Product Description

BITUTHENE® Deck Prep is a low viscosity, two component, asphalt-modified urethane coating. It is used to level and repair rough concrete decks to which BITUTHENE® waterproofing membranes will be applied.

BITUTHENE® Deck Prep may also be used for detail areas as part of GCP waterproofing systems.. The VOC (Volatile Organic Compound) content is 10 g/L.

Architectural and industrial maintenance regulations limit the VOC content in products classified as architectural coatings. Refer to Technical Letters for the most current list of allowable limits.

Product Advantages

- Flexible—cures to rubber-like coating

- Low viscosity—easy to use, self leveling compound

- Fully adhered—seals to concrete substrate to provide temporary waterproofing layer

- No primer necessary—apply directly to dry, unprimed concrete

Use

BITUTHENE® Deck Prep is ideally suited as a:

- Leveling agent for rough concrete decks for new and rehab construction

- Non-structural repair material for defects in concrete decks for new and rehab construction

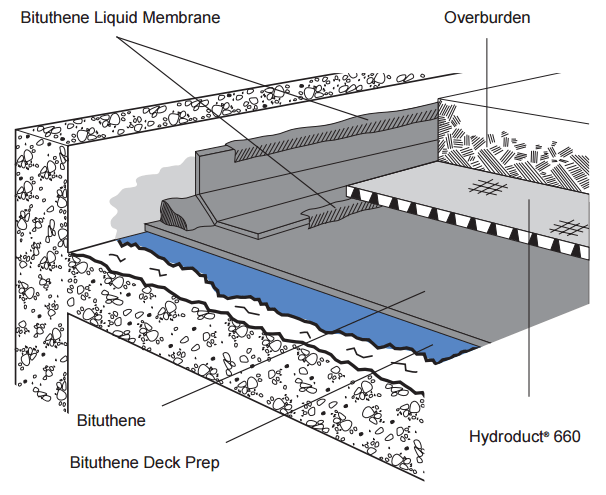

- Temporary waterproofing layer when used as part of the BITUTHENE® Deck System

- Primer layer for BITUTHENE® waterproofing membranes

- Details area as part of GCP waterproofing systems.

Compatibility

BITUTHENE® Deck Prep is completely compatible with all other BITUTHENE® products, PREPRUFE® products and with existing asphalt or coal tar-based waterproofing materials. It is also compatible with cured silicone and polyurethane sealants. It is not compatible with creosote, pentachlorophenol, linseed oil or polysulfide-based sealants. For further compatibility qualifications consult BITUTHENE® Technical Letters 4 and 10.

Application Procedures

Safety, Storage and Handling Information

BITUTHENE® products must be handled properly. Vapors from solvent based primers and mastic are harmful and flammable. Protection Board Adhesive is extremely flammable. For these products, the best available information on safe handling, storage, personal protection, health and environmental considerations has been gathered. SDS (Safety Data Sheet) and users should acquaint themselves with this information. Carefully read detailed precaution statements on product labels and the SDS before use.

Surface Preparation

All surfaces must be dry and free from dirt, grease, oil, dust or other contaminants. BITUTHENE® Deck Prep may be applied at temperatures of 25 °F (-4 °C) or above. Below 40 °F (5 °C), store in a warm place before application.

Mixing

Add the entire contents of the Part B container to Part A and mix for 3 to 5 minutes until uniform. Part A is black and Part B is clear. Take care to scrape material from the side and bottom of the containers to ensure thorough mixing. A low speed (150 rpm) mechanical mixer with flat paddle blades is required. Do not apply any material if streaks can be seen due to insufficient mixing.

Once mixed, BITUTHENE® Deck Prep should be poured directly onto the deck and spread with a squeegee over all areas that are to be waterproofed with BITUTHENE® waterproofing membranes. Apply BITUTHENE® Deck Prep within one hour after mixing. More time may be available at lower temperatures, however, at high temperatures thickening and curing may be faster. Material that has cured should be discarded.

BITUTHENE® Deck Prep should be applied in sufficient thickness to smooth all rough areas and fill all voids. The coverage rate is approximately 25 ft2/gal (0.6 m2/L) at 1⁄16 in. (1.5 mm) thickness. On very rough surfaces, the coverage could be lower. Apply material in thicknesses not to exceed ½ in. (13 mm) per coat. BITUTHENE® Deck Prep will adhere to dry, unprimed concrete. The product will support light foot traffic after an overnight cure. For interior applications, it may remain tacky even after fully cured. Apply BITUTHENE® waterproofing membranes directly to cured BITUTHENE® Deck Prep. No priming or conditioning is necessary.

Cleaning

Use appropriate personal protective equipment, and clean tools and equipment with mineral spirits before BITUTHENE® Deck Prep has cured. Mineral spirits is a combustible liquid and should be used only in accordance with the manufacturer’s safety recommendations. Do not use solvents to clean hands or skin.

Supply

| BITUTHENE® DECK PREP (PARTS A & B) PROPERTY | VALUE |

|---|---|

| Unit size | 4 gal (15.1 L) |

| Weight per unit | 44 lbs (20 kg) |

| Units per pallet | 24 |

Physical Properties

| PROPERTY | TYPICAL VALUE | TEST METHOD |

|---|---|---|

| Part A Color | Black | |

| Part B Color | Clear | |

| Mixture of Parts A and B Color | Black | |

| Solids content | 100% | ASTM D1644 |

| Elongation | 250% minimum | ASTM D412 |

| Peel strength | 5 lbs/in. (880 N/m) minimum | ASTM D903 |

| Flexibility, 180° bend over 1 in. T(25 mm) mandrel at -25 °F (-32 °C) |

Unaffected | ASTM D1970 |

gcpat.com | North America Customer Service: +1 (877) 423 6491

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate, and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations, and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

BITUTHENE and DECK PREP are trademarks, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2018 GCP Applied Technologies Inc. All rights reserved.

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 400, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-13

https://gcpat.com/en/solutions/products/bituthene-post-applied-waterproofing/bituthene-deck-prep