Project Profile

The 613,540-square-feet Commercial Bay project along the southern shore of the Waitemata Harbour in Auckland, New Zealand is set to be the largest mixed-use development in the city. Featuring a new 39-level office tower and 193,750 square feet of retail, Commercial Bay connects to an underground rail station and is expected to transform the waterfront from an aging mall into a hub for commerce, trade and transport.

With three basement levels more than 56 feet deep, the Commercial Bay project required a waterproofing solution that would work in a wet and muddy environment while addressing the complex architectural design. At the same time, the solution had to form a permanent, continuous seal against water and a barrier to resist the stress of ground settlement.

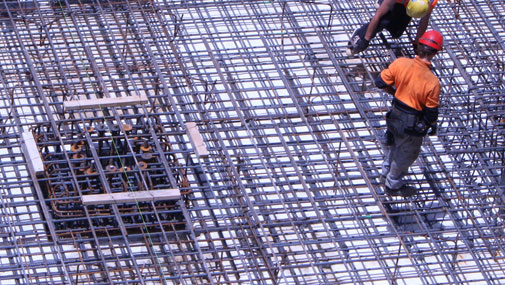

The new office tower was constructed among three existing buildings, making waterproofing a challenge due to the differential movement between buildings, which can damage the waterproofing if the design, or movement limiting structural designs, is not durable. Since the waterproofing application was scheduled to take place during winter, with its heavy rainfall and high chance of mud contamination, the specifier wanted a solution that would be unaffected by the climate, and would be fast and easy to install.

Given the specific requirements of the job, PREPRUFE® Plus pre-applied waterproofing membranes from GCP Applied Technologies (GCP) were selected to protect the project’s basement and transport connection link. Sansom Construction Systems Ltd., a construction and engineering company, delivered the solution after consulting with the developer Precinct Properties.

Designed with ADVANCED BOND TECHNOLOGY™ and dual adhesive ZIPLAP™ seams, PREPRUFE® Plus membranes form a unique, integral bond to poured concrete. This integral bond provides a robust barrier to water, moisture and gas and prevents both the ingress and lateral migration of water. PREPRUFE® Plus membranes are unique composite sheets comprised of a durable and flexible backing membrane, pressure-sensitive adhesive and patented, weather-resistant protective coating.

Another benefit of the PREPRUFE® Plus products is their absence of a release liner. This enables more efficient and reliable installation. PREPRUFE® Plus products require minimal cleaning before concrete pouring – just a quick hose off. The pre-applied waterproofing membranes can be trafficked immediately after application and are ready for immediate placing of reinforcement. PREPRUFE® Plus membranes with ZIPLAP™ seams allow for an adhesive-to-adhesive bond at membrane sheet overlaps and deliver superior performance in harsh conditions, without the need for specialized equipment, heat or power.

Results

Simpson Gumpertz & Heger (SG&H), the structural design consultants on the Commercial Bay development, specified PREPRUFE® Plus waterproofing membranes because they have a proven track record globally and in New Zealand. On the Commercial Bay project, the PREPRUFE® Plus solution helped reduce installation time, cost and waste.

Unlike alternatives that require special heating equipment to weld laps together or detailing tape to seal the laps, the PREPRUFE® Plus membrane’s easy roll and kick-out installation helped reduce installation time.

Adverse weather, mud contamination and delays to the construction schedule were major concerns for the developer, but since PREPRUFE® Plus membranes can be applied on damp surfaces, the development was able to meet a tight construction schedule. In addition, the ease of removing mud and water from the membranes’ surfaces meant the contractor did not have to worry about contamination issues.

PREPRUFE® Plus membranes made waterproofing a complex design much easier and faster. GCP Applied Technologies worked closely with SG&H during the design phase to identify project detailing ahead of time to help accelerate the waterproofing installation. PREPRUFE® Plus waterproofing was applied to provide comparatively simple but positive detailing on a multitude of piles, tiebacks, ground anchors and around penetrations. In addition, SG&H and GCP implemented strong quality assurance processes to ensure best practices and high installation quality. The robust waterproofing solution also helped rectify damages by other trades, such as during the installation of reinforcement, to maintain waterproofing integrity.

gcpat.com | North America Customer Service: +1 (877) 423 6491

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 400, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2025-05-13

https://gcpat.com/en/about/project-profiles/auckland-s-commercial-bay-transforms-waterfront