Product Description

PREPRUFE® Liquid Flashing is a two-component elastomeric, cold applied, trowel grade material designed for use with PREPRUFE® waterproofing membranes in pre-applied waterproofing systems. The VOC (volatile organic compound) content is 3 grams per liter.

The two parts of PREPRUFE® Liquid Flashing are mixed on site and troweled on to provide a simple, quick, and fully bonded waterproofing detailing aid in conjunction with PREPRUFE® waterproofing systems.

Product Advantages

- Bonds to poured concrete – Advanced Bond Technology™ maintains unique fully bonded performance

- Liquid applied – conforms to irregular profiles

- Cold applied – no flame hazard or special equipment needed

- Waterproof – resistant to water pressure

- Chemically cured – good through cure in thick applications

- System compatible – complements PREPRUFE® waterproofing system

- Reduced labor – simplifies detailing by reducing steps and materials

Use

PREPRUFE® Liquid Flashing is ideally suited for the following uses:

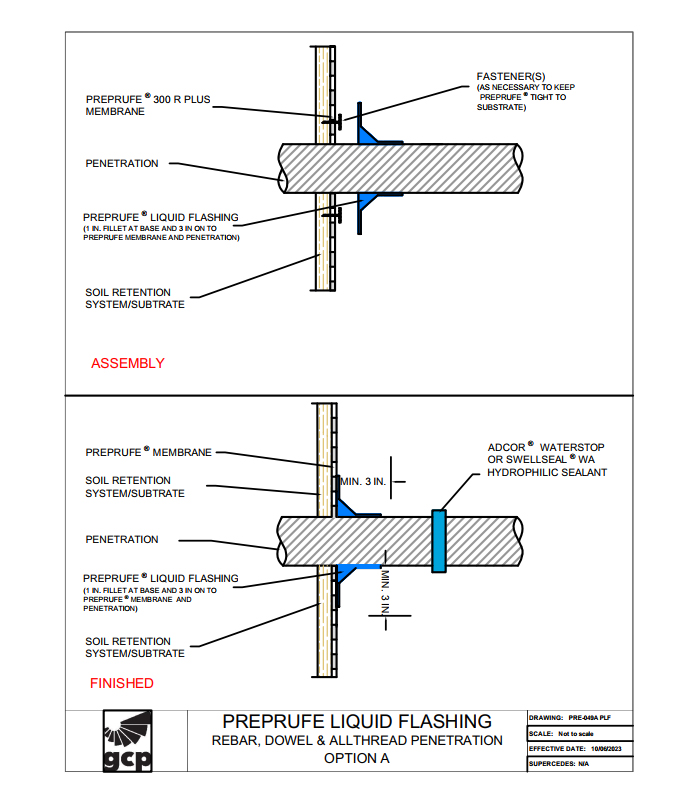

- Fillet material around pipe or rebar penetrations

- Sealing material at H-piles, columns, and terminations

- Damage repair for PREPRUFE® surface

The two parts of PREPRUFE® Liquid Flashing are mixed on site and troweled on to provide a simple, quick, and fully bonded waterproofing detailing aid in conjunction with PREPRUFE® waterproofing systems.

Physical Properties

| Module | Typical Value | Test Method |

|---|---|---|

| Part A Color | Blue | - |

| Part B Color | Clear | - |

| Mixture of Parts A and B Color | Blue | - |

| Application Temperature | 25°F to 104°F | - |

| Pot life | 45 minutes | |

| Elongation | 1000% | ASTM D412 |

| Low temperature flexibility | Unaffected at -20°F (-29°C) | ASTM D1970 |

| Crack cycling | Pass | ASTM C1305 |

| Resistance to hydrostatic head, functional details | 231 ft (71 m) | ASTM D53851 |

| Lateral Water Migration Resistance | 231 ft (71 m) | ASTM D53852 |

| Peel adhesion to post-cast concrete | 10 lbs/in. (1750 N/m) | ASTM D9033 |

| Peel Adhesion, Concrete | 10 lbs/in. (1750 N/m) | ASTM D9034 |

| Peel Strength, Steel | 10 lbs/in. (1750 N/m) | ASTM D9034 |

| Peel Strength, PVC | 10 lbs/in. (1750 N/m) | ASTM D9034 |

| Peel adhesion to PREPRUFE® Grout EG 75 | 10 lbs/in. (1750 N/m) | ASTM D9034 |

| Peel adhesion to PREPRUFE® Plus membrane | 10 lbs/in. (1750 N/m) | ASTM D18764 |

| Peel adhesion to PREPRUFE® SCS membrane | 10 lbs/in. (1750 N/m) | ASTM D18764 |

| Peel adhesion to BITUTHENE® Liquid Membrane | 10 lbs/in. (1750 N/m) | ASTM D18764 |

| Environmental Stress Resistance | Pass | ASTM D1693 |

2. Lateral water migration resistance is tested by casting concrete against membrane with a hole and subjecting the membrane to hydrostatic head pressure with water. The test measures the resistance of lateral water migration between the concrete and the membrane.

3. Sample is prepared by casting concrete against cured membrane.

4. Tested at crosshead speed of 2 inches per minute using Bituthene B2 LVC Primer over EG 75

Application Procedures

Safety, Storage and Handling Information

Safety Data Sheets (SDS) are available on request. Carefully read detailed precaution statements on product labels and the SDS before use.

Surface Preparation

Substrates should be dry and free from surface condensation or standing water. All surfaces should be clean and free from dust, dirt, site debris, grease and any other contaminants that may compromise adequate adhesion.

For concrete, prime with BITUTHENE® Adhesive Primer B2 LVC. For steel, rust and mill scale should be removed by wire brush or grinding, followed by solvent wipe. PVC surfaces should be wiped free of any debris.

Mixing and Installation

Add the entire contents of the Part B container to Part A and mix for 3 to 5 minutes using a low shear mixer until uniform, being careful to avoid trapping air in the mix. Part A is blue and Part B is clear. Take care to scrape material from the side and bottom of the containers to ensure thorough mixing. Do not apply any material if streaks or chunks can be seen due to insufficient mixing. Once mixed, PREPRUFE® Liquid Flashing must be applied by trowel within 45 minutes at 70°F. More time is available at lower temperatures.

PREPRUFE® Liquid Flashing may be applied at temperatures of as low as 25°F (-5°C). During cold weather installation less than 40°F (5°C), product must be stored above 50°F (10°C) for a minimum of 24 hours prior to application to improve workability and overall product installation. At high temperatures, thickening and curing will be faster. Material that has thickened must be discarded. The material will cure to a slightly tacky, very flexible, rubber-like material.

PREPRUFE® Liquid Flashing must be applied at a target thickness of 80 mil minimum for optimized application performance. Use a wet film thickness gauge to ensure the minimum thickness has been achieved. In fillet applications, the face of the fillet should be a minimum of ¾ in. (20 mm). PREPRUFE® Liquid Flashing will adhere to primed concrete, steel, PVC, epoxy grout, and PREPRUFE® membranes.

PREPRUFE® Liquid Flashing will remain tacky. Prior to casting concrete inspect cured PREPRUFE® Liquid Flashing for adhered trash or contamination and remove where applicable. Excessive debris build up on the membrane should be washed clean. Light power washing will not damage the membrane. Normal construction site debris, dust, etc. will not compromise the fully bonded performance of the applied membrane. Ponding water should be removed prior to concrete pour. Follow QA/QC procedure as prescribed by GCP Technical Services applicable to below grade waterproofing products like but not limited to PREPRUFE® Liquid Flashing and BITUTHENE® Liquid Membrane. Do not install if rain is imminent. 3hrs after the application light rain does not compromise the performance of PREPRUFE® Liquid Flashing. Allow PREPRUFE® Liquid Flashing to cure for 24 hrs before concrete pour.

Coverage

Preprufe Liquid Flashing minimum required thickness is 80mils (2mm), ¾’’ to 1’’ for the fillet face with 3’’ extension on both sides.

Coverage for fillet & extension material - 1 gal (3.8 L) kit will cover approximately 15 linear feet (4.6 m).

Coverage when used as flashing material - 1 gal (3.8 L) kit will cover approximately 20 ft2 (1.88 m2).

Damage Repair

Damaged PREPRUFE® Liquid Flashing can be repaired using PREPRUFE® Liquid Flashing. Fully or partially cured PREPRUFE® Liquid Flashing can be repaired using fresh PREPRUFE® Liquid Flashing which will bond very well to already applied PREPRUFE® Liquid Flashing. The PREPRUFE® Liquid Flashing that needs repairing needs to be cleaned of debris.

PREPRUFE® Liquid Flashing can be used to repair damaged surface of PREPRUFE® Plus membranes and punctures less than ½” diameter. Applied PREPRUFE® Liquid Flashing for repair should extend beyond damaged membrane 4” in all directions. For punctures larger than ½” diameter, use PREPRUFE® Tape and/or PREPRUFE® membrane patch per standard application guidelines.

UV Protection

PREPRUFE® Liquid Flashing is not designed for permanently exposed applications, it should be covered within 56 days of application.

Equipment Cleaning

Clean tools and equipment with acetone before PREPRUFE® Liquid Flashing has cured. Acetone is a combustible liquid and should be used only in accordance with the manufacturer’s safety recommendations. Do not use solvents to clean hands or skin.

gcpat.com | North America Customer Service: +1 (877) 423 6491

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

GCP, and PREPRUFE® are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2023 GCP Applied Technologies Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 400, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-13

https://gcpat.com/en/solutions/products/preprufe-liquid-flashing/preprufe-liquid-flashing-data-sheet