Overview

Save time, money and effort with high performance liquid waterproofing membrane. Our liquid waterproofing solutions are cold-applied, have a low odor and form a fully bonded membrane resisting lateral water migration.

Any building that doesn't keep out water won't be habitable for long. With cumbersome application techniques, waterproofing can bring an entire job site to a halt. SILCOR® liquid waterproofing provides a solution that's extremely durable without any of the hassle.

Products & Accessories

Products

Liquid applied waterproofing

Liquid applied waterproofing

- Product Name

- Description

- Key Benefits

- Applications Type

Liquid applied waterproofing

SILCOR® 900HA liquid waterproofing is a two-component, hand-applied seamless liquid waterproofing that is typically foot-trafficable after two hours of application. SILCOR® 900HA forms a fully-bonded waterproof membrane that is extremely durable, offers excellent wear and chemical resistance* and has a high tolerance against mechanical damage.

- Fast cure

- Fully bonded

- Non-flammable

- Low odor

- Plaza decks

- Split slabs

- Green roofs

- Planters

- PRMA applications

Liquid applied waterproofing

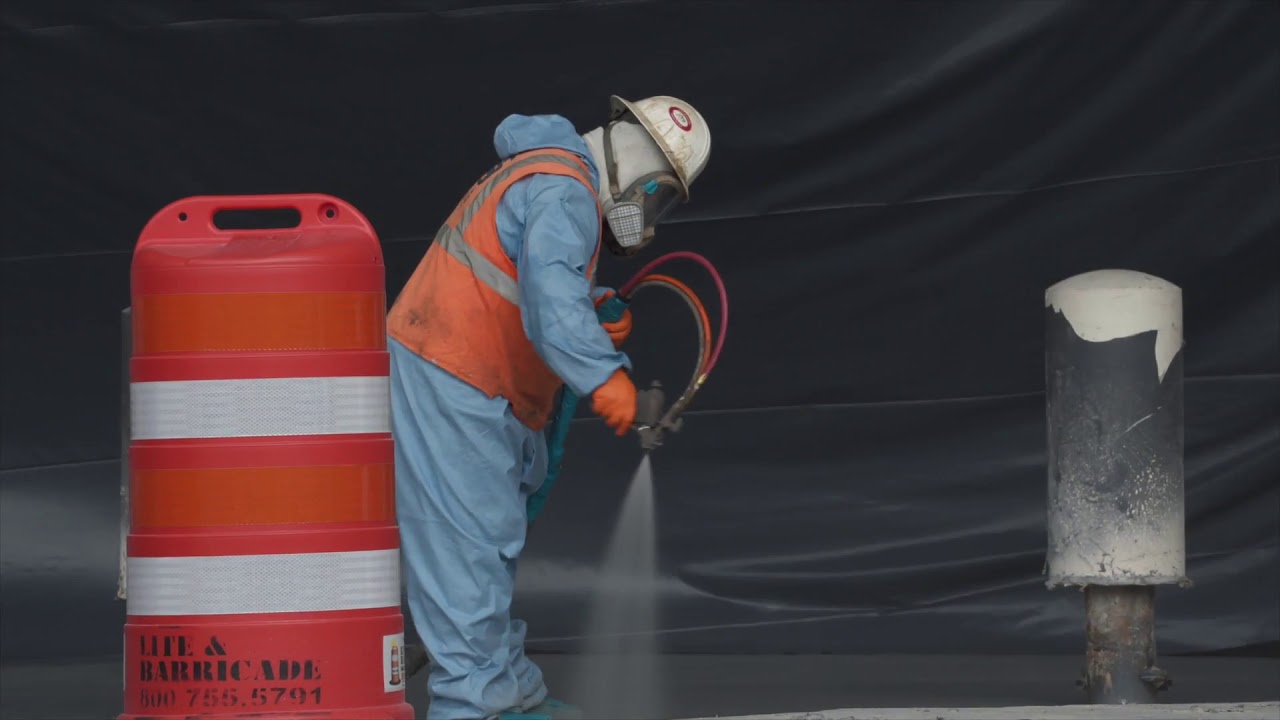

SILCOR® 900MP waterproofing is a premium performance, two-component, spray-applied, seamless waterproofing membrane that cures within two minutes to form a high-strength, elastomeric, and fully-bonded waterproof membrane.

- Fast Cure –Accepts foot traffic after two minutes

- Seamless – Continuous waterproofing integrity

- Productivity – Spray-applied for maximum coverage per day

- Plaza decks

- Split slabs

- Green roofs

- Planters

- PRMA

Accessories

Liquid applied waterproofing

Waterproofing accessories

Liquid applied waterproofing

Waterproofing accessories

- Accessory Name

- Description

- Key Benefits

- Applications Type

Liquid applied waterproofing

Waterproofing accessories

Liquid applied waterproofing

Waterproofing accessories

SILCOR® Fast Set Primer is a two-component fast curing, short recoat time urethane primer for concrete substrates specifically designed for SILCOR® liquid waterproofing membranes.

- Fast curing with short recoat time : 20 minute recoat time at 70°F (21°C)

- Easy to apply by spray or roller or brush

- Convenient for large size jobs (10 gallon kit)

Liquid applied waterproofing

Waterproofing accessories

Liquid applied waterproofing

Waterproofing accessories

SILCOR® Primer EPF is a two-component fast curing, short recoat time epoxy primer for concrete substrates specifically designed for SILCOR® liquid waterproofing membranes.

- Can be placed over green concrete or 7 days cure concrete, when it is used with SILCOR® 900MP

- Fast curing with short recoat time

- Excellent adhesion exceeds concrete cohesive strength

Liquid applied waterproofing

Liquid applied waterproofing

SILCOR® Top Coat 70 is a two-component, UV protective coating, formulated specifically to protect SILCOR® waterproofing membranes in permanently exposed upturn and flashing applications.

- Prevents discoloration of SILCOR® membranes in upturn and flashing applications

- Color stable and UV resistant

- Frost and weather resistant

- Plaza decks

- Split slabs

- Green roofs

- Planters

- PRMA applications

Related

briefcase

Click to find out more...

READ MOREOctober 18, 2017

Top Five Reasons to Use Liquid Waterproofing

Architects are increasingly specifying liquid waterproofing membranes to extend the life of podium decks and roofs. Contractors are also finding they prefer these easy-to-install solutions over sheet-...

READ MOREOctober 23, 2017

Green roofs are growing like wild

From Chicago City Hall to Tokyo’s Imperial Hotel, green roofs are growing like wild. They’ve been well established in Europe for years, and now have taken hold in the U.S., with millions of square fee...

READ MOREMarch 16, 2018

Top questions to ask when designing a green roof

We all know the economic and environmental benefits of green roofs, but how do you ensure that your client’s vision of a green roof is realized? Today we had the pleasure of talking with Nick Smith of...

READ MOREFebruary 12, 2018

Best practices for waterproofing buried roofs

What are buried roofs? Typically part of an under-garden structure or landscaped area, a buried roof is either part of a basement that extends beyond the line of the main elevations, or an elevated d...

READ MORENovember 15, 2017

Make the most of outdoor space

Developers are increasingly finding novel ways to maximize outdoor space, creating inviting terraces and roof decks that offer sweeping views as well as more living area for a variety of uses. This ma...

READ MORE