Product Description

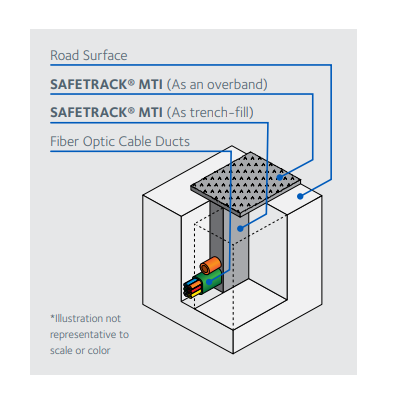

SAFETRACK® MTI is a cold-applied, liquid reinstatement system engineered for rapid, reliable infill of micro-trenches in asphalt and concrete surfaces. Powered by GCP’s proprietary ESSELAC® resin technology, it delivers fast cure times, exceptional flexibility, and seamless integration with existing roadways.

Use

Designed for reinstating micro-trenches in both asphalt and concrete, SAFETRACK® MTI provides clean termination and prevents water ingress. Its self-consolidating formulation eliminates the need for compaction, ensuring a durable, watertight seal.

Surface Preperation

Ensure trench walls and adjacent surfaces are clean and dry. Use a stiff brush followed by oil-free compressed air to remove debris and moisture. Dry thoroughly using a SAFETRACK® drying lance or compressed air, focusing on trench faces for optimal adhesion.

Product Advantages

- Rapid cure for fast return to service

- Cold-applied—no hot trades required

- Self-consolidating—no compaction needed

- Excellent mechanical interlock

- Resists deformation under traffic loads

- Available in asphalt gray, neutral, or custom colors including an orange dig-safe indicator layer

Application Equipment

SAFETRACK® MTI can be easily applied by hand or by pump. Please contact your GCP representative for details.

GCP's SAFETRACK® 200 Pump Applicator

Application

GCP provides comprehensive application training. Follow the detailed 'Application Guidelines' available to Authorized Contractors or upon request.

Coverage

Theoretical yield: 0.134 cubic feet per US gallon. Approximate yield per pail with standard BPO Catalyst (hardener powder or liquid): 3.6 US gallons. Actual coverage may vary based on site conditions and waste.

SAFETRACK® MTI Application

Temperature Range1 23 to 120°F

| Temperature2 /Substrate | Typical Working Life | Typical Cure Time3 |

|---|---|---|

| 95°F | 7 minutes | 10 minutes |

| 86°F | 10 minutes | 20 minutes |

| 77°F | 13 minutes | 35 minutes |

| 68°F | 15 minutes | 50 minutes |

| 59°F | 12 minutes* | 40 minutes* |

* Based on the use of extra hardener powder. Please contact your local GCP

representative for advice.

1. For temperatures outside this application range please contact your local

GCP representative.

2. Based on material and substrate having similar temperatures.

3. SAFETRACK® MTI can be overlaid with SAFETRACK® MTI before it is fully cured.

Overcoating

SAFETRACK® MTI can be overlaid with a second pass once the initial cure of the indicator layer is complete. No maximum overlay time—material chemically bonds to existing layers. Ensure surfaces are clean and dry before overlay.

Color

Standard: Asphalt Gray, Neutral

Optional: Orange (dig-safe indicator layer), Custom colors available on request

Cleaning

All tools and equipment should be cleaned with acetone after use, before the material is allowed to cure.

Packaging & Storage

Resin: 3.57 Gallon pail

BPO Hardener Powder: Various pack sizes

BPO Liquid Hardener: 5 Gallon Pail

Store all components in cool, dry conditions away from direct sunlight. Maximum storage temperature: 77°F (25°C). Avoid storing near open flames or food. Shelf life: Resin and BPO liquid—12 months; BPO powder—6 months.

Health & Safety

Refer to Safety Data Sheets (SDS) for each component and cleaning material prior to use. Follow all safety guidelines.

General Information

SAFETRACK® MTI is part of GCP’s portfolio of advanced highway maintenance and repair solutions. For more information, visit gcpat.com or contact your GCP representative.

gcpat.com | North America Customer Service: +1 (877) 423 6491

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

GCP APPLIED TECHNOLOGIES and SAFETRACK are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2023 GCP Applied Technologies Inc. All rights reserved.

GCP0083 STL-001-0618

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 400, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-09-23

https://gcpat.com/en/solutions/products/safetrack-mti-road-reinstatement/safetrack-mti-data-sheet