Microtrenching, a less-invasive, quicker means for bringing broadband connectivity than traditional methods, unfolds in a linear process during application. Let's break it down.

The microtrencher

The first step in a microtrenching job calls for shallow saw cuts along the roadside or sidewalk. This work is usually handled by a microtrencher. A microtrencher will cleanly slice through asphalt or concrete to create the micro-trench in one quick, efficient pass. The trench dimensions range from about 0.5-2 inches in width, and at a maximum depth of two feet.

Good microtrenchers will also include a vacuum excavator to handle dry, dusty spoils. This leaves the microtrench clean and clear for the next component.

The protective duct

Once the micro-trench is cut, the next step is placing conduit to house and protect the fiber optic cable. Dura-Line’s FuturePath Flex oversheath is a perfect solution, with its flat configuration and ease of pathway segregation. The user can choose a product design of up to eight MicroDucts, which are bundled and connected by an oversheath and a tangential partitioned web.

Fiber optic cable

The fiber optic cables are the main driver for microtrenching. The cables proliferate broadband connectivity from a central telecommunications provider like Verizon or Google, into many homes, businesses and government agencies. The data boom in recent decades has created increased demand for microtrenching.

Microtrenching infill

Finally, as the fiber optic cables are now secured within tough micro-ducts and nestled in a cleanly cut microtrench, it's now time to apply the final microtrenching component: The infill.

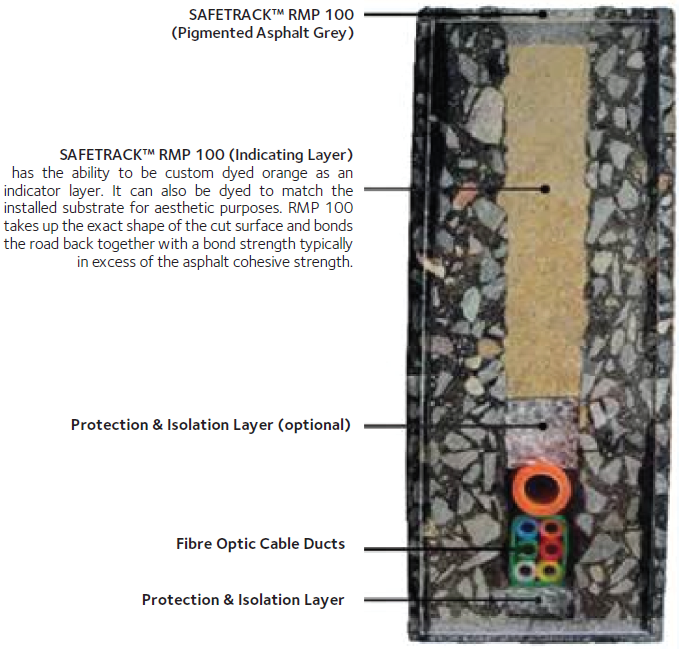

SAFETRACK™ RMP 100 microtrench infill system provides a two-tiered approach that is specifically designed for microtrenching. The first layer, an indicating layer, is cold-applied, and can be dyed bright orange for easy location, should the road require future work down the line.

SAFETRACK™ RMP 100 microtrench infill system self-consolidates and takes the shape of its microtrench. Its fast cure and unique ESSELAC™ bonding technology make it ideal for microtrenching infill. It's flexible, yet strong enough to withstand roadway compression and freeze-thaw cycles. It cures extremely fast for quick application with minimal traffic interruption. And its unique ESSELAC™ technology creates a bond stronger than the original asphalt it replaces.

The SAFETRACK™ RMP 100 infill system then caps off with a second poured layer, pigmented to match the road it reinstates. The result is a seamless installation, with minimal invasion to the existing road and drastically reduced congestion, which is especially advantageous in urban environments where non-disruptive roadwork is most desirable.

Learn more about microtrenching and SAFETRACK™ RMP 100 microtrench infill system

Tags

- Contractor

- Distributor

- Infrastructure

- Mass transit

- Road Maintenance

- SAFETRACK

- Subcontractor

- Transportation Infrastructure