Product Description

SILCOR® 900MP waterproofing is a premium performance, two-component, spray-applied, seamless waterproofing membrane that cures within two minutes to form a high-strength, elastomeric, and fully-bonded waterproof membrane. SILCOR® 900MP waterproofing is extremely durable, with excellent wear and chemical resistance, and does not normally require additional protection against mechanical damage.

Product Advantages

- Fast Cure –Accepts foot traffic after two minutes.

- Seamless – Continuous waterproofing integrity.

- Productivity – Spray-applied for maximum coverage per day.

- Fully bonded – Resists water tracking beneath the membrane.

- Non-flammable– Low VOC.

- Low Odor

- Elastomeric – Accommodates movement and bridges concrete shrinkage cracking.

- Durable – Tough, with excellent wear and damage resistance.

- Chemical Resistance

- NSF Certified (Drinking Water System Components Certification) – SILCOR® 900MP is certified for use with SILCOR® Primer EPF in accordance with NSF/ANSI/CAN 61.

- UL Certified Underwriter’s Laboratory (UL) Classification for various assemblies under TGFU.R7910

Principal Applications

New and remedial waterproofing for:

- Plaza decks

- Split slabs

- Green roofs

- Planters

- PRMA

Design

The SILCOR® 900MP spray-applied waterproofing system is designed for use as a fully adhered waterproofing layer on new and existing elevated structural decks including water retention tanks. SILCOR® 900MP can be applied on structural decks with no slope (flat deck waterproofing application). For flat deck waterproofing, it is considered best practice to incorporate proper drainage provisions alongside the SILCOR® 900MP application. A proper drainage approach further enhances the overall durability and functionality of the waterproofing system, mitigating the risk of water pooling and potential damage to the structural elements.

System Components

- SILCOR® 900MP – Premium performance, two-component, spray-applied seamless waterproofing membrane.

- SILCOR® Primer EPF – Two-component epoxy primer (for temperatures 40°F-80°F).

- BITUTHENE® Liquid Membrane – Two-component elastomeric, liquid-applied detailing accessory.

- PREPRUFE® Tape – Reinforced, pressure-sensitive tapes for detailing.

Installation

SILCOR® 900MP liquid waterproofing should be applied by experienced, trained contractors. Effective liquid waterproofing application starts with a good surface preparation of the substrate.

Surface Preparation

All grease, curing agents, oils, or other contaminants that can affect adhesion of the membrane to the surface need to be removed prior to application. Grease, dirt, and grime can be removed using high-pressure water cleaning, provided sufficient time is allowed for the residual humidity and water to dissipate before application. Sandblasting is not effective on contaminated concrete. After cleaning, the surface needs to be prepared to open the pores and make the surface ready to accept the primer. The preferred and most common method is sand or grit blasting.

Concrete must be allowed to cure for at least 28 days. Concrete should have at least an 115 psi cohesive strength. Concrete surface moisture content must be less than 5% prior to application of SILCOR® primers. Moisture content must be checked using appropriate meters and test methods.

Priming

Priming should be completed prior to applying SILCOR® 900MP.

- Add the complete B-component to the A-component to ensure a correct mixing ratio.

- Mix with a slow turning mixer (less than 300 rpm) for three minutes in order to obtain a homogeneous mixture.

- Apply primers to the surface by brush or roller, immediately after mixing.

- Pour the primer onto the surface in a zigzag pattern.

- After pouring onto the surface, the primer shall be evenly distributed onto the surface with foam rubber squeegees and rolled using Perlon rollers.

- The primer shall be evenly distributed at 10-mils thickness with complete coverage of the surface. If the surface is very porous and absorbs primer to the extent that the primer is less than 10-mils thick, additional primer should be added in this area within the pot life or recoat time of the primer. Heat is generated when components A and B are mixed. Care should be taken if excess material is left in the mixing container and not distributed onto the surface.

- The SILCOR® membrane shall be applied after initial primer curing but within 24-hours. This window is influenced by ambient temperature and humidity. If this time is exceeded before the membrane is applied, re-apply a new layer of SILCOR® primer.

For complete descriptions and instructions on using SILCOR® primers, consult separate technical data sheets.

Spray Equipment and Temperature

SILCOR® membranes are rapid setting, high performance materials designed to be used with high-pressure proportioners such as Graco® Reactor E-XP2, H-XP2, and H-XP3 or similar high-pressure plural component spraying equipment. Both Part A and Part B components are supplied directly from drums with diaphragm or T-pumps, ensuring a continuous flow of material to the machine. Due to the high reactivity of the system, components are kept separately until they reach the spray gun mixing chamber. The components are designed for a 1:1 mixing ratio by volume. The 1:1 volume mixing ratio shall be maintained at a tolerance of +/- 2%. See your equipment manufacturer for appropriate air compressor and electrical power specifications and settings.

Substrate temperature should be between 40°F and 175°F and exceed the dew point temperature by a minimum of 5°F. Can be installed down to 20°F. Please contact GCP’s Technical Service when installation below 40°F is anticipated.

SILCOR® resin (Part B) components are pigmented and need to be mixed before application with an air driven corkscrew-type mixer or similar. Mix at low speed to avoid air entrapment until a homogeneous color is obtained. After mixing, keep the Part B component agitated using a slow turning mixer in the drum during spray application using the 3-bung lid. SILCOR® isocyanate (Part A) components are supplied ready to use and do not need pre-mixing.

Both Part A and B are moisture-sensitive and need to be protected from all sources of moisture.

SILCOR® 900MP Spray Application

SILCOR® membranes are sprayed multi-directionally (up-down / left right) in several passes to obtain uniform coverage and membrane thickness. The spray gun is held perpendicularly to the substrate at a distance of 24 to 36 inches. When applying, care is required at the overlap to ensure even coverage of the overlap area. Spray-applied SILCOR® membranes should be applied at a minimum thickness of 80-mils. In order to achieve uniform membrane thickness, a smooth and constant gun speed is required by the gun operator.

Laps

When applying the SILCOR® membrane over previously installed and cured SILCOR® membrane, wait 24 hours before application. Abrade using mechanical means (a minimum of 6 inches) onto the existing SILCOR®, solvent wipe the abraded area, and lap the new SILCOR® membrane over the area. When a visible color change after exposure has occurred, a level of mechanical abrasion is required to reveal the original color of the SILCOR® membrane prior to solvent wiping and lapping the new SILCOR® membrane.

Repairs

Any damaged or unbonded SILCOR® membrane should be removed to expose the original substrate and SILCOR® primer. The existing SILCOR® membrane should be abraded at a minimum 6 inches past the damaged area in all directions, including any SILCOR® primer that is remaining on the exposed substrate. Abrading must reveal the original color of the SILCOR® membrane. Solvent wipe the prepared areas and apply SILCOR® primer only to exposed portions of the substrate. After the SILCOR® primer cures, clean the surrounding abraded SILCOR® membrane with solvent and immediately after flash off of solvent, installation of the new SILCOR® membrane shall occur, ensuring it extends a minimum of 6 inches onto the abraded, pre-existing SILCOR® membrane. It is recommended that the perimeter of the repair area be taped off to provide a clean termination at the required 80-mil thickness.

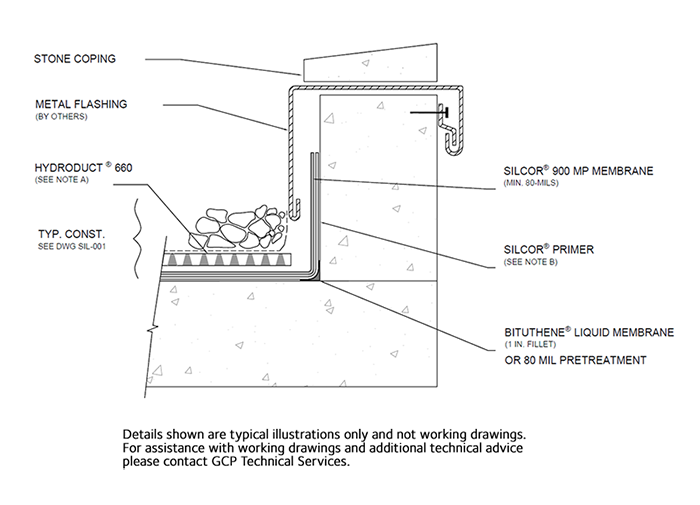

Detailing

For complete detailing instructions, refer to SILCOR® 900MP standard details.

Drinking Water System Components Certification

SILCOR® 900MP is certified for use with SILCOR® Primer EPF in accordance with NSF/ANSI/CAN 61 when installed in a tank (min. 500 gallons) with a maximum dry film thickness of 80 mils per coat.

Limitations

Apply SILCOR® 900MP directly to structural surfaces. Do not apply SILCOR® 900MP over lightweight insulating concrete. Insulation, if used, must be installed over the membrane.

The SILCOR® membrane is not intended for permanent exposure. SILCOR® 900MP liquid waterproofing, at recommended thickness, can be exposed for a maximum of 180-days prior to overburden installation. If exposure time is expected to exceed the recommended duration, the SILCOR® membrane must be temporarily protected until overburden is installed.

SILCOR® 900HA should not be used with SILCOR® 900MP. If repairs to SILCOR® 900MP cannot be completed with SILCOR® 900MP, please contact your local GCP technical representative.

Safety and Handling

Read and understand the product label and safety data sheet (SDS) for each system component. All users should acquaint themselves with this information prior to working with the products and follow the precautionary statements.

Supply

| UNIT OF SALE | |

|---|---|

| SILCOR® 900MP (resin) | 400 lb - 55 gal drum |

| SILCOR® 900MP (iso) | 495 lb - 55 gal drum |

| SILCOR® Primer EPF (Part A) | 7.1 lbs pail - approx. 0.7 gal |

| SILCOR® Primer EPF (Part B) | 4.0 lbs pail - approx. 0.5 gal |

| Storage | Store between 40°F & 80°F |

| Shelf Life - SILCOR® 900MP | 12 months |

Physical Properties

| TYPICAL VALUE | TEST METHOD | |

|---|---|---|

| Tensile Strength | 4090 psi | ASTM D412 |

| Tear Resistance | 487 lb/in. | ASTM D751 |

| Adhesion to Concrete | 479 psi1 | ASTM D4541 |

| Low Temperature Crack Bridging | Pass | ASTM C836 |

| Shore Hardness | 91A | ASTM 2240 |

Footnotes:

1. Tested on prepared, primed, and sand blended concrete or steel.

2. H18/1000 cycles/1000g

Liquid Properties

| TYPICAL VALUE | TEST METHOD | |

|---|---|---|

| Viscosity - Resin | 400-600 cps1 | Brookfield Viscometer |

| Viscosity - Iso | 800-1200 cps1 | Brookfield Viscometer |

| Density (Resin, Iso) | 8.6 lb/gal 9.2 lb/gal |

ASTM D4541 |

| Coverage Rate (80 mil thickness) | 16.4 ft2/gal 1800 ft2/kit |

internal |

| Gel Time | 5 sec1 | internal |

| Tack Free Time | 8 sec1 | internal |

| Trafficable (foot traffic) | 2 mins1 | internal |

Footnotes:

1. Measured at 77ºF

All declared values shown in this data sheet are based on test results determined under laboratory conditions and with the product sample taken directly from stock in its original packing without any alteration or modification of its component parts.

gcpat.com | North America Customer Service: +1 (877) 423 6491

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

ADCOR, PREPRUFE, PROCOR, and BITUTHENE are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2021 GCP Applied Technologies Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 400, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-13

https://gcpat.com/en/solutions/products/silcor-900-series-liquid-waterproofing/silcor-900mp