaution statements on product labels and the SDS before use.

Installation

In vertical applications, HYDRODUCT® 225 can be applied to the substrate vertically or horizontally but, in either case, should extend from the perimeter discharge pipe to a point approximately 6 in. (150 mm) below the anticipated grade line.

When adhering HYDRODUCT® 225 directly to BITUTHENE® waterproofing membranes, PREPRUFE® Detail Tape should be used. When using PREPRUFE® Detail Tape, press firmly to ensure good adhesion. Substrate and job site conditions will determine attachment pattern. Abut adjacent rolls with excess fabric overlapping in shingle fashion.

For inside and outside corners, abut adjoining drainage composite at the corner. Cover open core with extra geotextile filter fabric.

The exposed core along the top terminations should be covered with a strip of geotextile to prevent intrusion of soil into core. At the bottom termination extend the HYDRODUCT® 225 out from the structure so that it passes behind and under the perimeter discharge pipe. Additional geotextile should be wrapped over the pipe to prevent soil intrusion.

The exposed core along the top terminations should be covered with a strip of geotextile to prevent intrusion of soil into core. At the bottom termination extend the HYDRODUCT® 225 out from the structure so that it passes behind and under the perimeter discharge pipe. Additional geotextile should be wrapped over the pipe to prevent soil intrusion.

In horizontal applications, adhere HYDRODUCT® 225 with PREPRUFE® Detail Tape. Substrate and job site conditions will determine attachment pattern. Additional consideration should be given in high wind exposures. Abut all edges tightly with the excess geotextile placed over the adjacent roll in shingle fashion.

HYDRODUCT® 225 should be covered promptly. Do not leave HYDRODUCT® 225 exposed to sunlight for more than two weeks. Motor vehicles, construction equipment or other trades should not be allowed directly on the HYDRODUCT® 225.

Supply

| HYDRODUCT® 225 | |

|---|---|

| Roll size | 6 ft x 50 ft (1.82 m x 15.2 m) 300 ft2 (27.87 m2) |

| Packaging | 6 rolls/pallet (vertical orientation) |

| Weight | 80 lbs (36.28 kg)/roll |

| Complimentary Materials | |

| PREPRUFE® Detail Tape | 2 in. x 50 ft (50 mm x 15 m) roll/16 rolls per carton |

Physical Properties

| PROPERTY | TYPICAL VALUE | TEST METHOD |

|---|---|---|

| Drainage Core | ||

| Thickness | 0.4 in. (10 mm) nominal | ASTM D-1777 |

| Compressive strength | 21,000 lbs/ft2 (1000 kPa) | ASTM D6364 |

| Flow rate (gradient 1.0) | 21 gal/min./ft (260 L/min./m) | ASTM D4716 |

| Geotextile | ||

| Tensile strength | 365 lbs (1,624 kN) | ASTM D4632 |

| Apparent opening size | 40 U.S. sieve (0.42 mm) | ASTM D4751 |

| Flow rate | 145 gal/min./ft2 (5909 L/min./m2) | ASTM D4491 |

| CBR puncture | 675 lbs (3.04 kN) | ASTM D6241 |

gcpat.com | North America Customer Service: +1 (877) 423 6491

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

HYDRODUCT, PREPRUFE, PROCOR, and BITUTHENE are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies, Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2021 GCP Applied Technologies, Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 400, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-13

https://gcpat.com/en/solutions/products/hydroduct-drainage-composite/hydroduct-225