Introduction

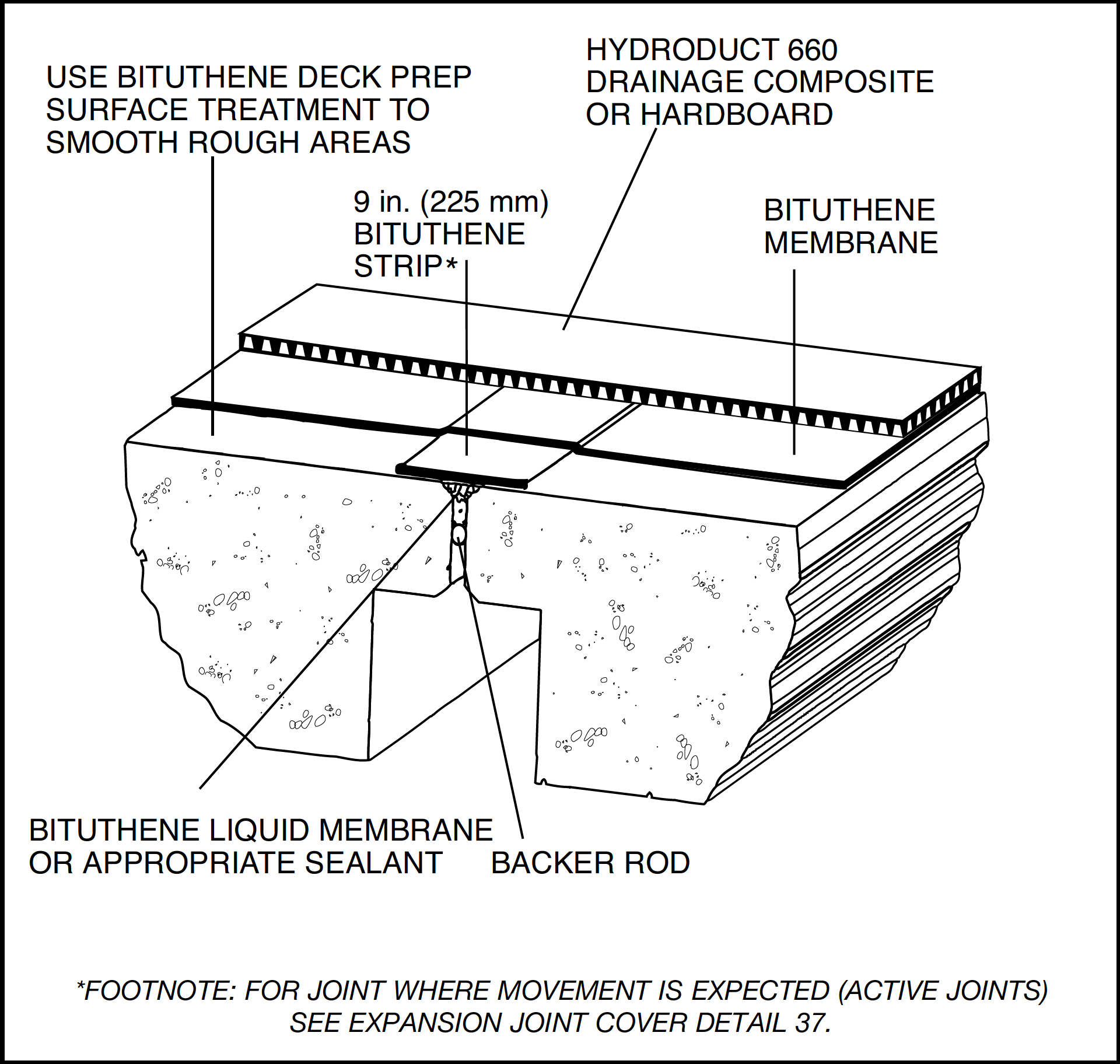

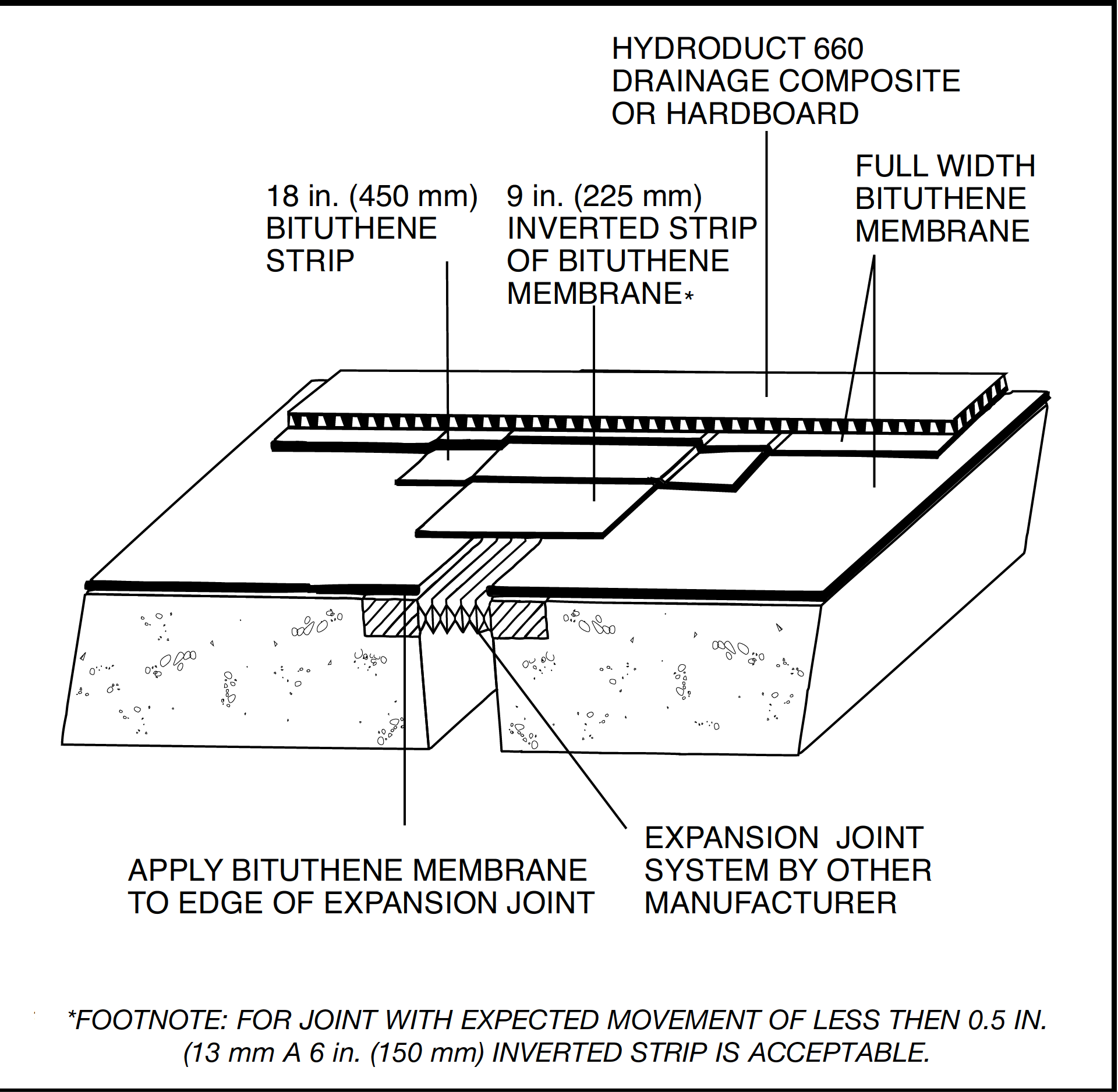

Adequately waterproofing expansion joints requires the use of materials specifically designed to do that job. PREPRUFE® and BITUTHENE® Membranes are not intended to take the place of an expansion joint system, fillers, or sealants which will allow for dynamic and differential movement between structural components. It is essential to first select a system for your expansion joints that is rated for the hydrostatic condition, joint width, and expected movement. A properly selected expansion joint system is the primary line of defense against water infiltration at the joint. The PREPRUFE® and BITUTHENE® waterproofing systems can, in most cases, be tied into expansion joint waterproofing and/ or covering systems to provide full waterproofing protection on a project. In limited situations, BITUTHENE® membranes may be used as a passive joint cover and expansion joint cover as shown in Figures 1 and 2.

Project designers and/or contractors should consult with expansion joint sealant and covering manufacturers for design and installation details. A partial listing of manufacturers is included at the end of this technical letter. Also, Section 05800 of Sweets, “Expansion Control”, and Section 07900, “Joint Sealers”, provide information on manufacturers and design possibilities.

Designers should consider using gutters under critical expansion joints to provide a second line of defense against seal failure.

Use of BITUTHENE® Membrane as an Expansion Joint Cover

Figures 1(See detail BIT-022 for guidance) and 2(see detail BIT-024 for guidance) illustrate the use of BITUTHENE® membrane as an expansion cover.

Types of Expansion Joint Sealing Systems

Most expansion joint sealing systems fall into one of four main types, and the principles of tie-in with any of these systems is determined by overall job design as much as anything else.

Surface Systems

“Bellows” Joint Seal

An example of this type is the Expand-O-Flash® family of products made by Manville (05800/MAN). Tie-in with the Bituthene® waterproofing membrane installation is done by overlapping the two systems along the flanges of the joint cover assembly. Care must be taken to assure compatibility of the systems before installation. Whenever possible, it is recommended that the flanges be “sandwiched” between two layers of Bituthene® membrane.

Sealing Strip

This consists of flat, rubber material which may be embedded into the structural concrete in various ways. Compatibility with the components must be determined. Products of this type are produced by such firms as Situra, Sika Corp. and Watson Bowman Associates, Inc.

Compression Systems

Compression sealing systems are designed to be installed into a joint in a compressed, or squeezed configuration and then be available to expand or compress to accommodate the joint. The pressure exerted by the compressed seal against the sides of the joint is responsible, at least in part, for preventing water from passing through the joint. Some systems rely entirely on pressure to keep the seal in place, others have mechanical anchoring systems, or may be glued in place by epoxy, or other sophisticated adhesives. Examples of this type of system are manufactured by Watson Bowman Associates, Inc. (05800/WAR) which have performed, extruded, internal webbed systems. Tie-in with a Bituthene® waterproofing membrane installation requires termination of the membrane, using Bituthene® Liquid Membrane, along the edge of the joint immediately next to the compression seal material. Use of a metal joint nosing, when possible, can give a higher degree of assurance for both the joint sealant and the waterproofing system.

Poured or Gunned Sealants

Another type of joint sealant system is the poured-in-place or gunned-in-place flexible joint sealant. These may be two component products conforming to Federal Specification TT-S-00227E, or single component materials conforming to Federal Specification TT-S-00230C. Sealants are made to perform at various joint movement levels. Recommended types are urethanes or silicones.

Polysulfide sealants should never be used in contact with Bituthene® membrane.

Some form of joint filler and/or backer-rod is required to prevent these materials from flowing too far into the joint, and to prevent the sealant from adhering to the bottom of the joint. Also, there are guidelines, established by manufacturers, for depth-to-width ratios and movement capabilities for most of these products. All of these do affect the waterproofing capability of these systems and should be thoroughly reviewed by the designer before installation.

Armored Joint Assemblies

These are by far the most complex and costly joint sealing systems, and are capable of withstanding the greatest amounts of movement and load. There are different designs in this group, but the major differences come in the expansion-contraction movement compensation mechanism. Most are fairly similar in their nosing and anchoring design.

Joints Used With Blindside/Pre-applied Waterproofing

Joints that can accomodate a tie in to a blindside waterproofing membrane typically consist of a flanged system. Examples of this type of joint is the Emseal BG System or Situra FlameLINE®. Preprufe® and Bituthene® membranes can be successfully tied into these systems. Due to the increased risk involved in waterproofing below grade joints in a hydrostatic condition, contact the expansion joint system manufacturer for proper joint selection and GCP for specific detail requirements for the selected system.

Conclusion

To properly design and specify the most appropriate expansion joint sealing system, several issues must be considered:

- Joint spacing

- Joint size

- Joint movement

- Compatibility of seal components with Preprufe® and Bituthene® waterproofing membranes

- Safety. Because expansion joints will be in a neutral position at certain times of the year, allowance must be made for sealing joints in a closed position in the summer and an open position during the winter

This technical letter is provided only as a guide to designing and specifying expansion joint sealing systems. Seal manufacturers must be consulted for specific design assistance.

Terms

Expansion Joint — An opening or gap between adjacent parts of a building structure or concrete work which allows for safe and inconsequential relative movement of those parts, as caused by thermal variations or other conditions.

Expansion Joint Cover — A protective cover placed over, and spanning, a joint. May be prefabricated or field fabricated. Designed to flex with the movements of the joint without loss of protection to the joint.

Expansion Joint Filler — A compressible material used to fill a joint to prevent the infiltration of debris and to provide support for sealants.

Expansion Joint Sealant — A compressible material used to exclude water and solid foreign materials from joints.

Backer Rod or Back-up — Any material or substance, placed into a joint to be sealed, to reduce its depth and/or to inhibit sagging of the sealant.

| Bellow Type Seals | Compression Seals |

|---|---|

| The D. S. Brown Co. www.arcat.com | Willseal www.willseal.com |

| EMSEAL Joint Systems Ltd. www.emseal.com | M M Systems Corp. www.mmsystemscorp.com |

| Manville Roofing www.johnsmanville.com Expand-O-Flash | Watson Bowman Assoc., Inc www.wbacorp.com |

| Sealing Strips | Poured-In-Place Sealants | Armored Assemblies |

|---|---|---|

| Sika Corp. www.sikacorp.com Sikadur Comblifex | Bostik Construction www.bostik.com | The D.S. Brown Co. www.arcat.com |

| Situra Inc. www.situra.com | Dow Corning Corp. www.dowcorning.com | M M Systems Corp. www.mmsystemscorp.com |

| Watson Bowman Assoc., Inc. www.wbacorp.com Wabocrete 101 System | General Electric Co. Silicon Products Division www.gesilicones.com | EMSEAL Joint Systems Ltd. www.emseal.com |

This listing is representative of manufacturers and not necessarily complete. Inclusion in this list is not an endorsement of any manufacturer or product.

gcpat.com | North America Customer Service: +1 (877) 423 6491

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 400, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-13

https://gcpat.com/en/solutions/products/bituthene-post-applied-waterproofing/tl-0011-expansion-joints-concrete