/ concrete / mix design

Introduction

CONCERA® SA8080 is a patented rheology modifying polycarboxylate based ASTM C494 Type A and F high range water reducer (HRWR) that enables the production of Control Flow Concrete, a highly flowable concrete with minimal or no segregation using unmodified conventional mix designs. Control Flow Concrete’s typically have slump flow values in the 16"-25" (406 to 635 mm) range and may require minimal external energy to properly consolidate. CONCERA® SA8080 is a component of GCP’s Control Flow Concrete System and is typically used as a standalone HRWR. It does not need to be used with other mid or high range water reducers. CONCERA® SA8080 imparts many desirable properties to Control Flow Concrete including segregation resistance, stability, improved passing and filling ability, excellent tolerance to moisture variation and extended slump life. CONCERA® SA8080 also produces concrete with consistent, predictable slump flow and air control properties. CONCERA® SA8080 typically has minimal impact on other concrete properties including early and later age compressive strength and drying shrinkage, while initial time of set and total bleed may slightly increase.

ASTM C 1611-Standard Test Method for Slump Flow of Self-Consolidating Concrete (SCC) details a qualitative visual test procedure for measuring rheology, stability and segregation resistance properties of highly flowable concrete and SCC. Test procedure includes a visual inspection of the concrete spread after the slump flow test is completed. Visual inspection includes observing the distribution of coarse aggregate within the concrete spread and mortar fraction and bleeding characteristics around the perimeter of the spread. Finally, a Visual Stability Index (VSI) value is assigned to the concrete spread using 0-3 criteria as detailed below.

Visual Stability Index Values

- 0 = HIGHLY STABLE -No evidence of segregation or bleeding.

- 1 = STABLE - No evidence of segregation and slight bleeding observed as a sheen on the concrete mass.

- 2 = UNSTABLE - A slight mortar halo ≤0.5 in. (≤ 10 mm) and/or aggregate pile in the center of the concrete mass.

- 3 = HIGHLY UNSTABLE - Clearly segregating by evidence of a large mortar halo ≥ 0.5 in. (≥ 10 mm) and/or a large aggregate pile in the center of the concrete mass.

A CONCERA® SA8080 field test evaluation program using an array of 3500-6500 psi (24.2-44.8 Mpa) mix designs containing different types and quantities of cements, pozzolans and fine and coarse aggregates was conducted at several test sites in North America. The mix design and HRWR test matrix included:

- Conventional 8" (203 mm) slump using polycarboxylate based HRWR

- Highly flowable 16-25" (406 to 635 mm) slump flow using polycarboxylate based HRWR

- Control Flow Concrete 16-25" (406 to 635 mm) slump flow using CONCERA® SA8080 HRWR

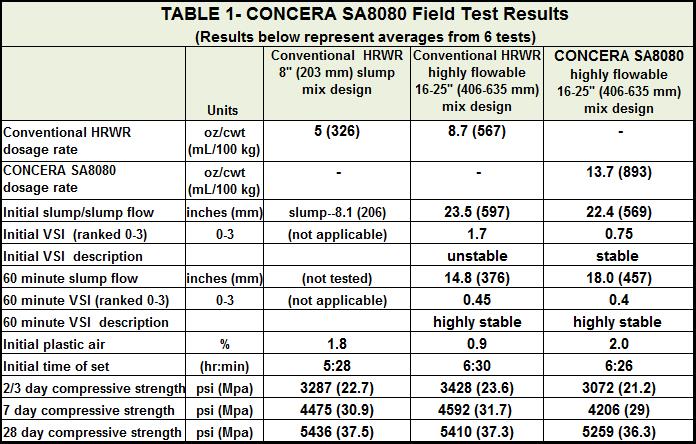

Table 1 above details summary of test results including initial slump flow, VSI, plastic air, initial time of set, early, 7, 28 day compressive strength along with 60 minute slump flow and VSI. Field test results clearly show CONCERA® SA8080 produces highly flowable, stable, segregation resistant concrete with excellent slump retention properties over 60 minutes and minimal impact on other pertinent plastic and hardened concrete properties.

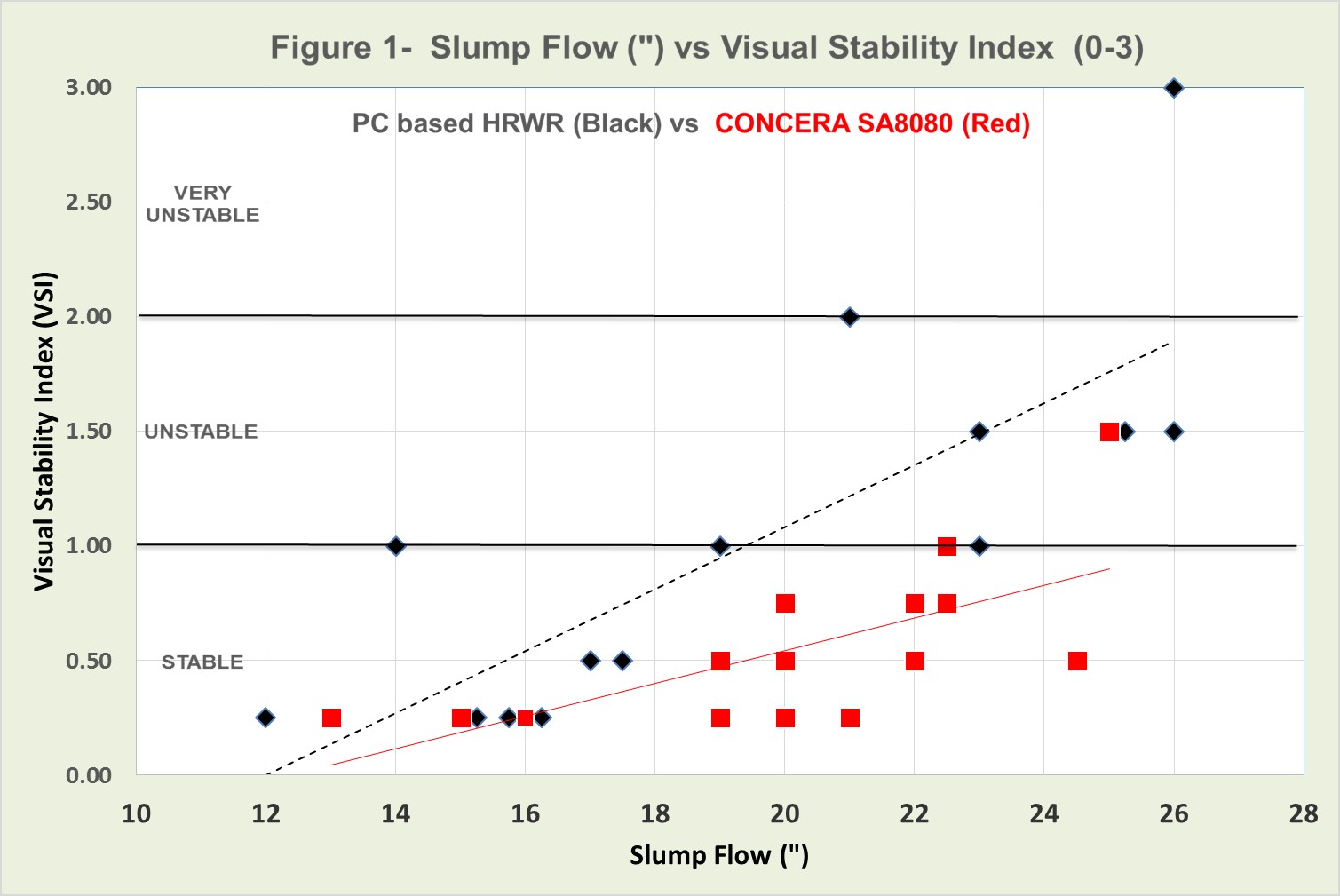

Figure 1 below further details polycarboxylate based HRWR (black) and CONCERA® SA8080 (red) concretes visual stability index (VSI) values over a range of slump flows. CONCERA® SA8080 concretes consistently show better (lower) visual stability index values when compared to highly flowable polycarboxylate based HRWR concrete with all VSI‘s < 1. Note: ACI 237-Self Consolidating Concrete document states – A VSI rating <1 is an indication that the highly flowable concrete is stable. ACI 237 further states that VSI ratings are subjective and should be used primarily as a quality control tool, rather than as acceptance/rejection criteria for a specific mix design.

When CONCERA® SA8080 is added to a conventional "off the shelf" mix design, and additional incremental improvements to the overall rheology, segregation resistance, stability or other properties are desired, relatively minor and inexpensive mix design modifications can be made. Several of these mix design adjustments are detailed below, with implications related to making a specific adjustment detailed in parentheses. It is highly recommended CONCERA® SA8080 Control Flow Concrete be tested prior to job startup using applicable mix designs and materials:

- Reduce total coarse aggregate content (increases drying shrinkage)

- Reduce nominal coarse aggregate size (increases drying shrinkage)

- Optimize coarse aggregate particle shape/angularity

- Optimize coarse aggregate gradation, avoid severely gap graded coarse aggregate

- Increase fine agg, reduce coarse agg content (water demand and shrinkage impact)

- Increase mortar and/or paste fraction (water demand and shrinkage impact)

- Slightly increase total cementitious content (cost increase)

- Incorporate or increase the percentage of fly ash in the mix design

- Reduce slump flow to low end of 16-25" (406 to 635 mm) range (workability impact)

- Slightly increase plastic air content (strength impact)

- Slightly reduce water content, increase CONCERA® SA8080 dosage rate

In summary, a widespread North America based field test program confirmed CONCERA® SA8080 enables the production of 16-25" (406 to 635 mm) Control Flow Concrete with minimal or no segregation using typically unmodified conventional mix designs. CONCERA® SA8080 imparts many other desirable properties to Control Flow Concrete including improved passing and filling ability, tolerance to moisture variation, consistent slump flow and slump flow properties and minimal impact on compressive strength and set time. Several minor mix design modifications can also be tested and implemented if additional improvements to overall rheology, stability and segregation resistance properties are desired.

gcpat.com | North America Customer Service: +1 (877) 423 6491

We hope the information here will be helpful. It is based on data and knowledge considered to be true and accurate and is offered for consideration, investigation and verification by the user, but we do not warrant the results to be obtained. Please read all statements, recommendations and suggestions in conjunction with our conditions of sale, which apply to all goods supplied by us. No statement, recommendation, or suggestion is intended for any use that would infringe any patent, copyright, or other third party right.

CONCERA is a trademark, which may be registered in the United States and/or other countries, of GCP Applied Technologies Inc. This trademark list has been compiled using available published information as of the publication date and may not accurately reflect current trademark ownership or status.

© Copyright 2017 GCP Applied Technologies Inc. All rights reserved.

GCP0083 TB-1701-0417

GCP Applied Technologies Inc., 2325 Lakeview Parkway, Suite 400, Alpharetta, GA 30009, USA

GCP Canada, Inc., 294 Clements Road, West, Ajax, Ontario, Canada L1S 3C6

This document is only current as of the last updated date stated below and is valid only for use in the United States. It is important that you always refer to the currently available information at the URL below to provide the most current product information at the time of use. Additional literature such as Contractor Manuals, Technical Bulletins, Detail Drawings and detailing recommendations and other relevant documents are also available on www.gcpat.com. Information found on other websites must not be relied upon, as they may not be up-to-date or applicable to the conditions in your location and we do not accept any responsibility for their content. If there are any conflicts or if you need more information, please contact GCP Customer Service.

Last Updated: 2023-06-28

https://gcpat.com/en/solutions/products/concera-all-one-admixture/tb-1701-concera-sa8080-control-flow-technical-bulletin